Patents

Literature

35results about "Provision for operation by null methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

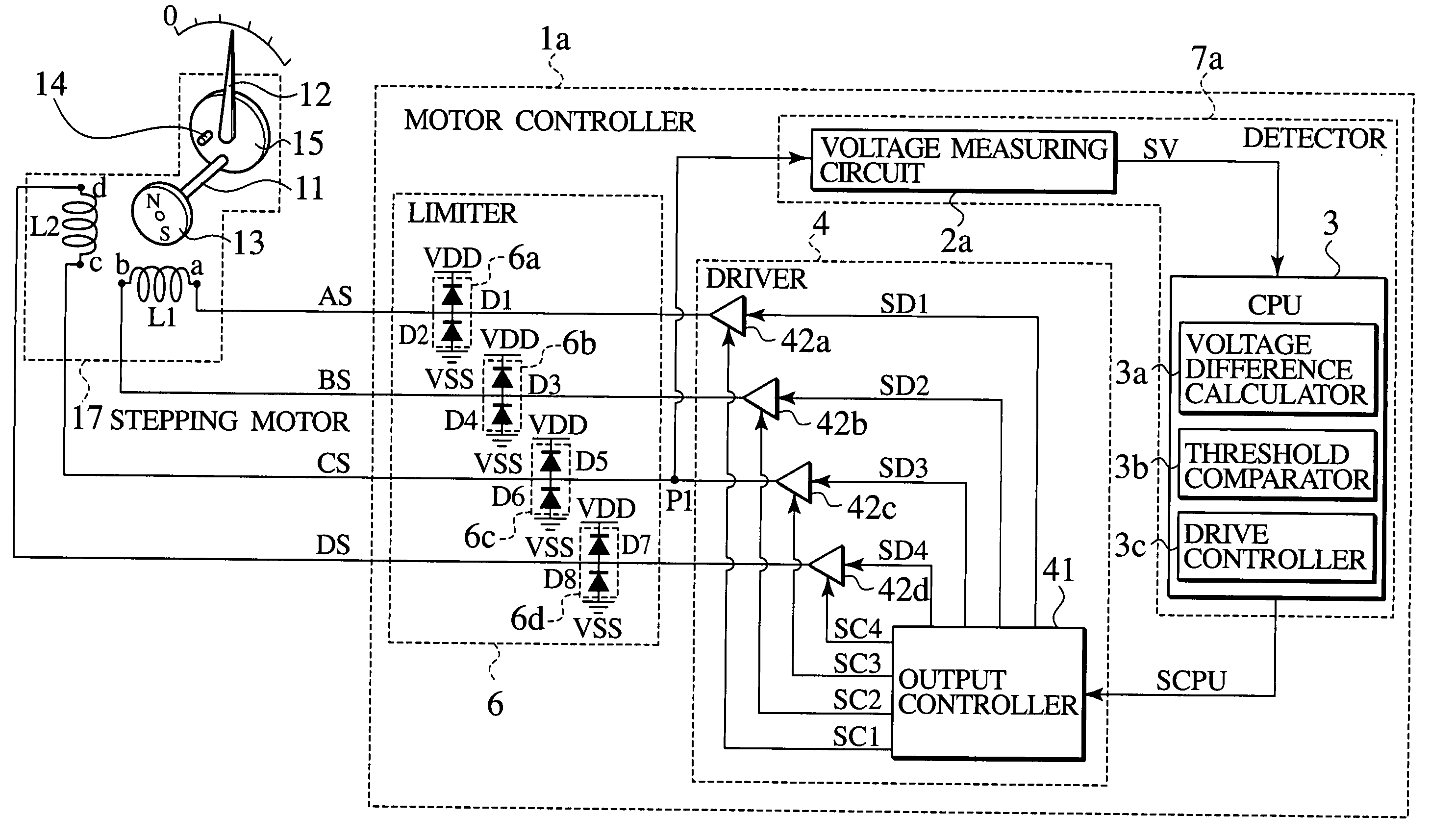

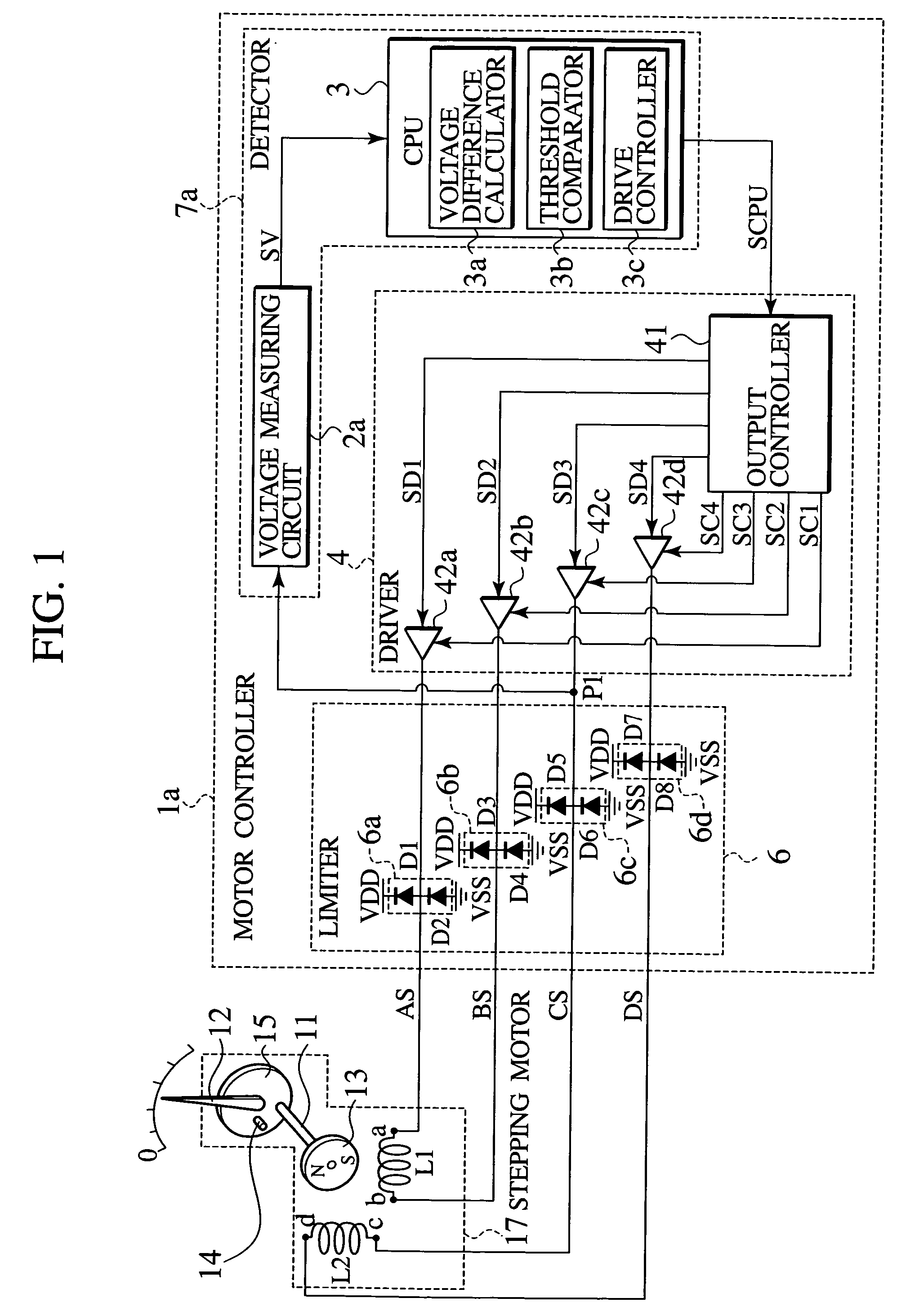

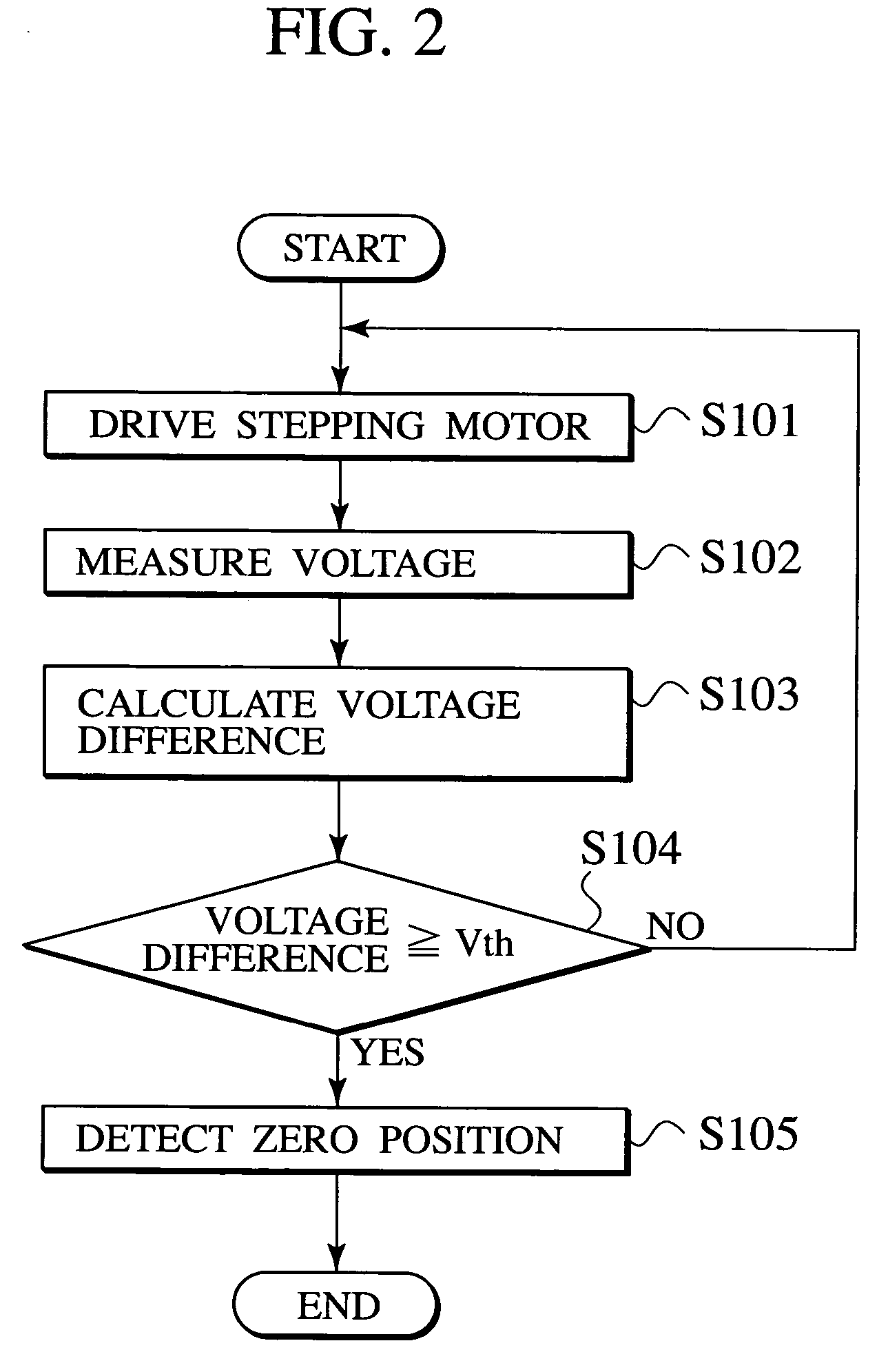

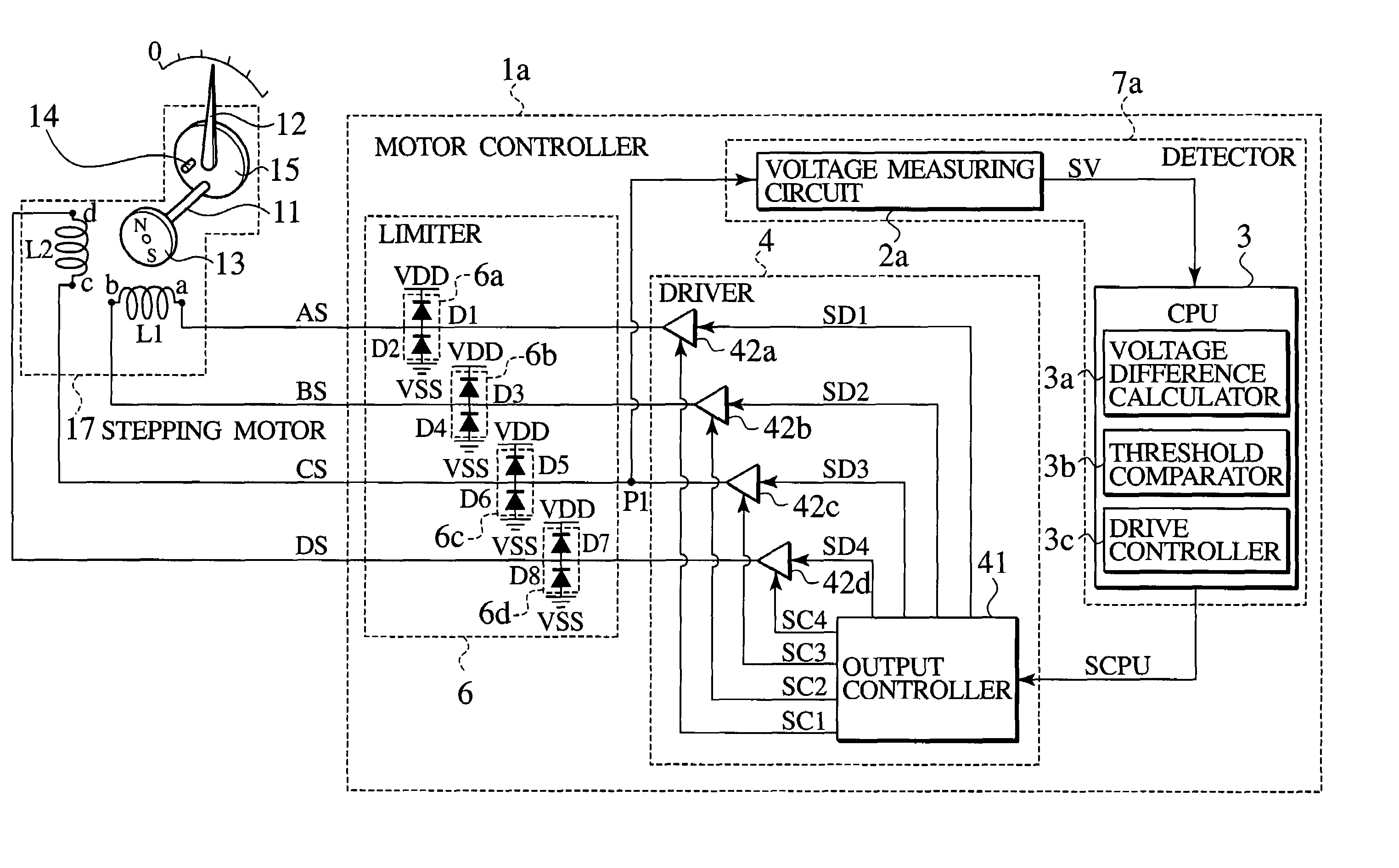

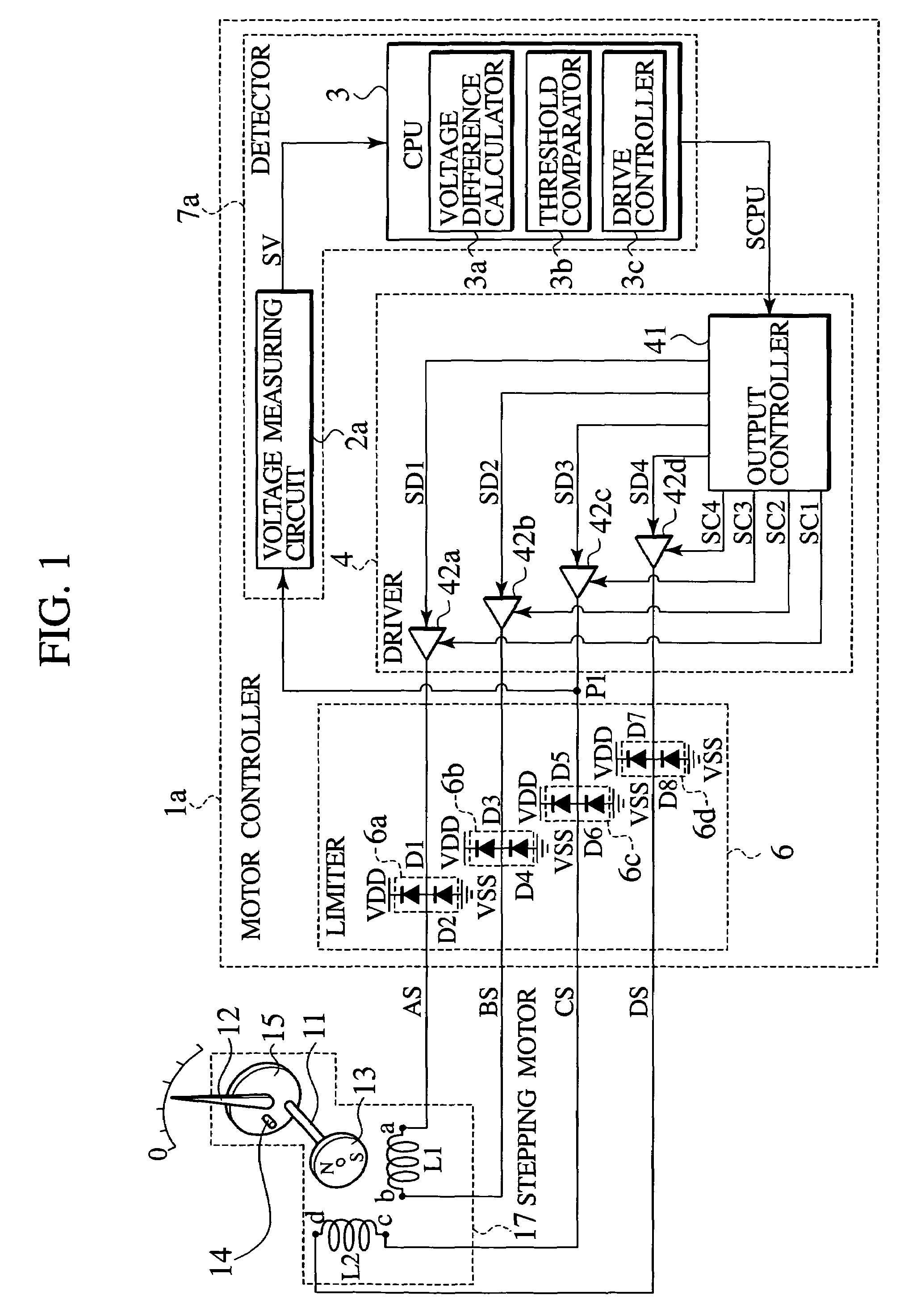

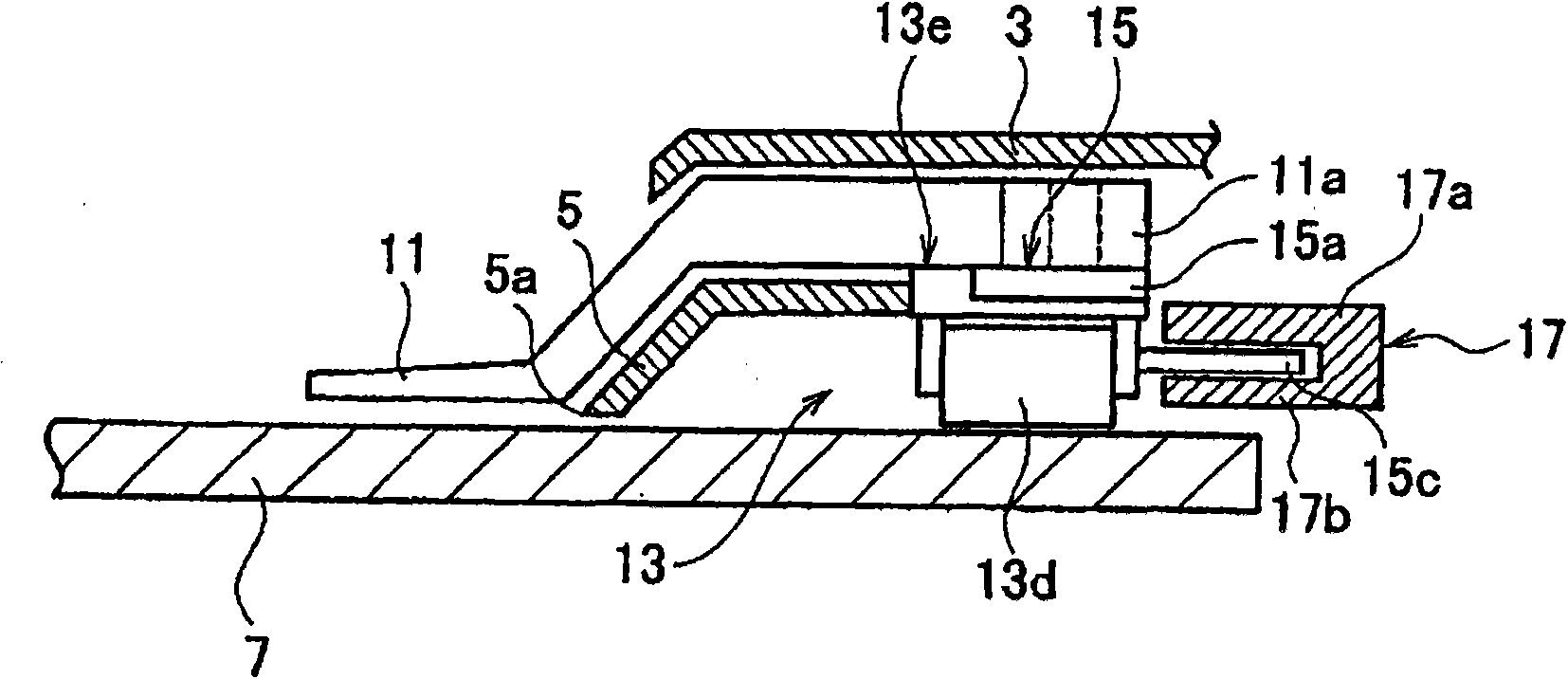

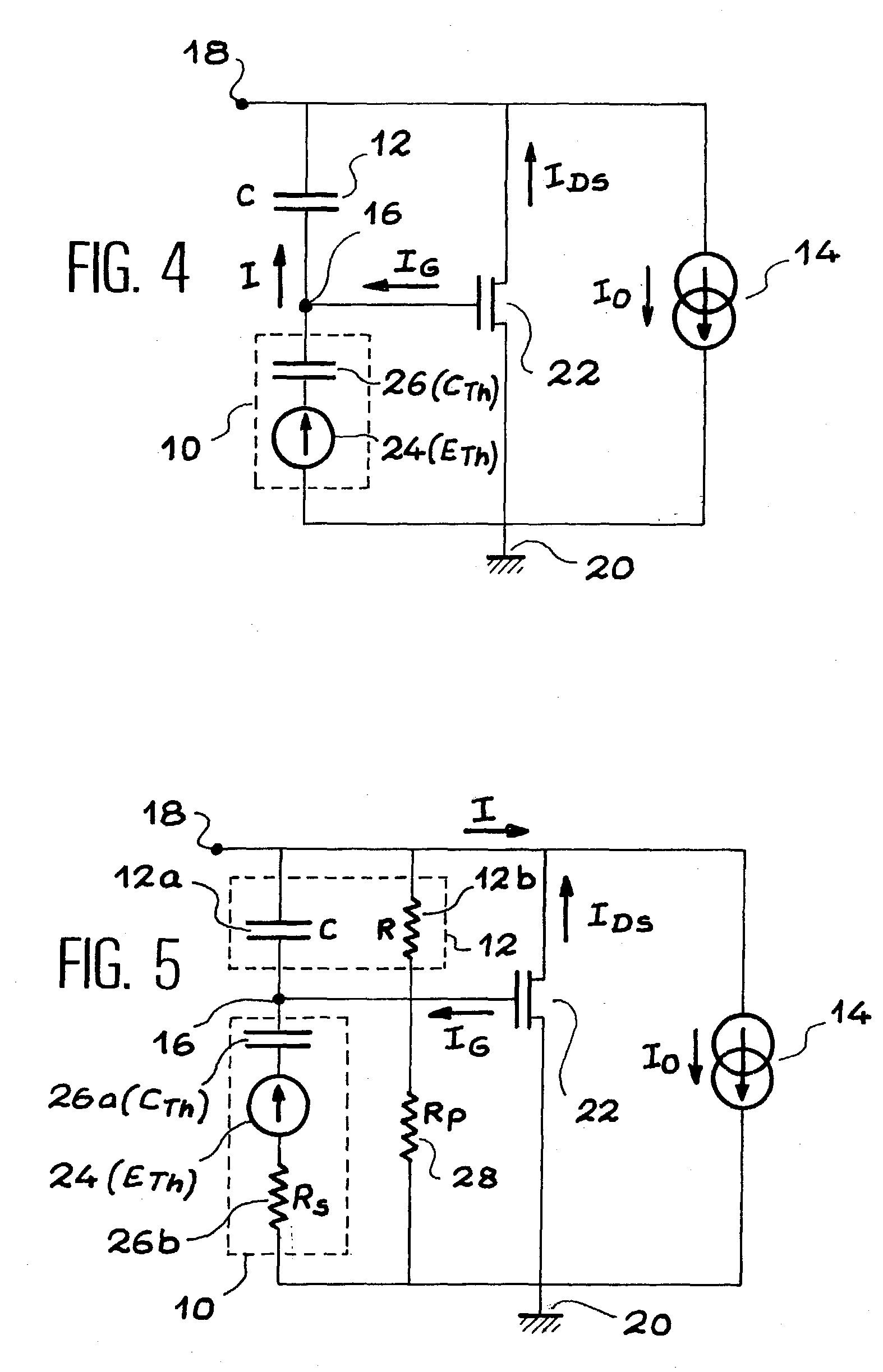

Motor controller, semiconductor integrated circuit, indicating instrument and method for controlling a motor

InactiveUS20040189237A1Emergency protective circuit arrangementsSolid-state devicesControl signalMotor controller

A motor controller comprising, a detector configured to perform a difference processing for information relating to a counter electromotive force and an induced electromotive force generated by a stepping motor, and to generate a driving control signal based on a result of the difference processing, and a driver configured to drive the stepping motor based on the driving control signal.

