Method for preparing squid surimi

A production method and technology of squid, applied in food preparation, application, food science, etc., can solve the problems of squid muscle tissue toughness, difficult to maintain a complete shape, and limited development and utilization, so as to reduce toughness, increase viscosity, and maintain a complete shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

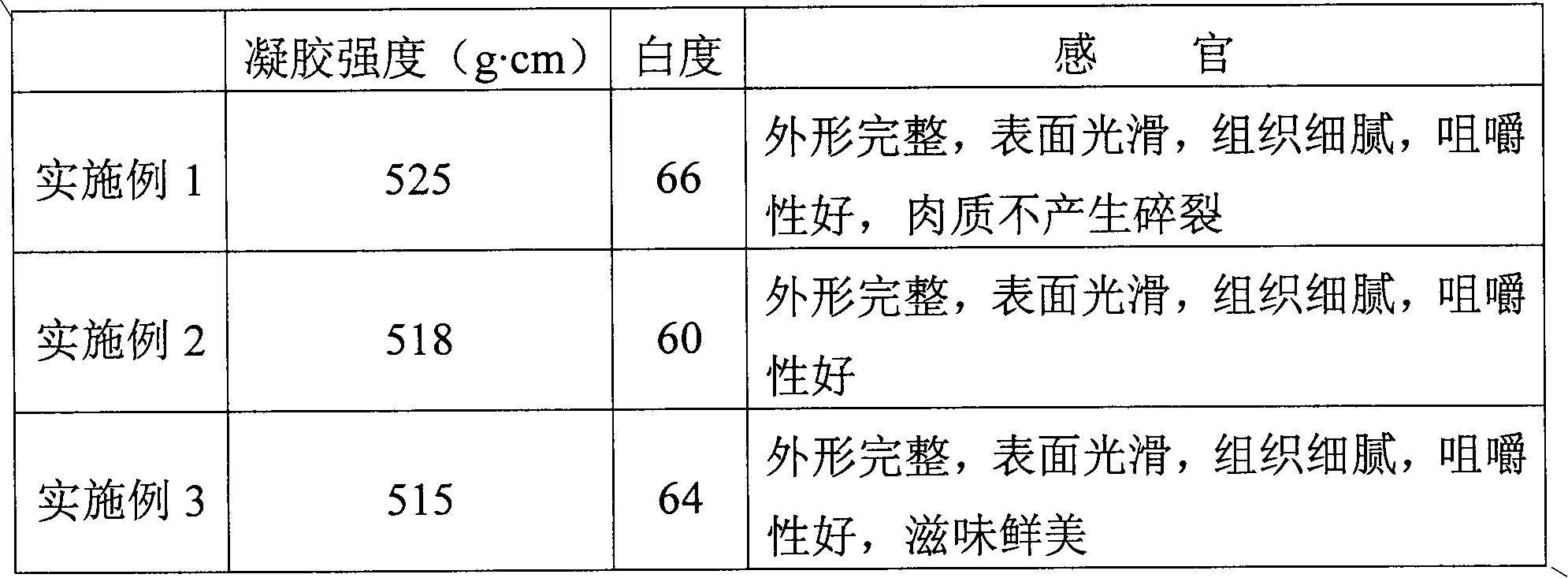

Embodiment 1

[0018] A, pretreatment: peel off the skin, remove the viscera, wash the squid carcass with clear water, and cut it into blocks;

[0019] B, enzymolysis and tenderization: adopt the compound protease enzymolysis solution (both weight ratio is 2: 1) of alkaline protease and trypsin to act on (A) block squid block substrate that step obtains, carry out impregnation enzymolysis For tenderization, the weight percent concentration of the compound protease hydrolyzate is 0.05%, the pH value is 8.5, the action temperature is 50°C, and the action time is 85 min;

[0020] C. Extrusion: put the tenderized squid pieces into the extruder, the screw speed is 320r / min, the feeding speed is 8kg / min, the barrel temperature is 125°C, and the micronization treatment is carried out;

[0021] D, beating: Put the extruded fish into the beating machine, add salt, sugar, starch, seasoning and other auxiliary materials, and be beating for 25 minutes;

[0022] E. Forming: According to the type of suri...

Embodiment 2

[0029] A, pretreatment: peel off the skin, remove the viscera, wash the squid carcass with clear water, and cut it into blocks;

[0030] B, enzymolysis and tenderization: adopt the composite protease enzymolysis solution (both weight ratio is 1: 1) of alkaline protease and trypsin composition to act on (A) block squid piece substrate that obtains, carry out impregnation enzymolysis For tenderization, the weight percent concentration of the compound protease hydrolyzate is 0.06%, the pH value is 8.6, the action temperature is 45°C, and the action time is 75 minutes;

[0031] C. Extrusion: put the tenderized squid pieces into the extruder, the screw speed is 300r / min, the feeding speed is 9kg / min, the barrel temperature is 120°C, and the micronization process is carried out;

[0032] D, beating: Put the extruded fish into the beating machine, add salt, sugar, starch, seasoning and other auxiliary materials, and be beating for 25 minutes;

[0033] E. Forming: According to the ty...

Embodiment 3

[0040] A, pretreatment: peel off the skin, remove the viscera, wash the squid carcass with clear water, and cut it into blocks;

[0041] B, enzymolysis and tenderization: adopt the composite protease enzymolysis solution (both weight ratio is 1: 2) of alkaline protease and trypsin to act on (A) block squid block substrate that step obtains, carry out impregnation enzymolysis For tenderization, the weight percent concentration of the compound protease hydrolyzate is 0.08%, the pH value is 8.4, the action temperature is 48°C, and the action time is 80 min;

[0042] C. Extrusion: put the tenderized squid pieces into the extruder, the screw speed is 340r / min, the feeding speed is 8.5kg / min, the barrel temperature is 130°C, and the micronization treatment is carried out;

[0043] D, beating: Put the extruded fish into the beating machine, add salt, sugar, starch, seasoning and other auxiliary materials, and be beating for 25 minutes;

[0044] E. Forming: According to the type of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com