Attached switch in automobile instrument stepper motor

A technology attached to switches and stepping motors, applied in the field of detection methods, can solve problems such as pointer shaking, stepping motors without holding torque, and pointer rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

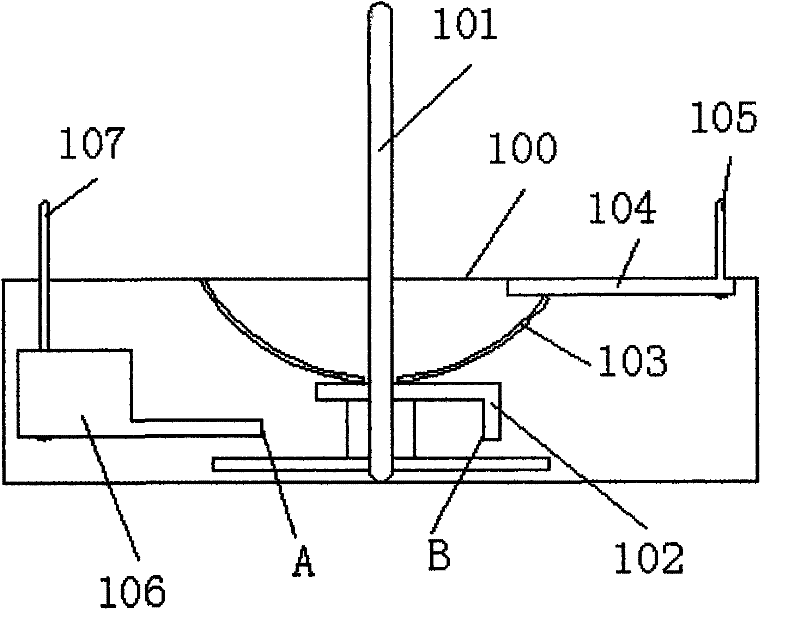

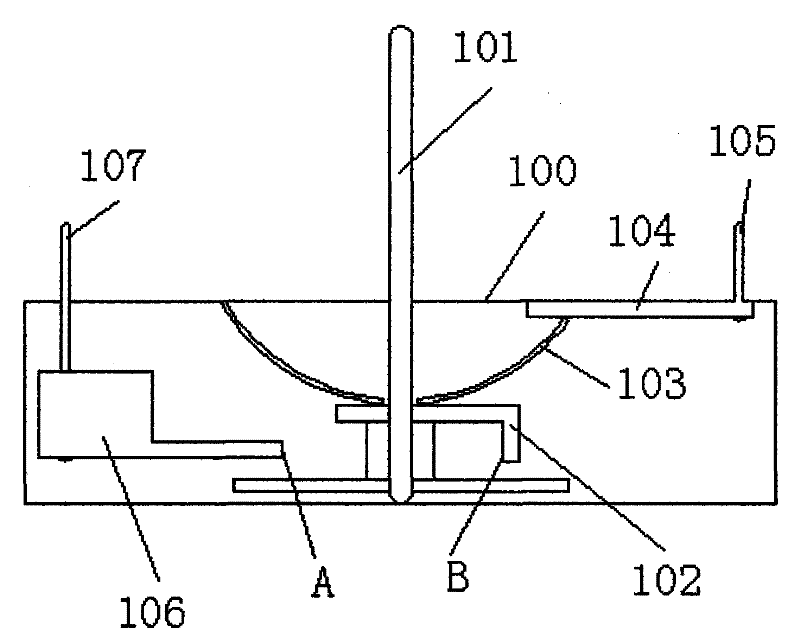

[0008] Concrete embodiment and coordinate accompanying drawing are described as follows:

[0009] In the stepper motor 100 of the instrument, a metal gear 102 is tightly pressed on the output shaft 101. The output shaft passes through the center hole of the ingot spring 103. The metal gear 102 is pressed on the ingot spring 103, and the ingot spring 103 is pressed on the thin metal sheet 104 On the top, the thin metal sheet 104 is tightly attached to the inside of the shell and welded to the terminal pin 105 protruding out of the shell; the thick metal plate 106 is inserted vertically into the inside of the shell and welded to the terminal pin 107 protruding out of the shell, point A of the thick metal sheet is connected to Metal block B point is exactly the contact of switch, and terminal pin 105, terminal pin 107 are exactly two ends of switch.

[0010] When the output shaft with the pointer rotates to a certain position in the direction of returning to zero, the point B of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com