Owner:KK TOSHIBA

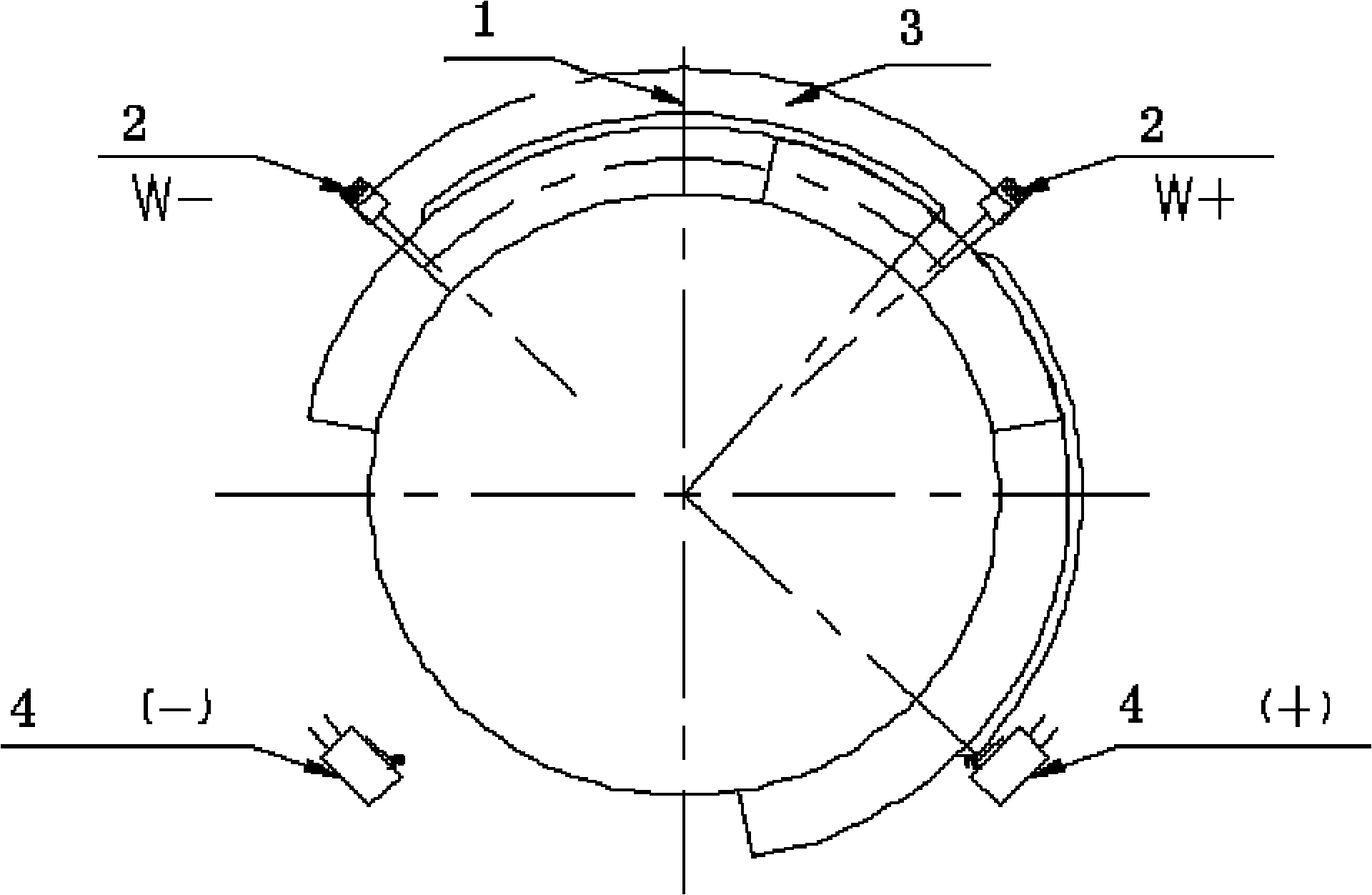

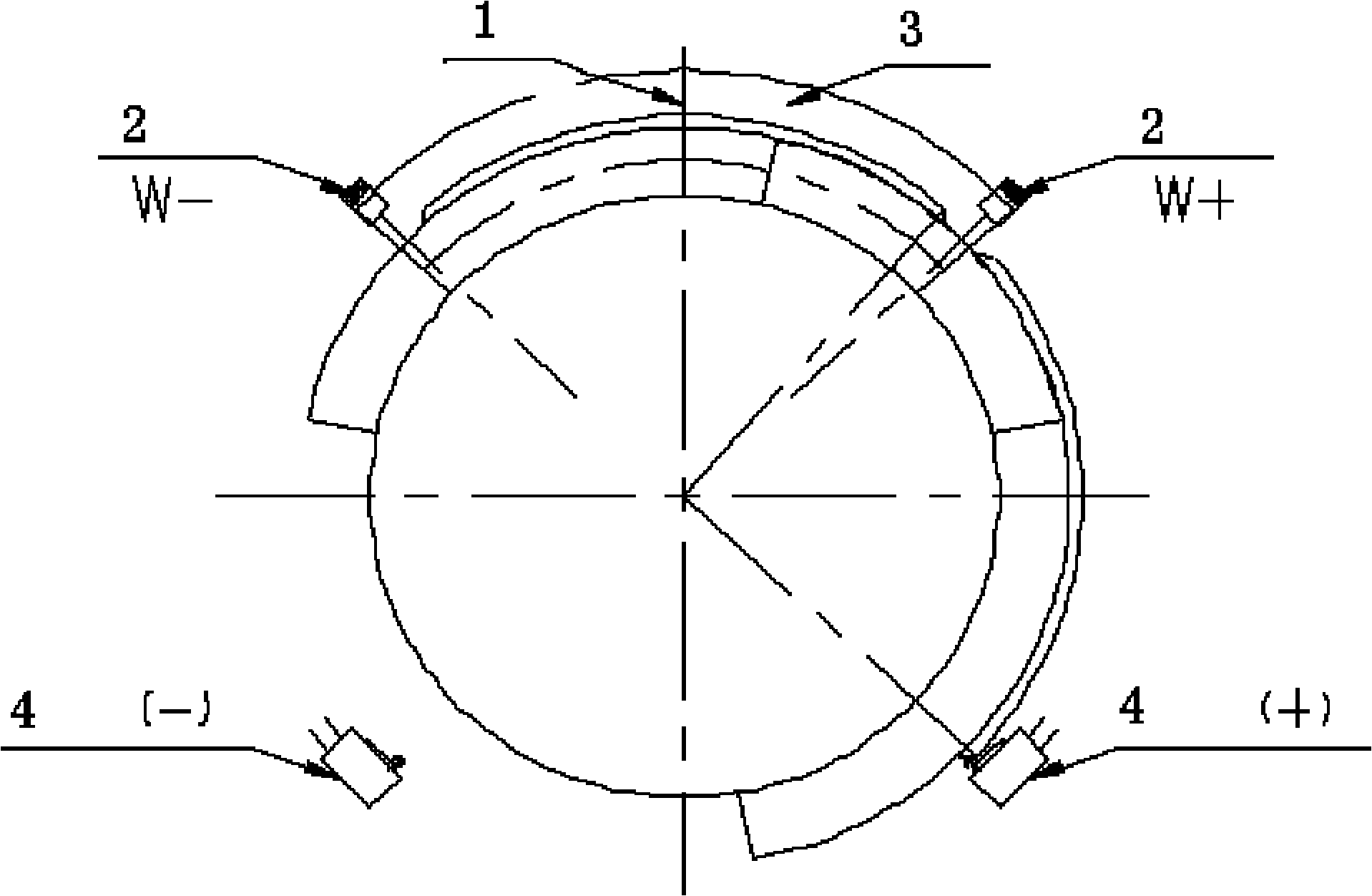

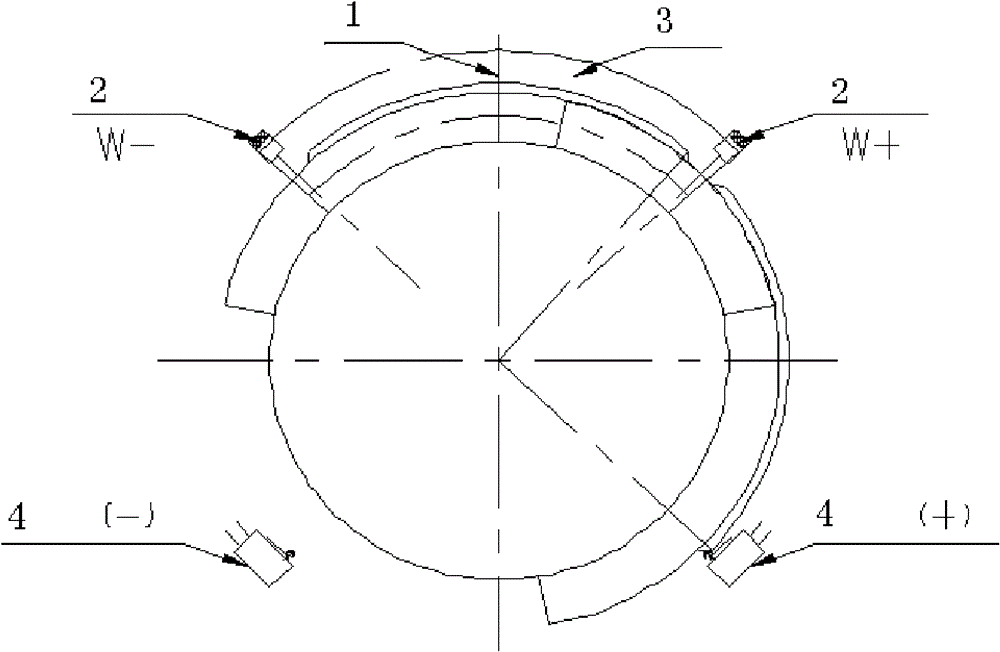

Automatic zeroing method and equipment for incremental sensor

The invention relates to an automatic zeroing method and automatic zeroing equipment for an incremental sensor. The method comprises the following steps of: (1) arranging a zero point detection device at the middle position of a motion stroke; (2) symmetrically arranging switches W+ and W- in the stroke directions on the two sides of a zero point; (3) arranging a zero point-centered baffle sheet on a rotating body, wherein a signal is 1 when a photoelectric switch is baffled by the baffle sheet, while the signal is 0 when the photoelectric switch is not baffled by the baffle sheet; (4) continuously detecting the values of the W+ and W- during zero-crossing by an electric control system; (5) continuously checking a zero point signal, zeroing the reading of an angular sensor when the zero point signal takes effect, or automatically zeroing the reading of the angular sensor by hardware when the zero point signal takes effect; and (6) indicating that zeroing fails if detecting that the states of the W+ and W- are changed into 01 from 10, or 10 from 01 but not detecting the zero point signal during the zero-crossing, and zeroing again. The method and the equipment overcome the defects of the prior art and can quickly judge the zeroing direction, shorten a redundancy stroke and realize high-efficiency automatic zeroing.

Owner:NANJING NAIERSI PHOTOELECTRIC INSTR

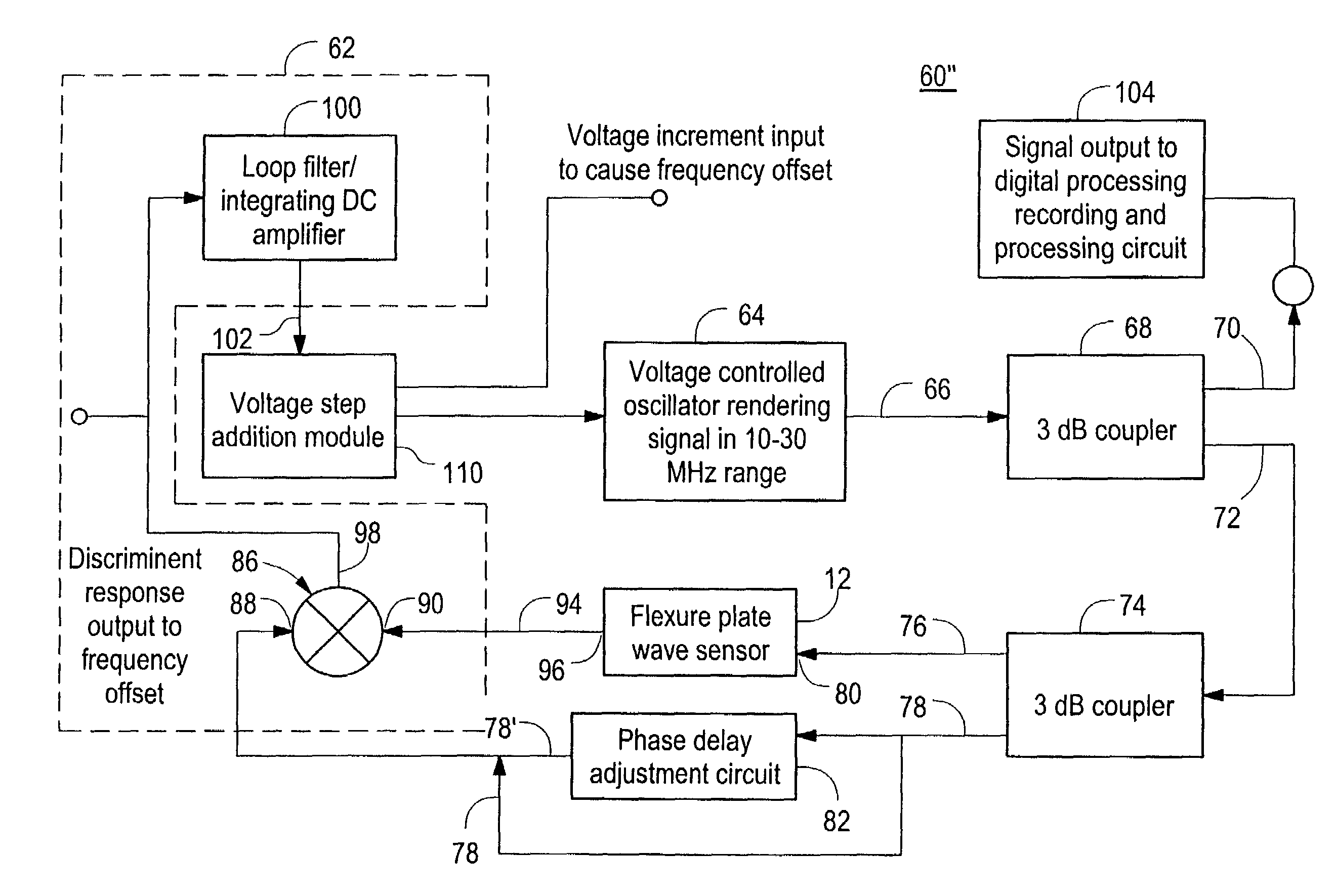

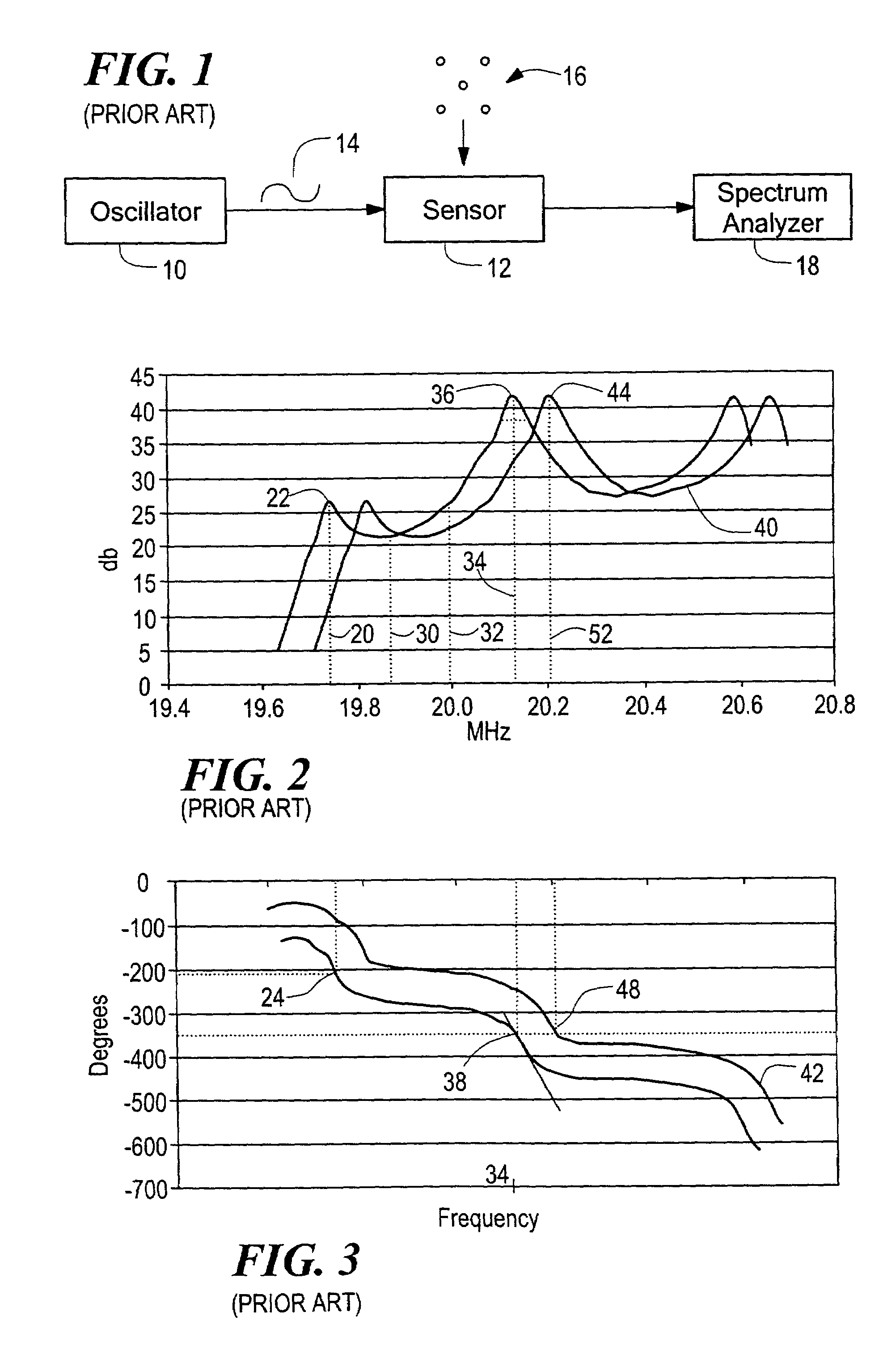

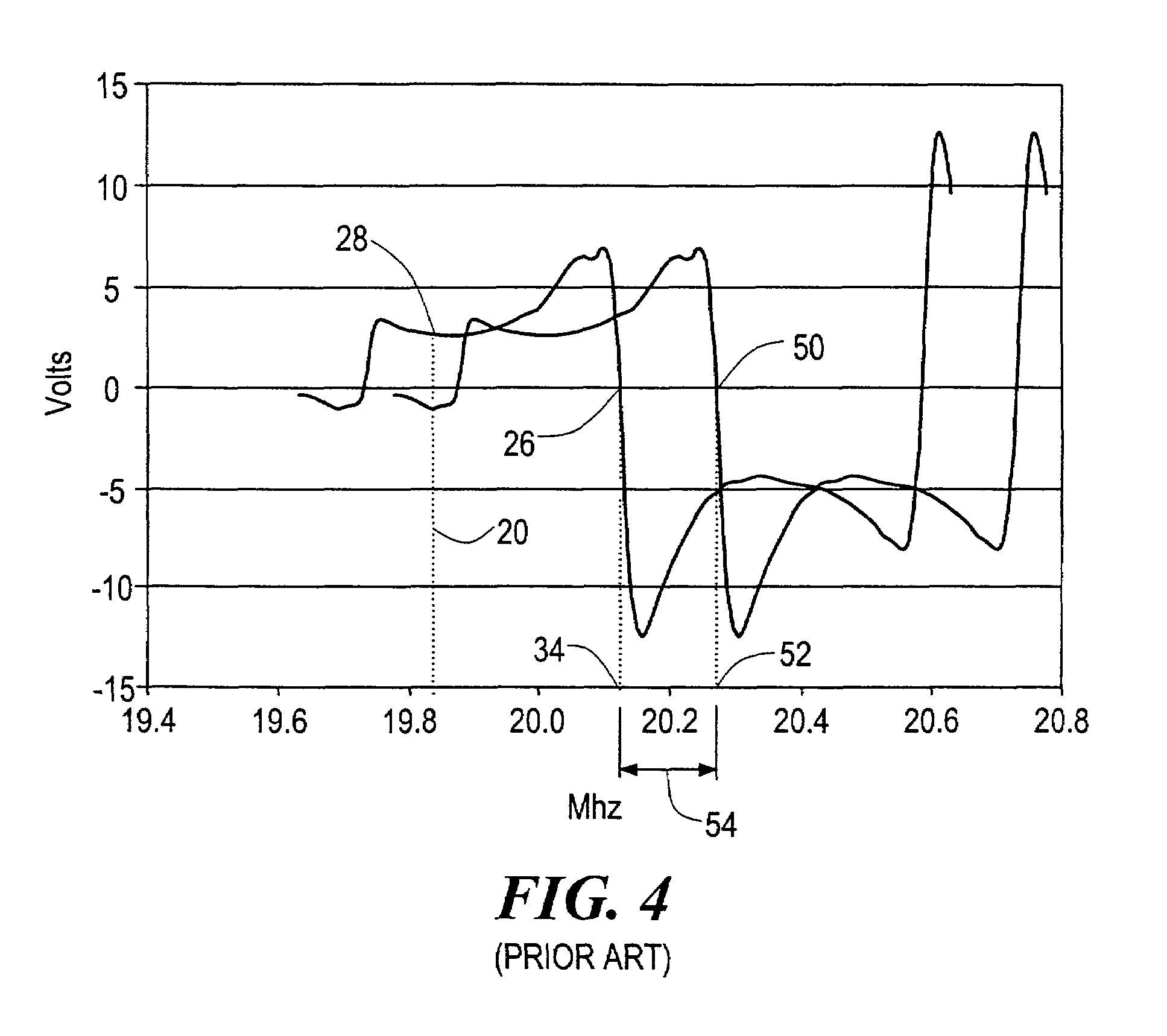

Sensor readout circuit

InactiveUS6972553B2Sure easyMaterial analysis using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersPhase detectorPhase difference

A sensor readout circuit which provides a frequency signal output including a phase detector circuit responsive to an output signal from a sensor and an input signal to the sensor and configured to detect the phase difference between the input signal and the output signal, and a drive circuit responsive to the phase detector circuit and configured to maintain a fixed phase difference between the input signal and the output signal.

