Lateral punching device

A lateral punching and cutting knife technology is applied in the field of punching devices for laterally punching and cutting products to be cut to achieve the effects of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

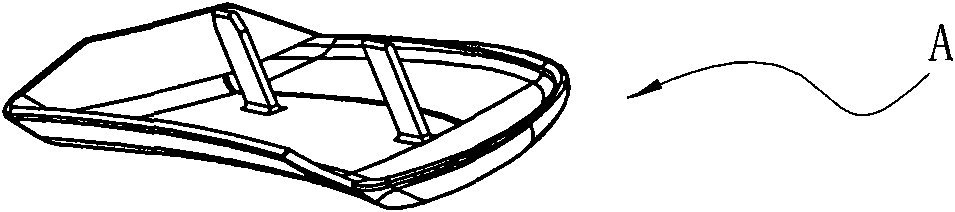

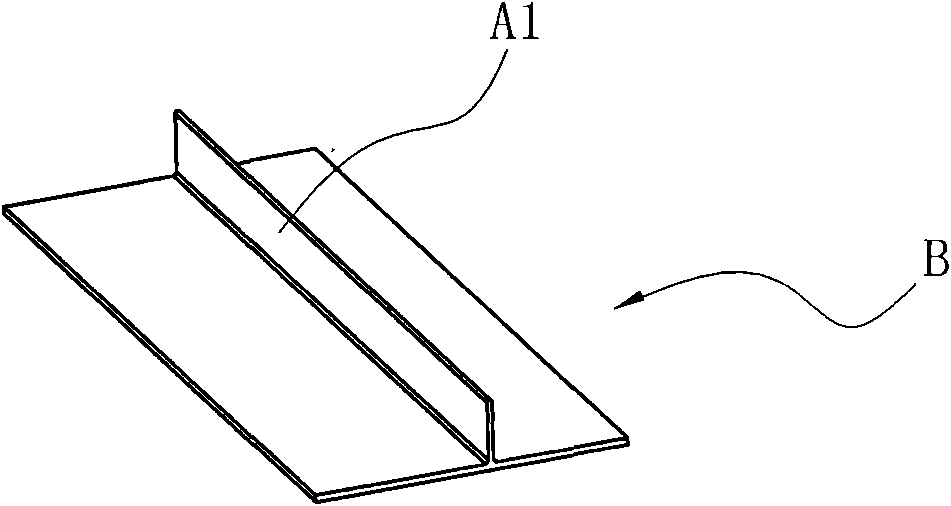

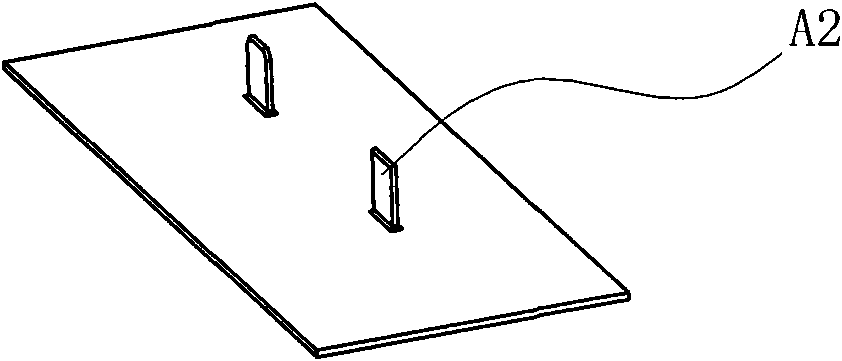

[0027] like Figure 1 to Figure 3 as shown, figure 1 It is a triangular bright strip A for auto parts. The lower surface of the extruded semi-finished product B has ribs A1 and forms a T-shaped structure as a whole. Now it is necessary to punch off part of the ribs to form two separate sheet-shaped chucks. A2. In order to achieve the above requirements, a lateral punching device is now used, such as Figure 4 As shown, the device includes an upper template 1, a lower template 2, and a guide post 3 arranged between the upper template 1 and the lower template 2, wherein the upper template 1 can move downward through the guide post 3, and an inclined frame is installed on the upper template. The wedge 4 and the binder plate 5 are fixed with a guide rail 6 on the lower formwork 2, and a slide block 7 is installed on the guide rail 6. The slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com