Multi colour lighter casing and paster, and producing method thereof

A manufacturing method and lighter technology, applied in the direction of combustion method, combustion ignition, igniter with fuel, etc., can solve the problems of high cost, low pass rate, easy fading, etc., and achieve the effect of low cost and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention will now be described in detail with reference to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

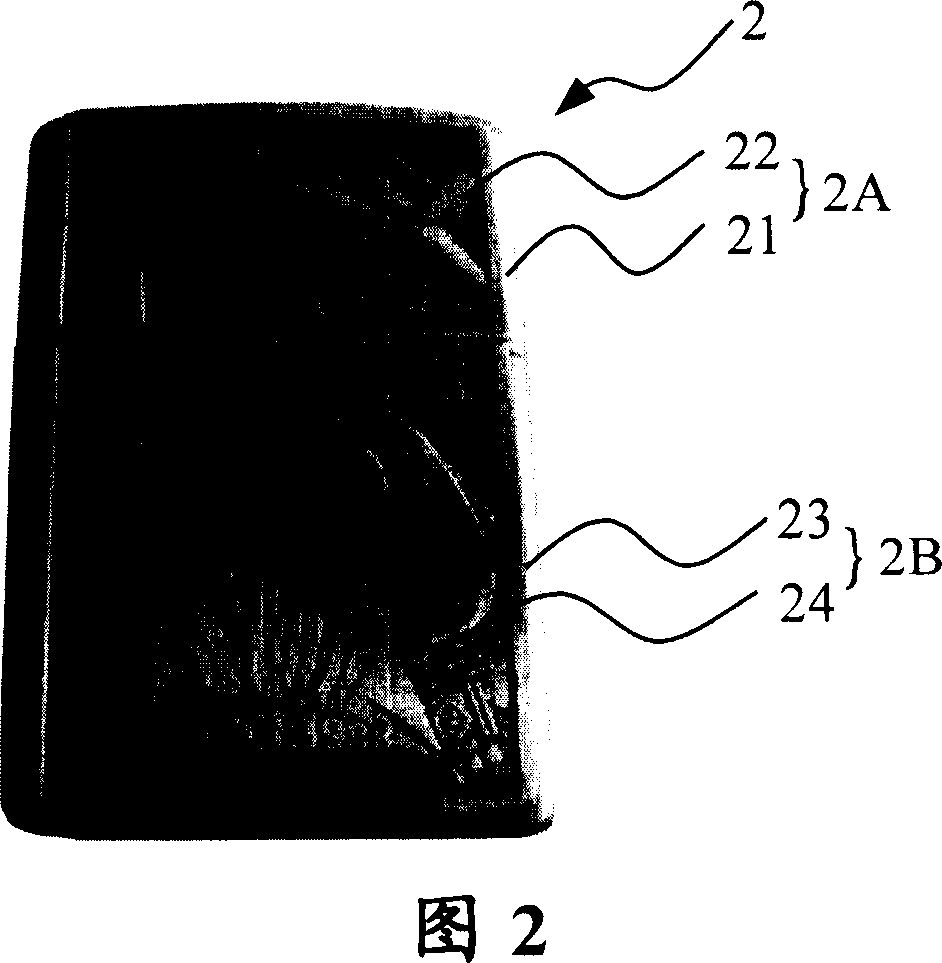

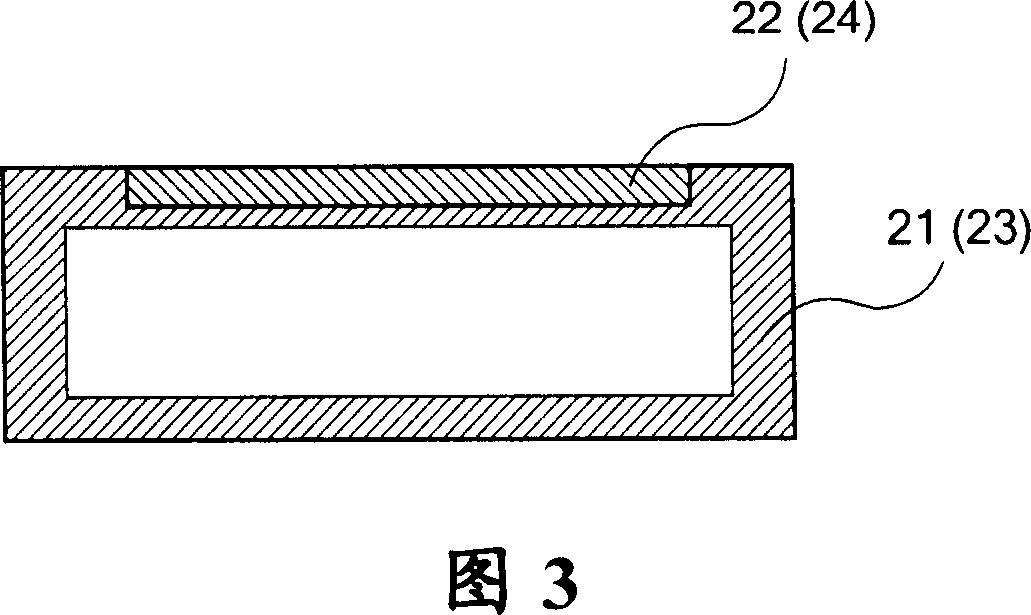

[0044] Referring to FIG. 2 , it is a schematic diagram of a lighter housing according to the present invention. This lighter casing 2 comprises an upper casing 2A and a lower casing 2B, and the upper and lower casings 2A and 2B respectively include casing bases 21, 23 made of metal and decorative parts 22, 24 made of metal, and the decorative parts 22, 24 are fixedly arranged. on the housing base 21 , 23 . Referring to FIG. 3 , the decorative components 22 , 24 can be embedded on the shell bases 21 , 23 by means of assembly such as bonding, welding, riveting, tight fitting, extrusion, etc., or a combination thereof.

[0045] Wherein, the metal color of the decorative parts 22 , 24 is different from the metal color of the shell base 21 , 23 . For example, the casing bases 21 and 23 can be made of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com