Owner:CHARLES STARK DRAPER LABORATORY

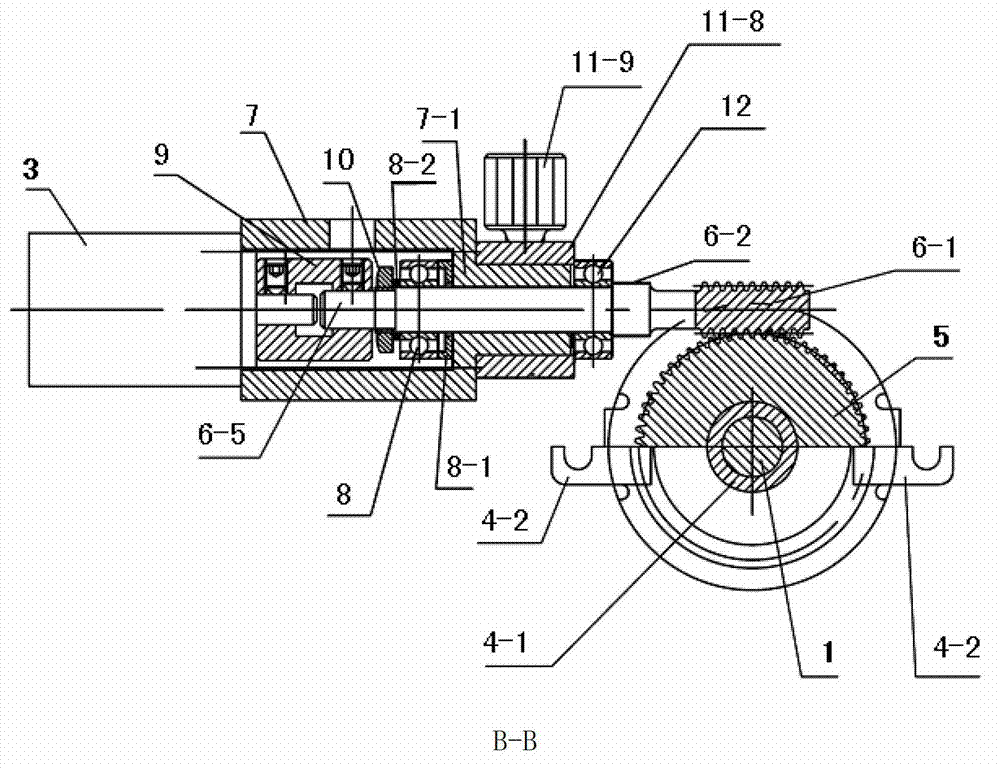

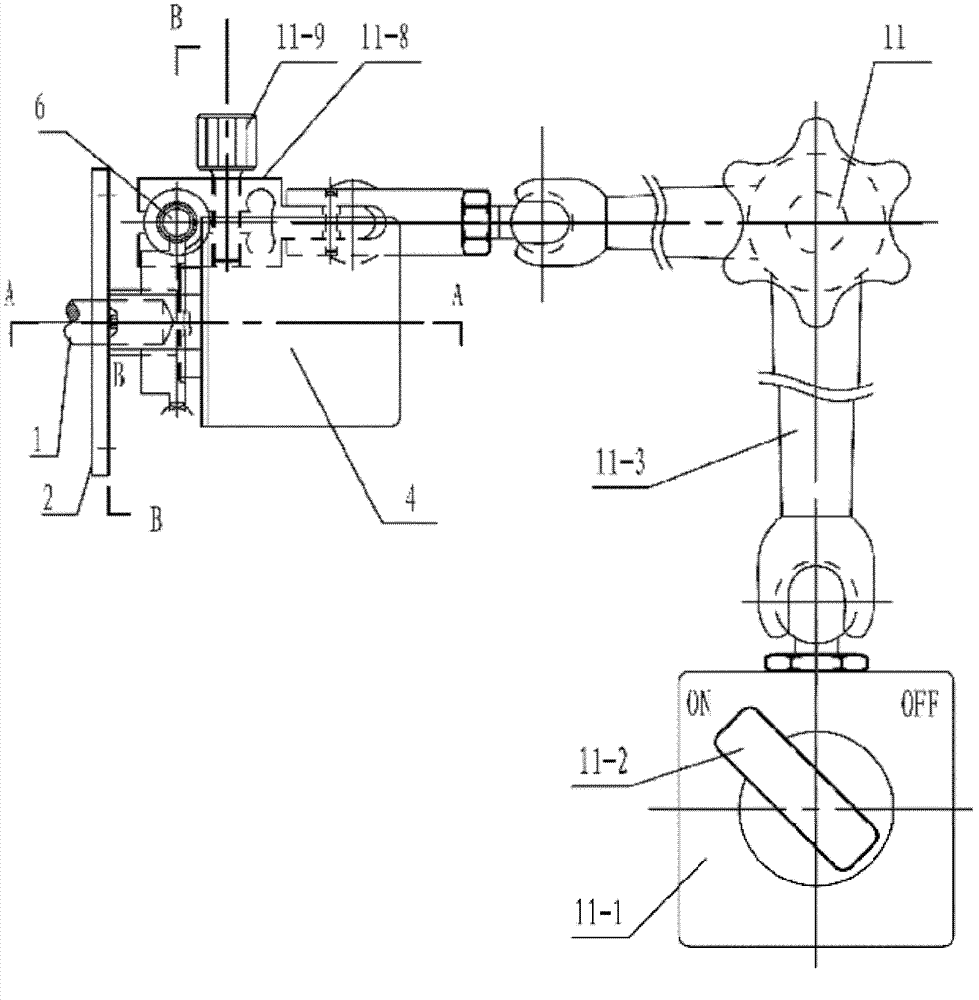

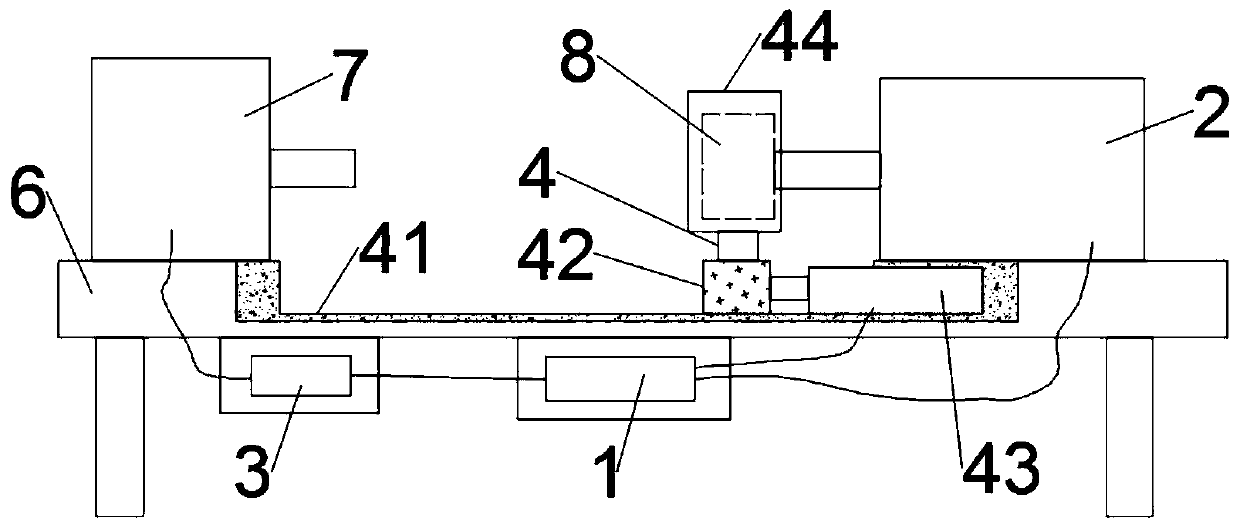

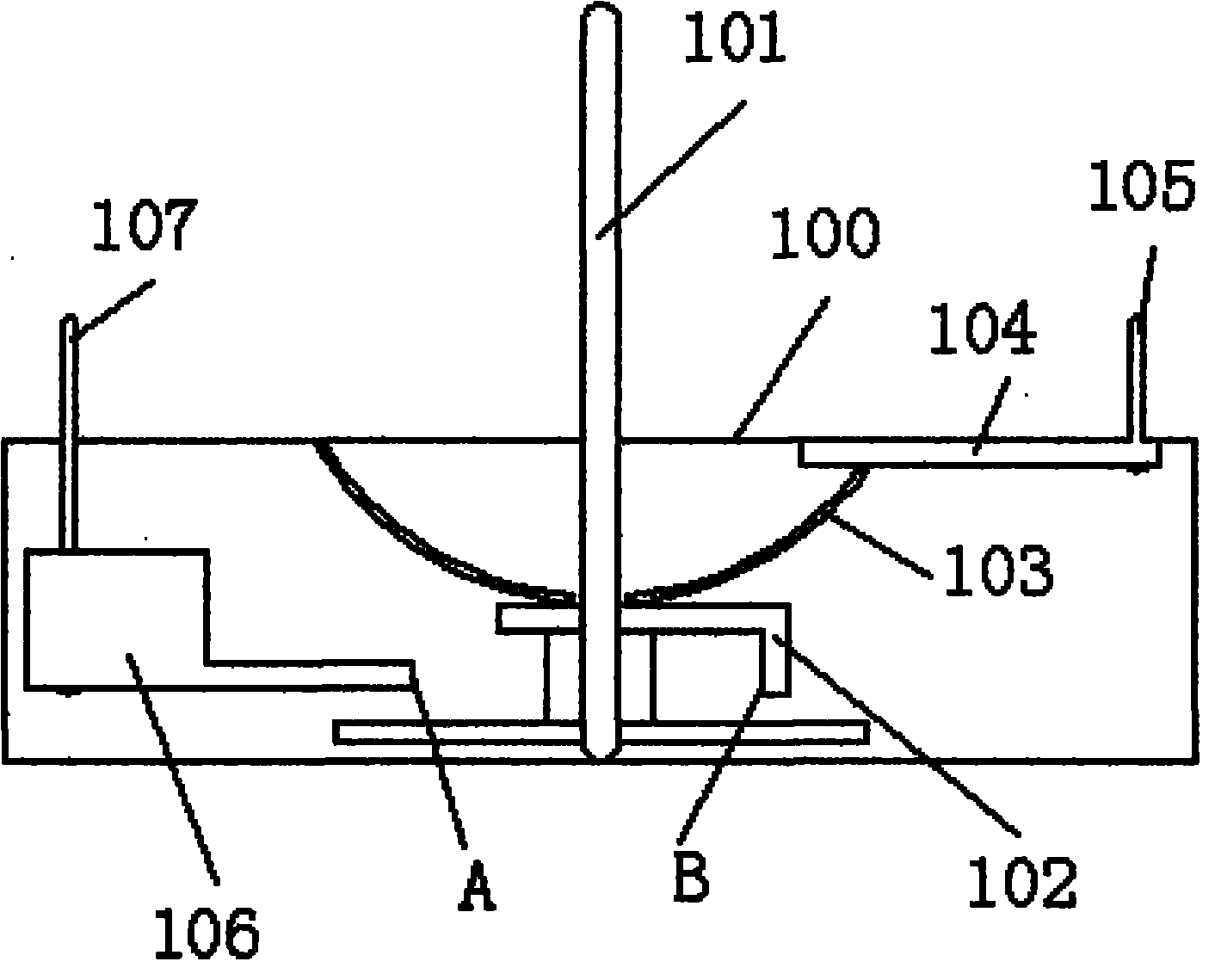

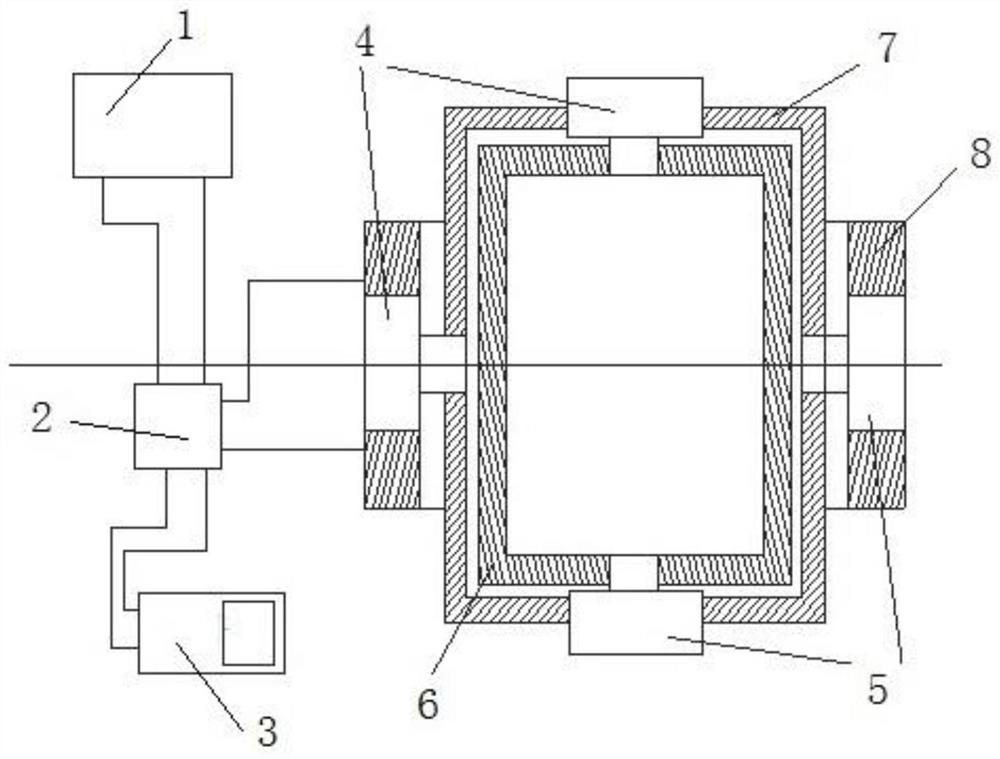

Zero adjustment device for rotary encoders and application method thereof

ActiveCN102853852AFirmly connectedEasy to connect and fixProvision for operation by null methodsAutomatic controlRotary encoder

The invention relates to a zero adjustment device for rotary encoders and an application method thereof. The device comprises an encoder acquisition card, a computer, an electronic hand wheel, a stepping motor driver, a stepping motor, a cylindrical worm, a helical gear and a universal magnetic gauge stand assembly, wherein the encoder acquisition card is used for connecting the signal output end of a rotary encoder of an automatic control mechanism, the computer is connected with the encoder acquisition card, the stepping motor driver is connected with output signals of the electronic hand wheel, and the stepping motor is connected with the stepper motor driver. In the process of operating, through rotating the electronic hand wheel, the stepping motor rotates and drives the helical gear to rotate through driving the cylindrical worm so as to drive a hollow rotating shaft, and meanwhile, the computer reads the output of the rotary encoder through the encoder acquisition card and displays whether the rotary encoder reaches a zero position; and when the rotary encoder reaches the zero position, a user stops rotating the electronic hand wheel, and the stepping motor stops rotating.

Owner:常州迈特运控电机有限公司

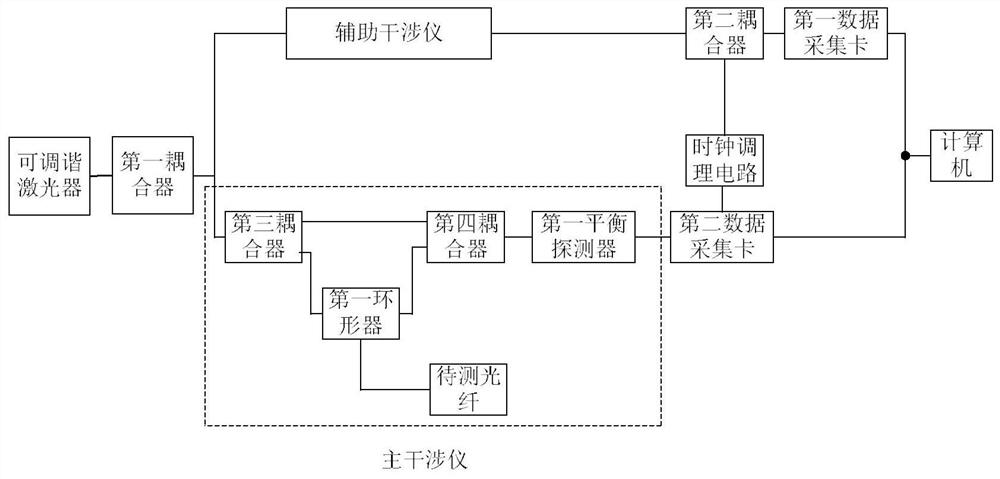

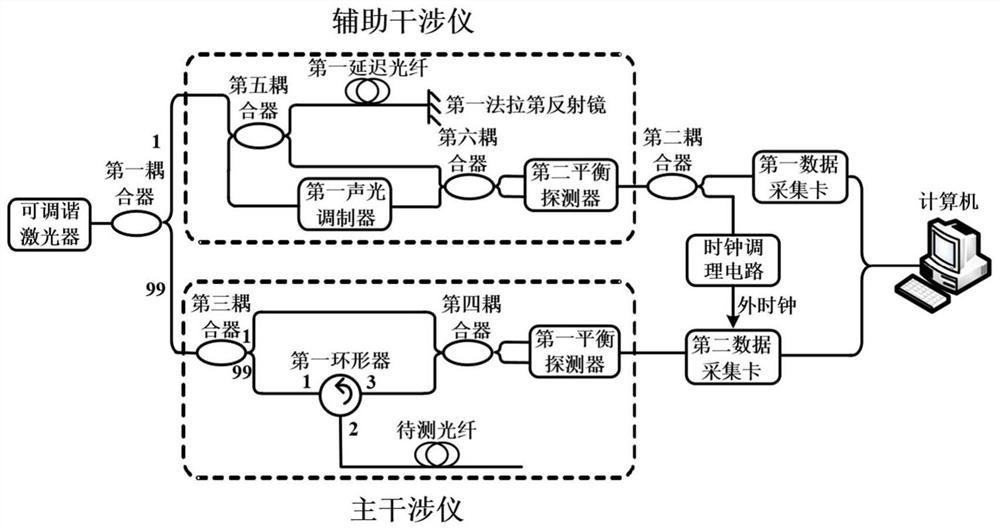

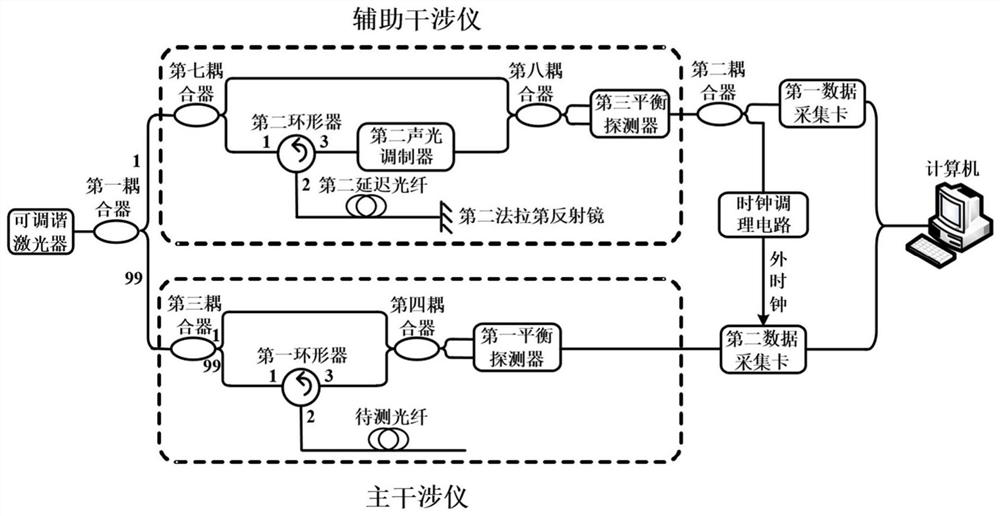

Optical fiber parameter measuring device for correcting nonlinear tuning effect

ActiveCN112923960AAvoid Polarization Fading PhenomenaImprove visibilityMitigation of undesired influencesProvision for operation by null methodsData acquisitionEngineering

The invention discloses an optical fiber parameter measuring device for correcting a nonlinear tuning effect. The device is characterized in that firstly, an acoustic optical modulator (AOM) is connected into an auxiliary interferometer of an OFDR and is used for carrying out frequency shift on light waves and increasing the frequency of a beat frequency signal; then the beat frequency signal is converted into an electric signal by a balance detector, the electric signal is divided into two circuits by an electric coupler, one signal is acquired by a data acquisition card with a high sampling rate, and the other signal is used as an external clock for signal acquisition of a main interferometer; and finally, the signal of the main interferometer is corrected through the simple data processing and by taking the signal zero crossing point of the auxiliary interferometer as a reference. According to the device, the high-precision measurement data can be obtained with lower cost, the redundant data volume is reduced, and the correction accuracy of nonlinear frequency sweeping of a laser in the OFDR and the operation speed of data processing can be improved at the same time.

Owner:NANJING UNIV

Motor controller, semiconductor integrated circuit, indicating instrument and method for controlling a motor

InactiveUS7129669B2Emergency protective circuit arrangementsSolid-state devicesControl signalMotor controller

A motor controller comprising, a detector configured to perform a difference processing for information relating to a counter electromotive force and an induced electromotive force generated by a stepping motor, and to generate a driving control signal based on a result of the difference processing, and a driver configured to drive the stepping motor based on the driving control signal.

Owner:KK TOSHIBA

One-key zero-returning device of transmitter

InactiveCN102135439AImplement migration adjustmentsAvoid replacementProvision for operation by null methodsKey pressingControl system

The invention discloses a one-key zero-returning device of a transmitter, which comprises a power module, a signal amplifying module, a key zero returning module, a voltage to current (V / I) conversion module, a calibration output module and a reference voltage module. By adoption of the one-key zero-returning device of the transmitter provided by the invention, adjustment of zero shift of any point of the transmitter can be realized effectively, a trouble on replacement and configuration of a new transmitter is avoided for a user, correction of the zero shift caused by long-time use of a sensor can be also realized at the same time, and convenience is provided for intellectualization of a control system.

Owner:单尼斯科(上海)仪器仪表有限公司

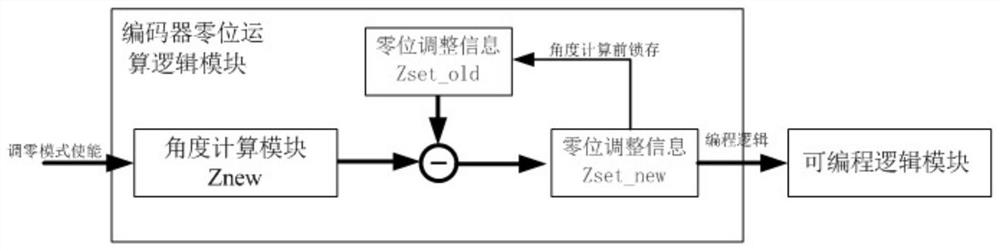

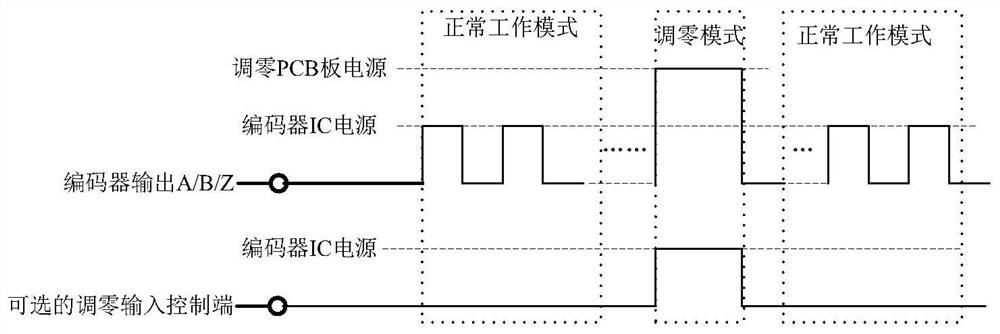

Method for zero setting of incremental encoder IC

ActiveCN111811544ARealize automatic zero adjustmentHighly integratedProvision for operation by null methodsProgramme control in sequence/logic controllersMultiplexingProgrammable logic device

The invention provides a method for zero setting of an incremental encoder IC, is used for solving problems of complex zero setting program and low efficiency in the prior art, and is composed of an input control module, a one-key zero setting multiplexing input control module, a one-key zero setting mode selection module, an encoder zero operation logic module, a programmable logic module, an incremental signal generation module, an output driving module and a zero setting PCB. Through application of the method, as long as a user installs the motor correctly, the interior of the encoder enters a one-key zero setting mode through an external zero setting control panel, an enabled one-key zero setting control input end or a multiplexed incremental output signal, zero setting information iscompared with an actual Z-phase zero position, logic operation is carried out, and the zero adjustment information is written into a programmable logic device, so automatic zero setting is realized.

Owner:赛卓微电子(深圳)有限公司

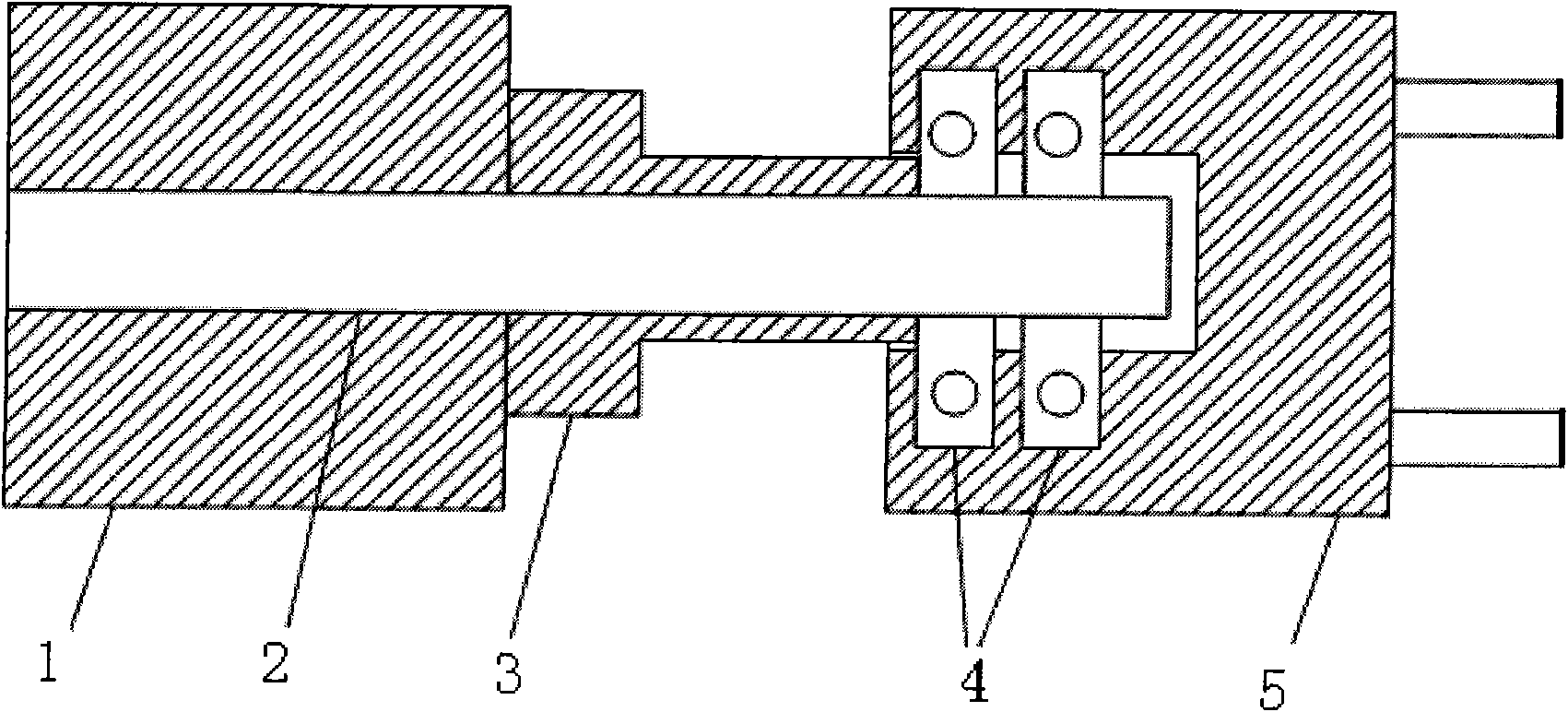

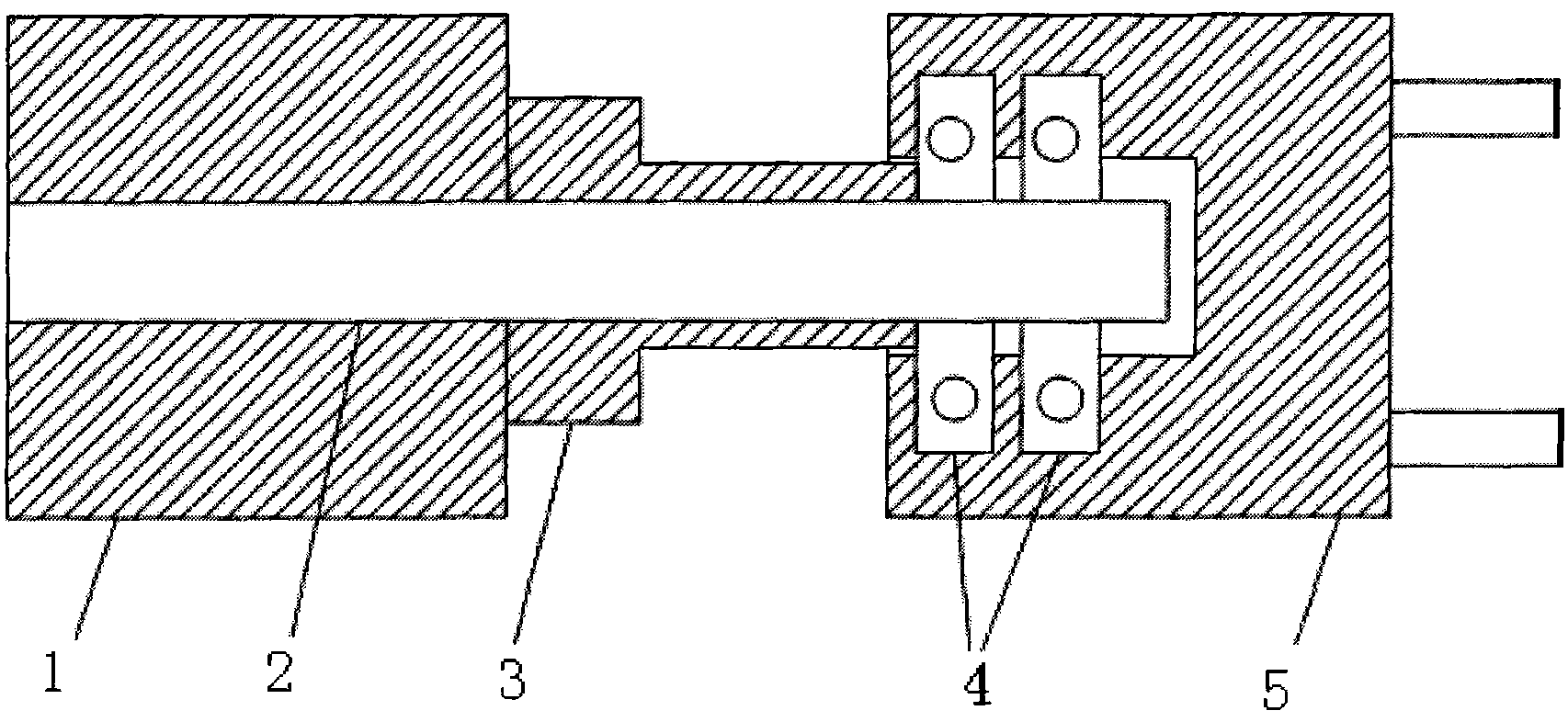

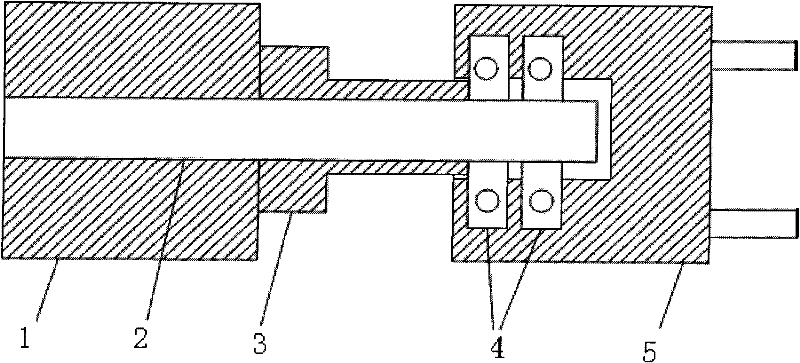

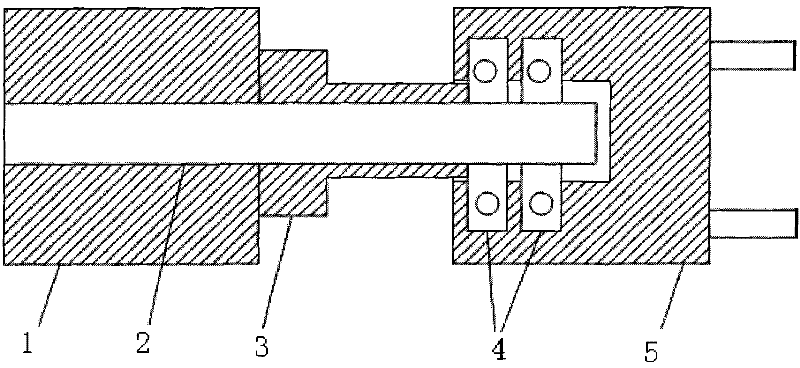

Zero-debugging method of sensor for main control valve of steering engine actuator

ActiveCN101915589AImprove assembly efficiencyImprove debugging efficiencyProvision for operation by null methodsActuatorControl valves

The invention belongs to a sensor debugging technique and relates to the improvement on a zero-debugging method of a sensor for a main control valve of a steering engine actuator. The zero-debugging method is used for carrying out mechanical zero debugging to a sensor [5] and comprises the following steps of: adjusting a gap between a flexible rod [2] and a sensor bush [3]; measuring the change amounts of four-channel output values of the sensor [5]; and adjusting the angle of the sensor bush [3]. The zero-debugging method can solve the problem of the ultra-poor consistency of the four-channel output values of the sensor after the main control valve is installed on the steering engine actuator and improve the assembling and debugging efficiency of the steering engine actuator.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

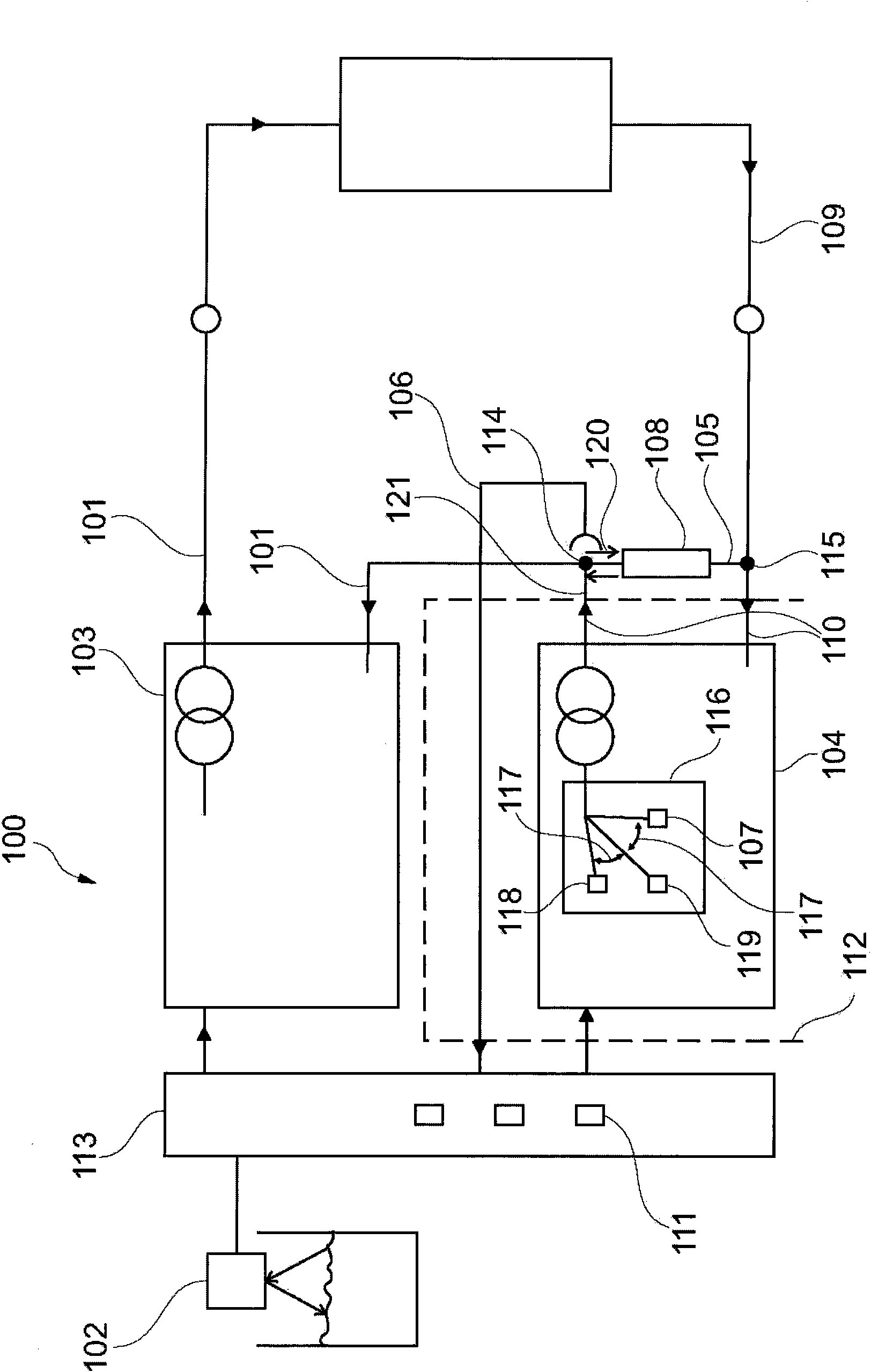

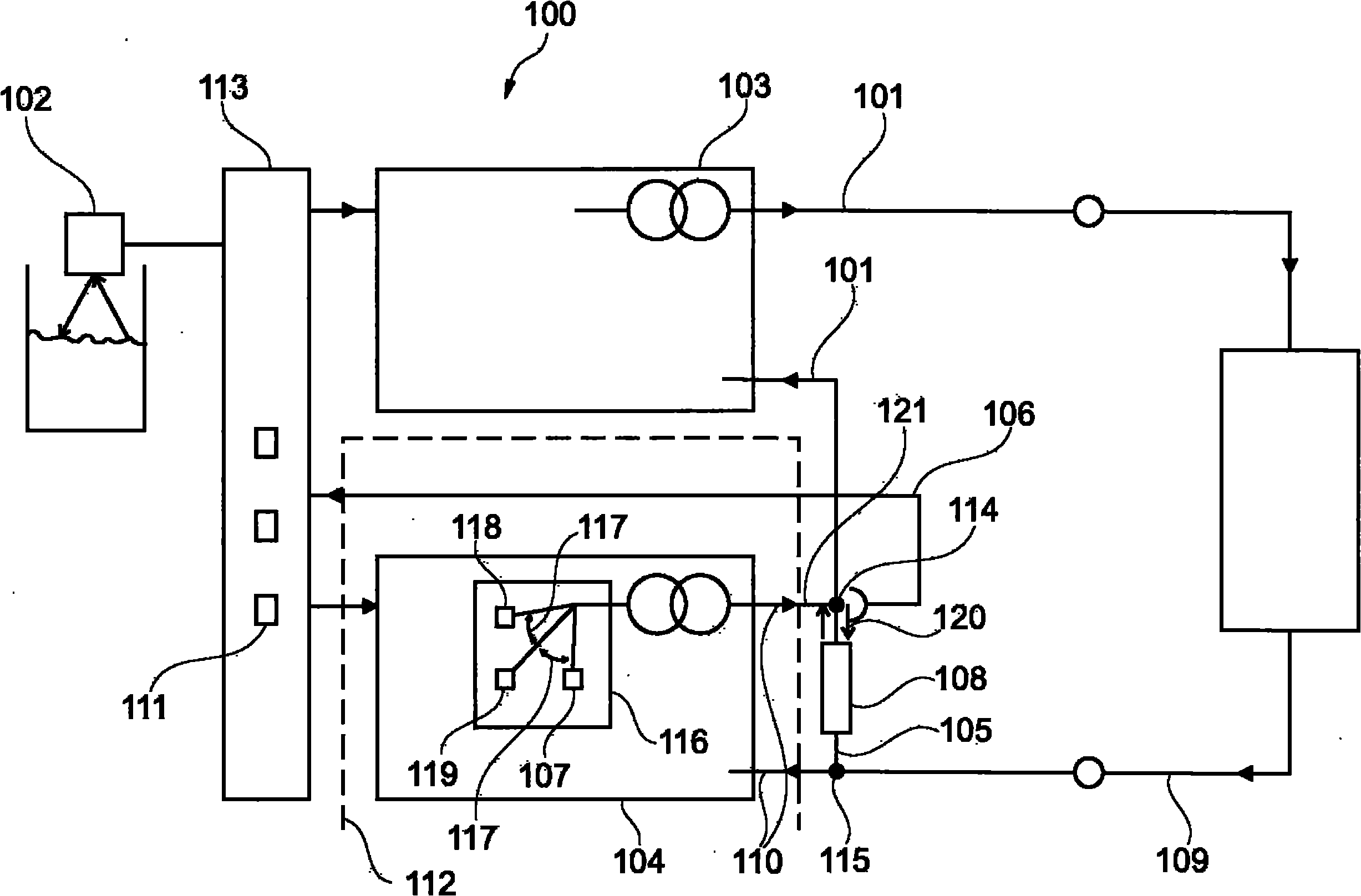

Energy production device for producing and simultaneously monitoring measured current

ActiveCN101806823ACurrent/voltage measurementProvision for operation by null methodsEngineeringSpecific time

The generation and monitoring of a load-independent output current for a level meter, pressure gauge, flowmeter or evaluation device are described. A current that is equal or unequal to the measuring current, but inverted relative thereto, can be generated continuously or within certain time intervals in a switching circuit that is realized independently of the network generating the measuring current. The generated current can be fed into the measuring circuit at a comparison point and added. The compensation principle makes it possible to determine whether the measuring current corresponds to the nominal value, wherein a testing current is fed into the first electric circuit by means of a second switching circuit that contains a second current source. A certain expectancy value of a voltage to be tapped can be calculated in dependence on the testing current being fed in and the nominal value. If the measured voltage deviates from the expectancy value, a deviation of the measuring current from the nominal value is detected and can be output for a user.

Owner:VEGA GRIESHABER GMBH & CO

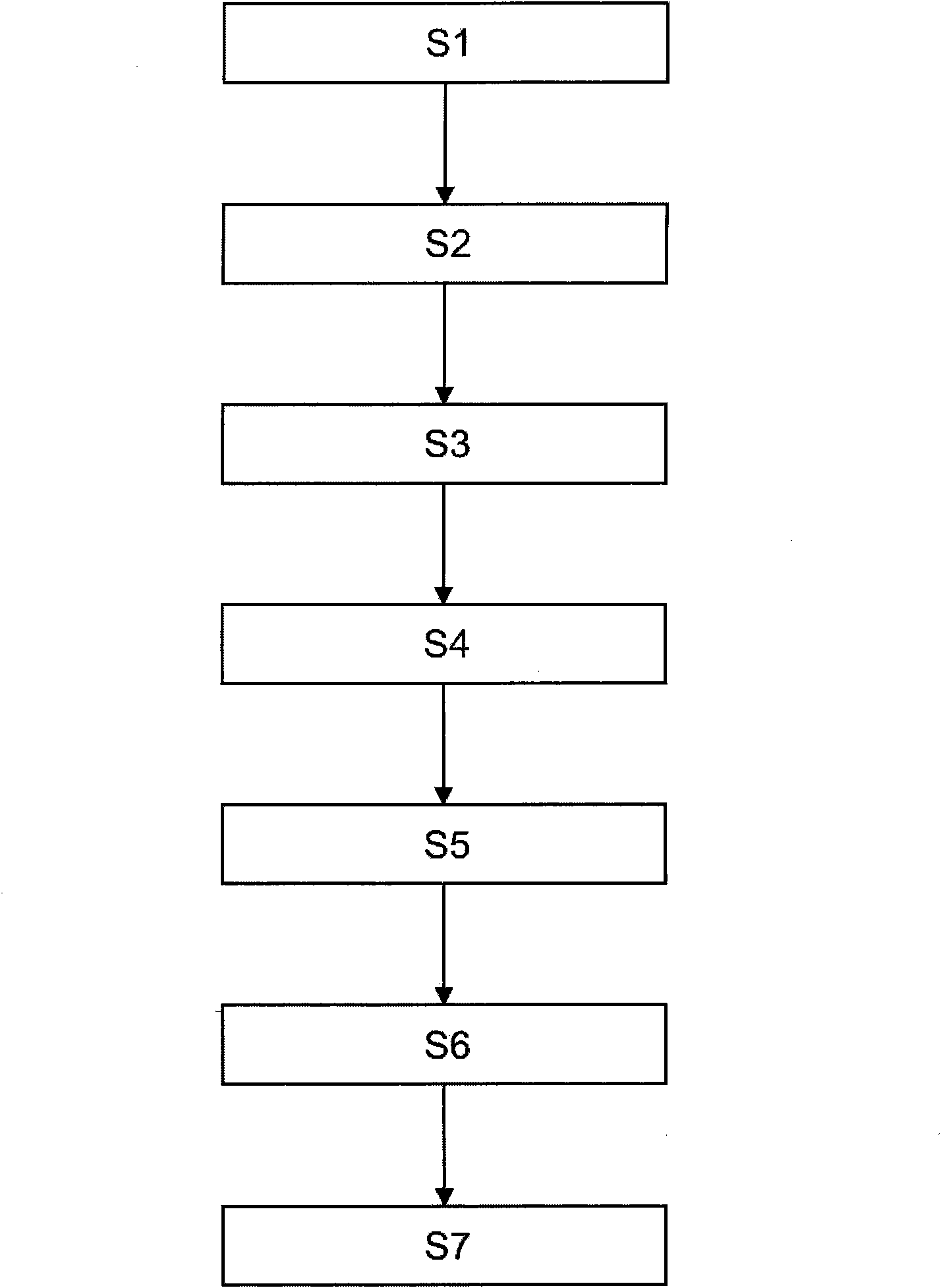

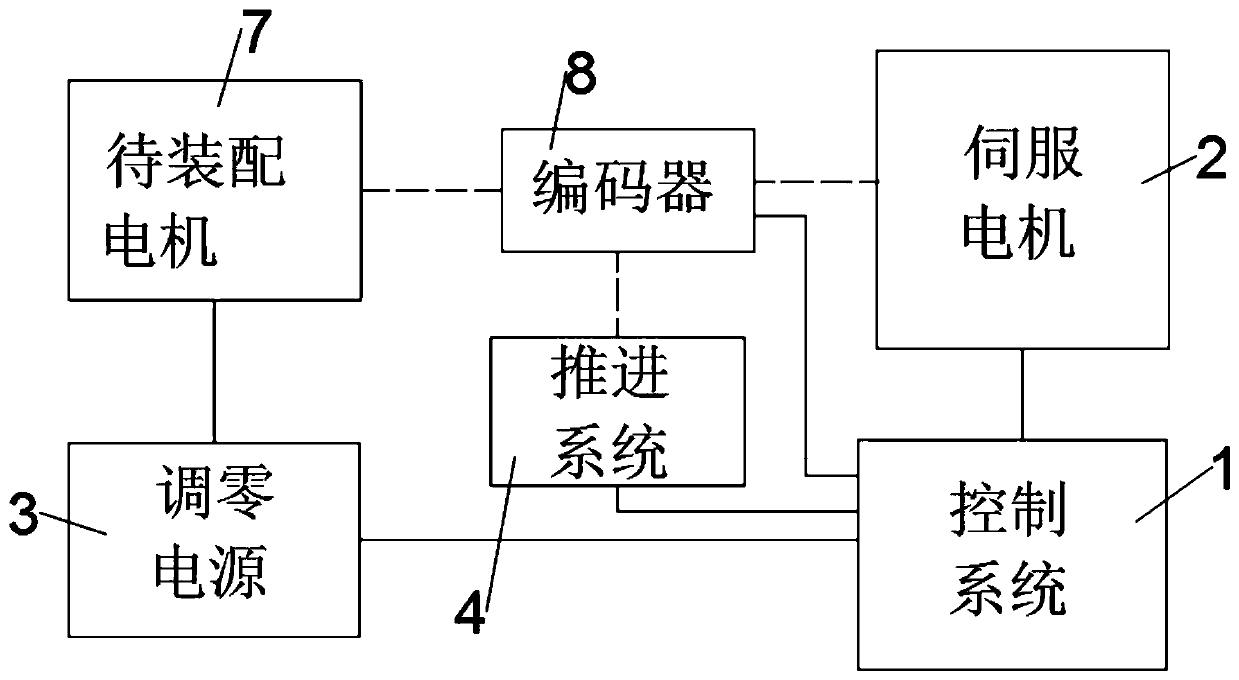

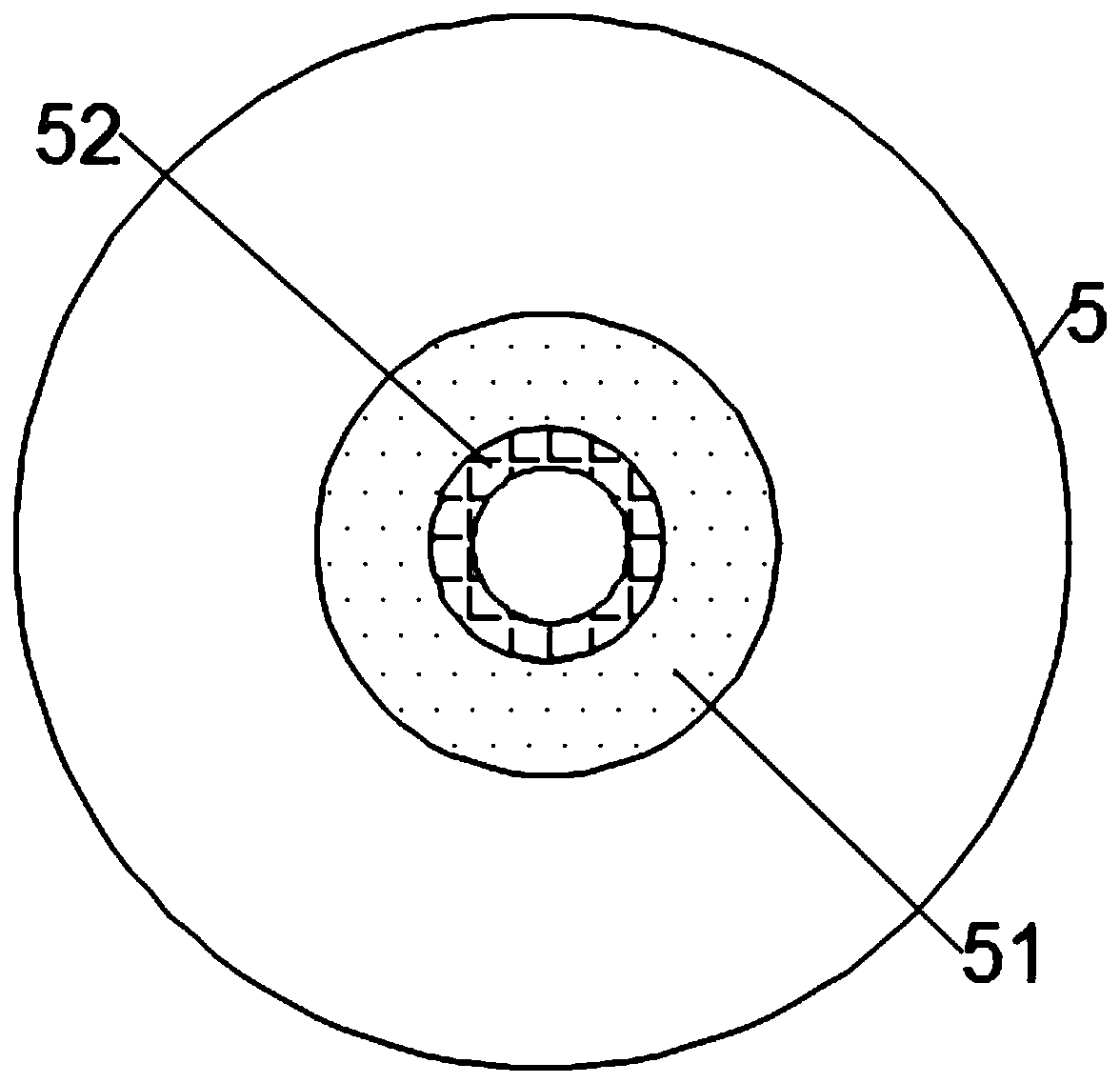

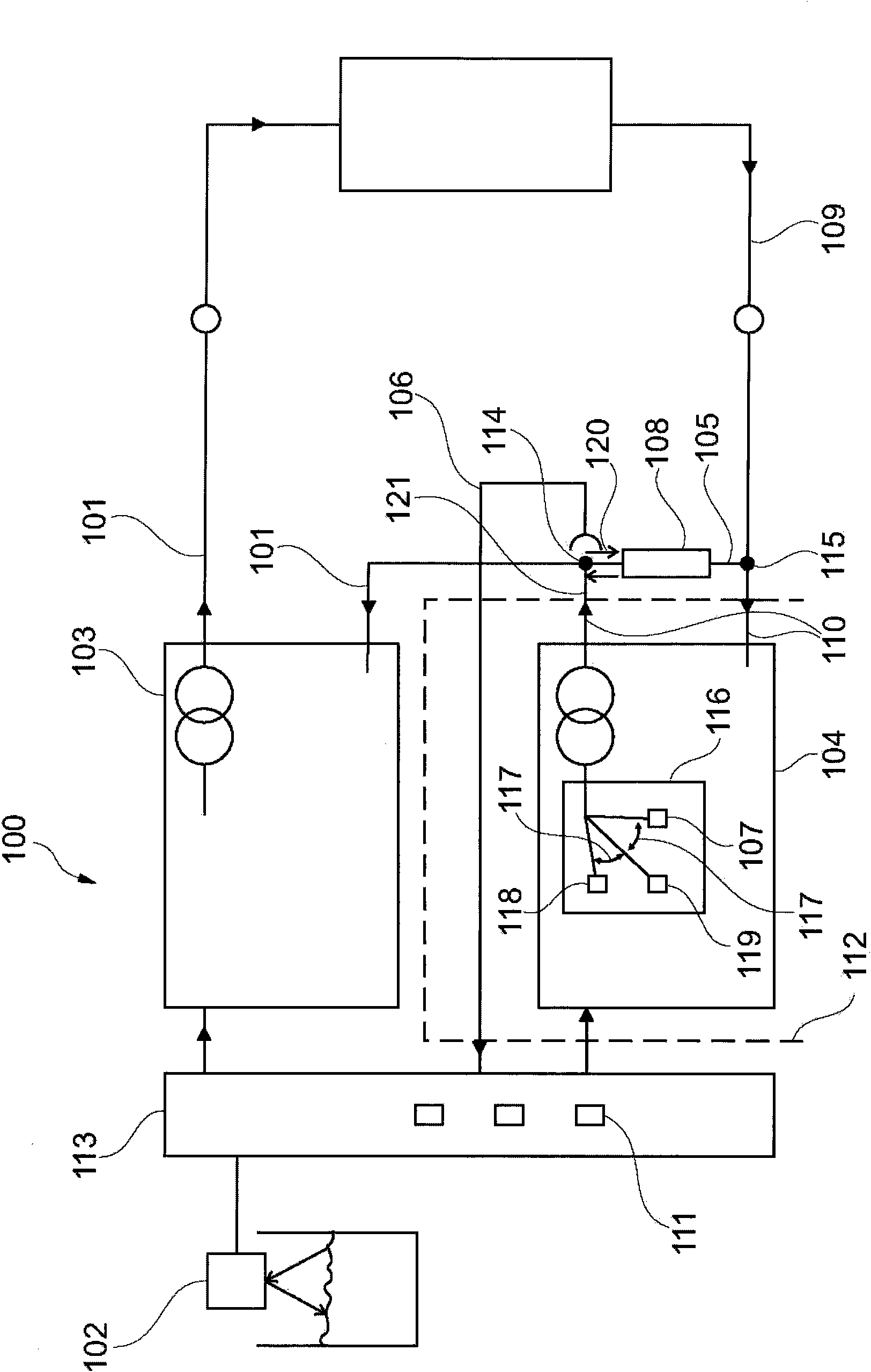

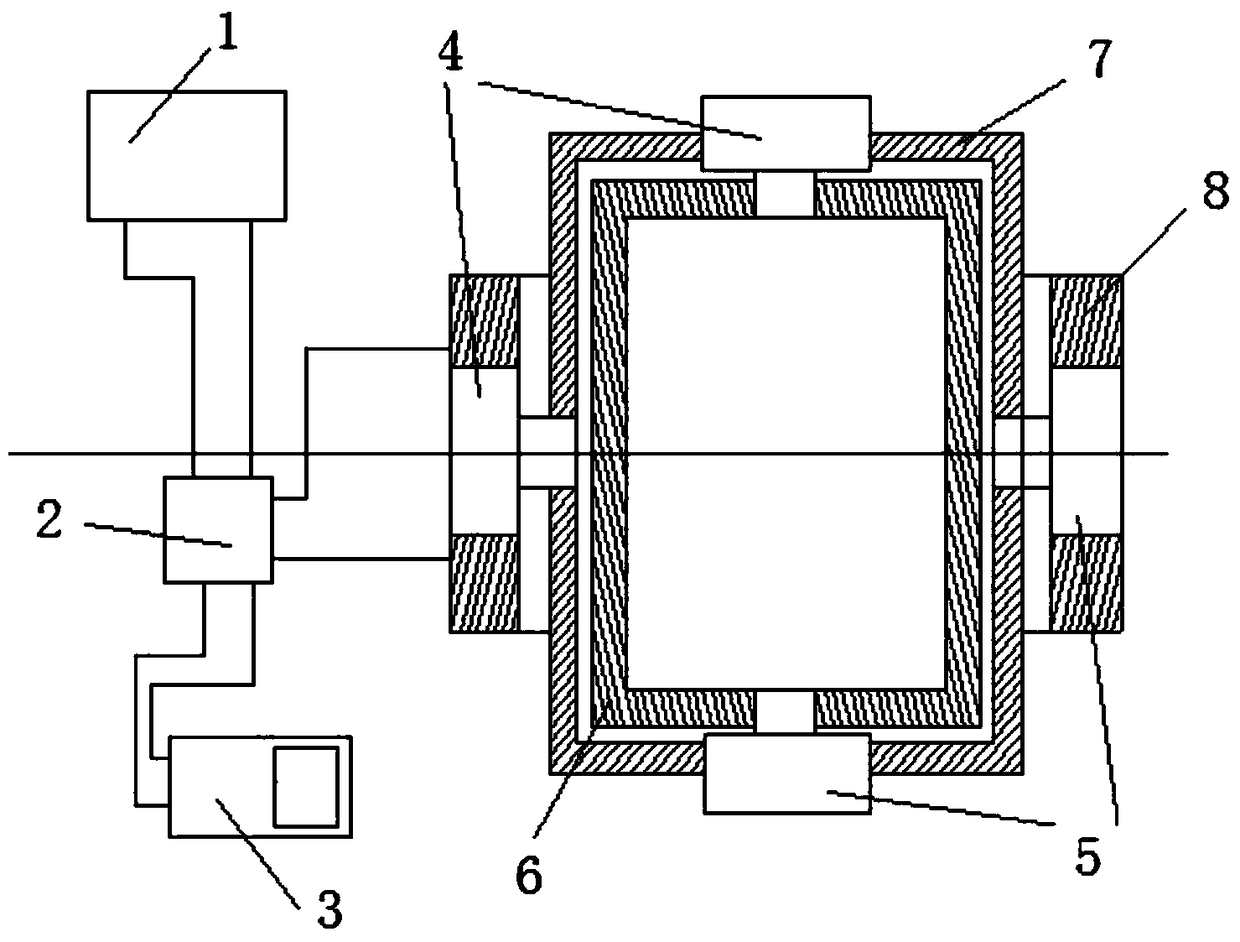

Automatic zero setting system and zero setting assembly method for encoder

InactiveCN110631608AReduce matching timeSave time on manual zeroingProvision for operation by null methodsControl systemElectric machinery

The embodiments of the invention disclose an automatic zero setting system and zero setting assembly method for an encoder. The automatic zero setting system comprises a control system, a servo motor,a zero setting power source and a propulsion system; the control system controls the servo motor to perform zero setting on the encoder; the zero setting power source supplies power to an to-be-assembled motor; the control system controls the propulsion system to assemble the encoder on the to-be-assembled motor; the propulsion system controls the encoder to be connected with the servo motor; thecontrol system controls the servo motor to perform zero setting on the encoder; the control system controls the zero setting power source to send out a zero setting power supply signal to the to-be-assembled motor so as to perform zero setting; after the encoder and the to-be-assembled motor are both zeroed, the propulsion system automatically connects the encoder with the to-be-assembled motor;and finally an encoder shell is manually fixed. Thus, manual zero setting time is saved; and zero setting is performed through the control system, and therefore, zero setting precision and efficiencyare high.

Owner:SHANGHAI POWERMAX TECH INC

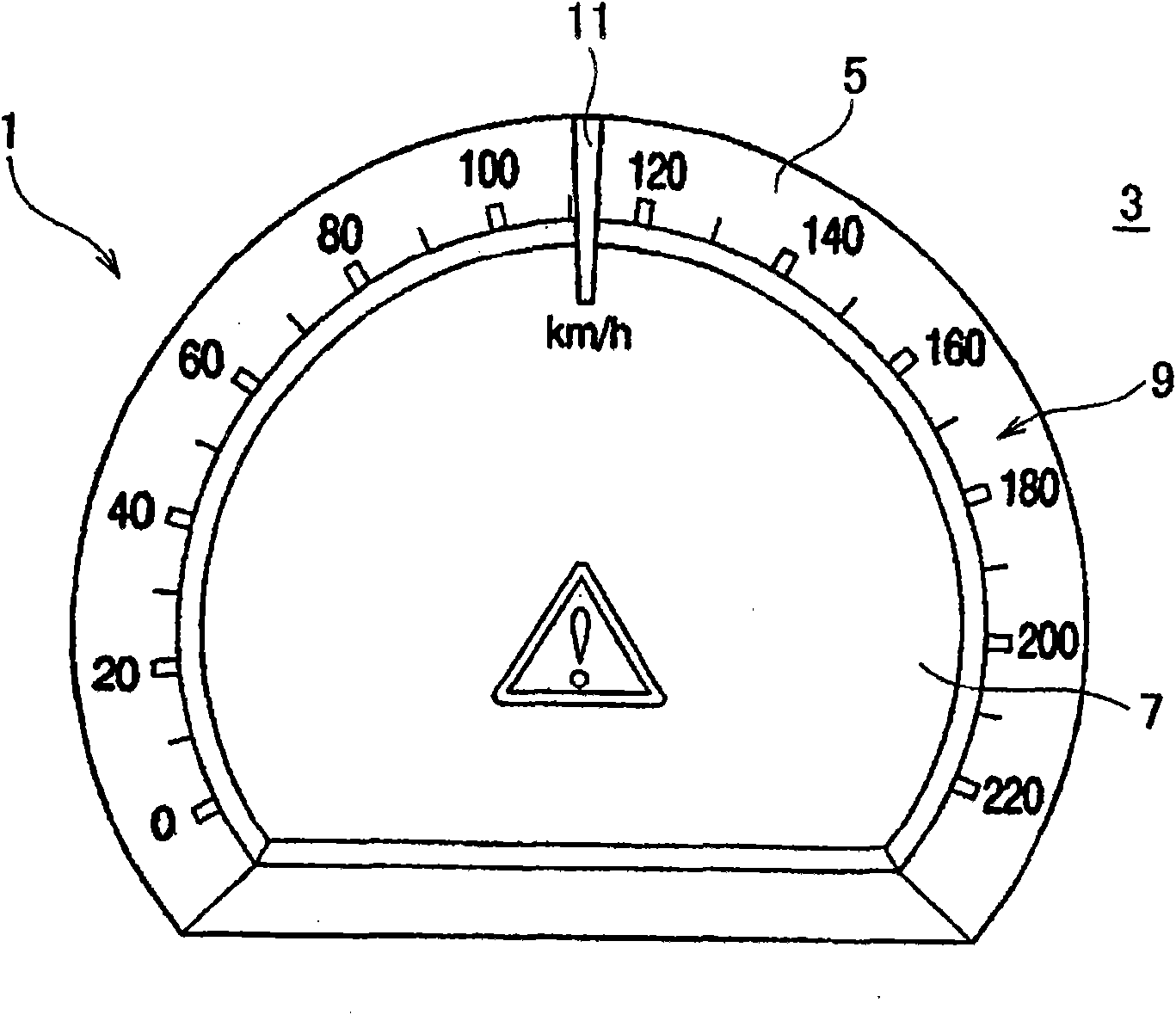

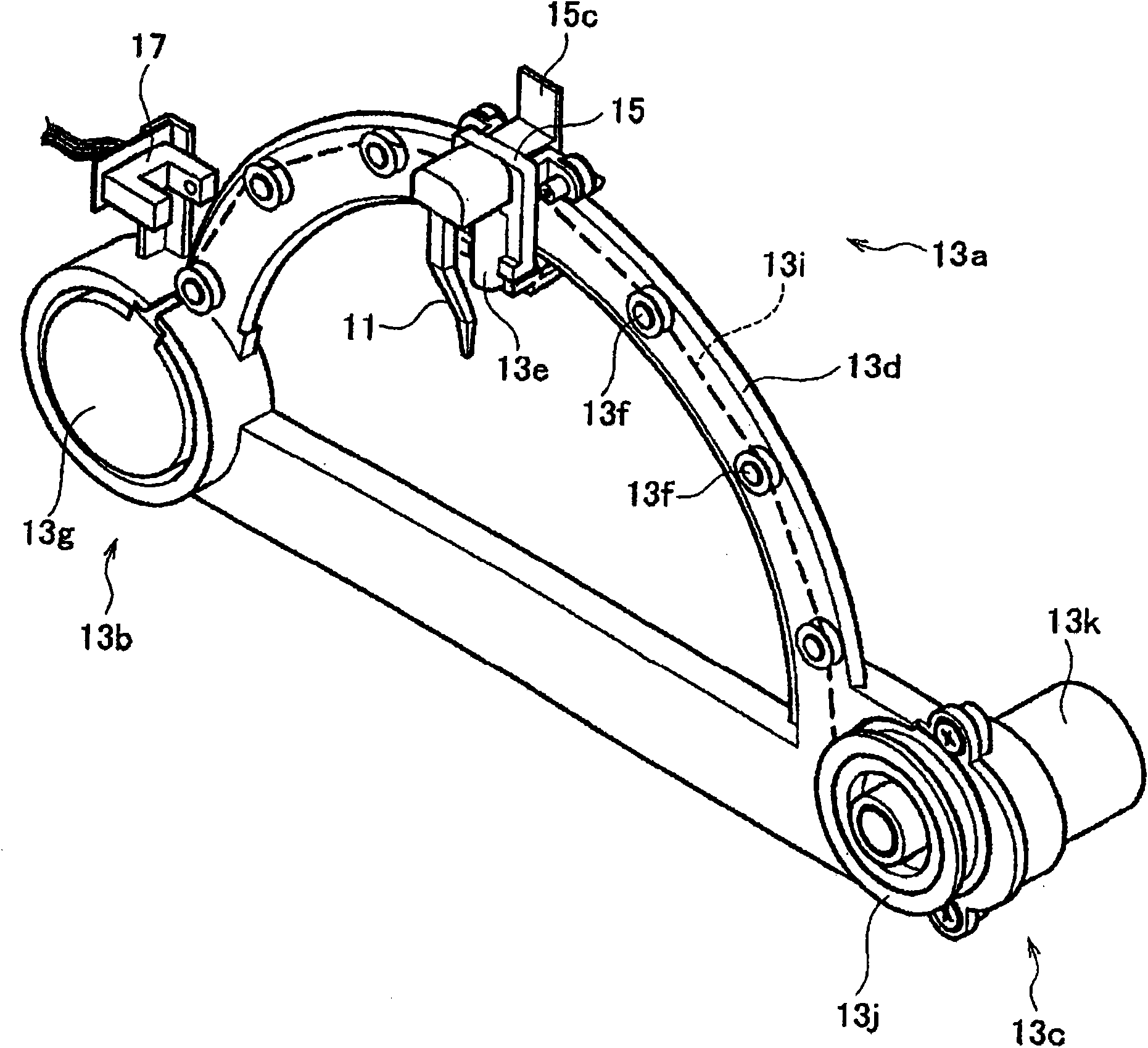

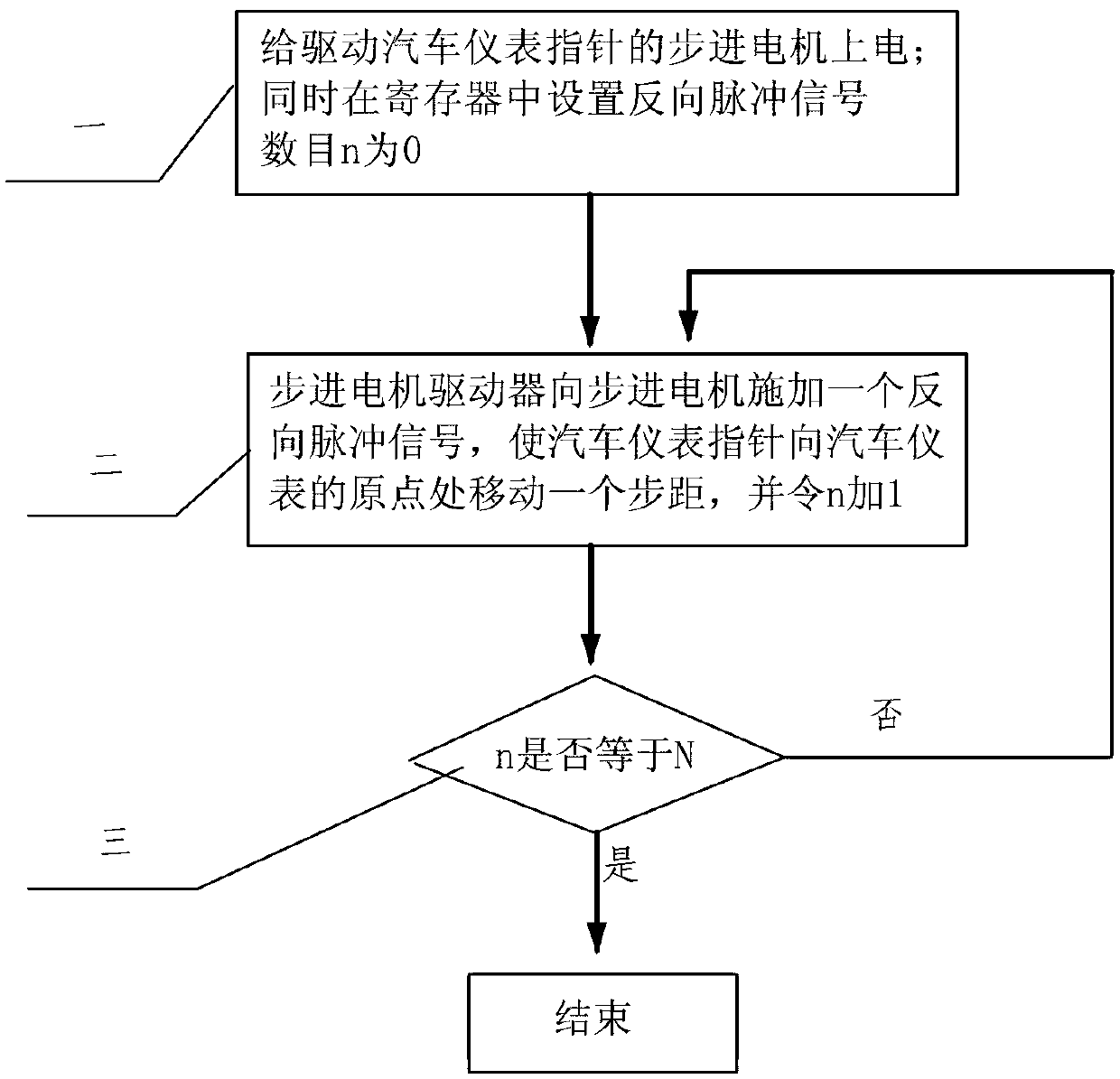

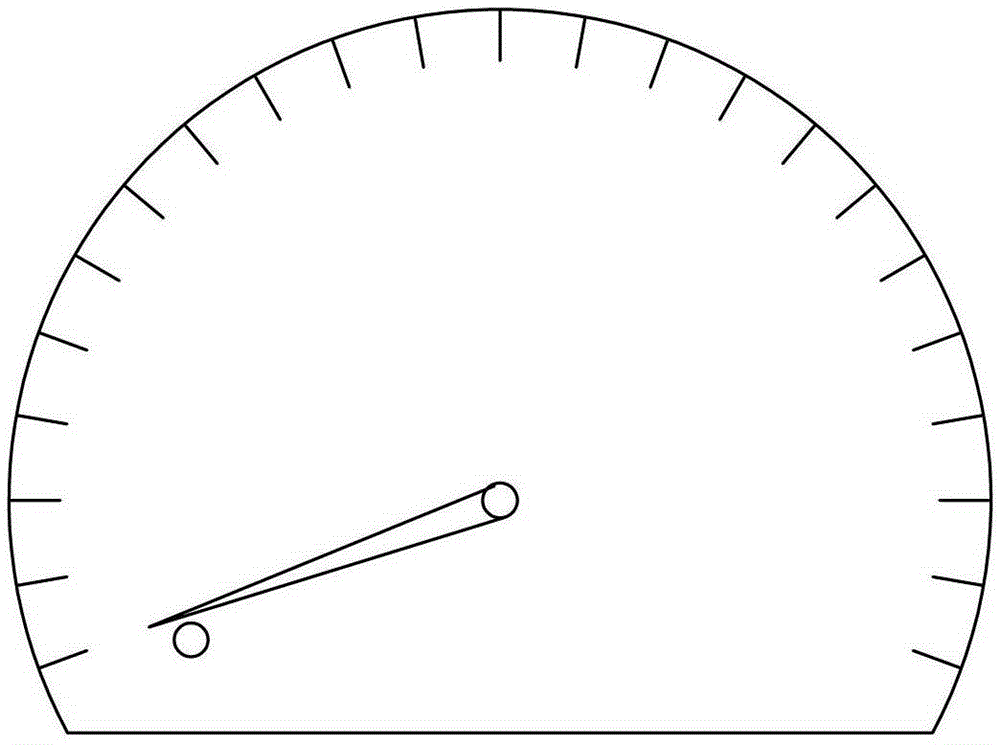

Method of returning pointer to origin point

ActiveCN101858756APointer movementOK to moveMeasurement apparatus componentsIndication apparatusSimulationTime based

There is provided a method of returning a pointer driven by a motor to an origin point disposed between a starting point and an endpoint of a movement range of the pointer, the method comprising the steps of: moving the pointer from an arbitrary point in the movement range to a reference point that is away from the starting point by not less than a distance between the starting point and the origin point; thereafter moving the pointer from the reference point toward the starting point; detecting the pointer by a sensor at a detection point whose relative position with respect to the origin point is known; and stopping, when the pointer at the detection point is detected, the pointer moving from the reference point toward the starting point at a predetermined point of time based on timing of the detection of the pointer at the detection point.

Owner:YAZAKI CORP

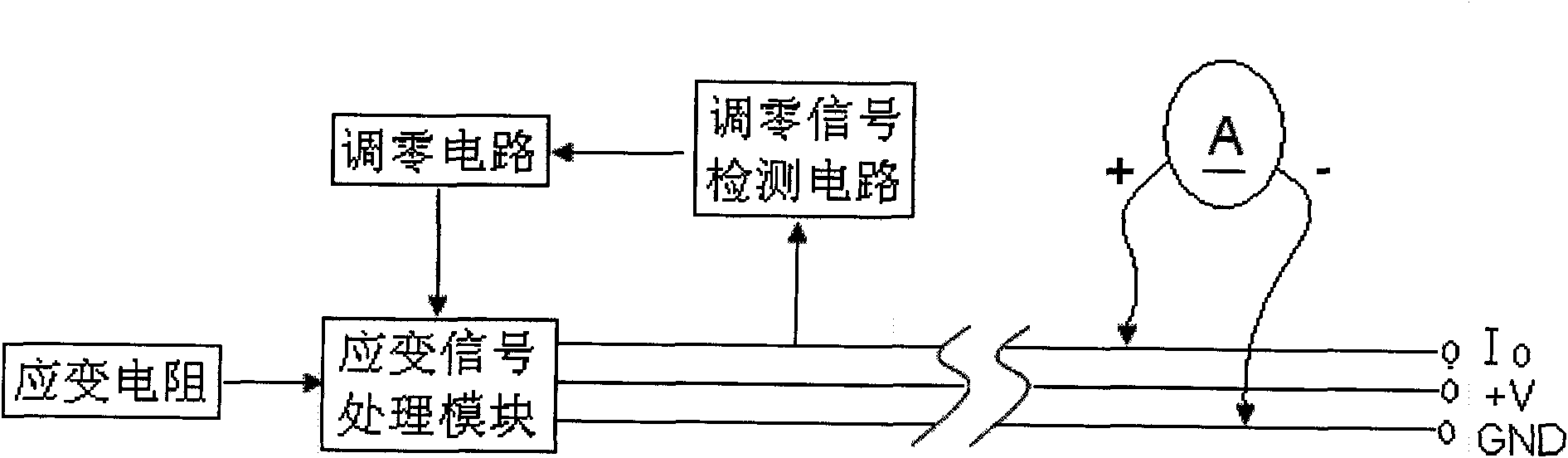

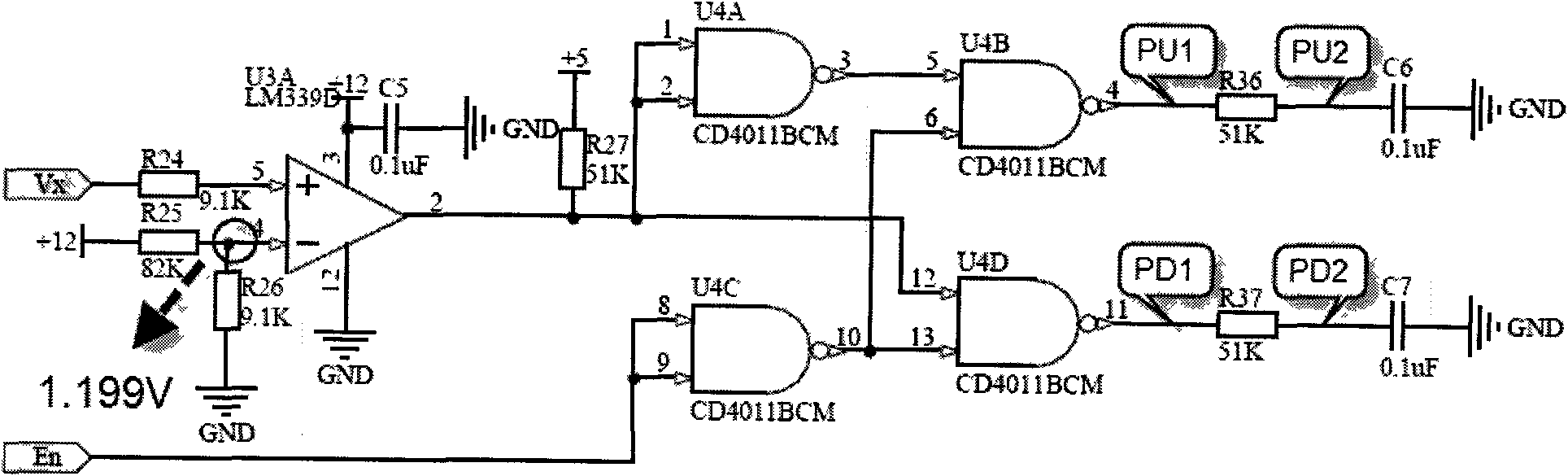

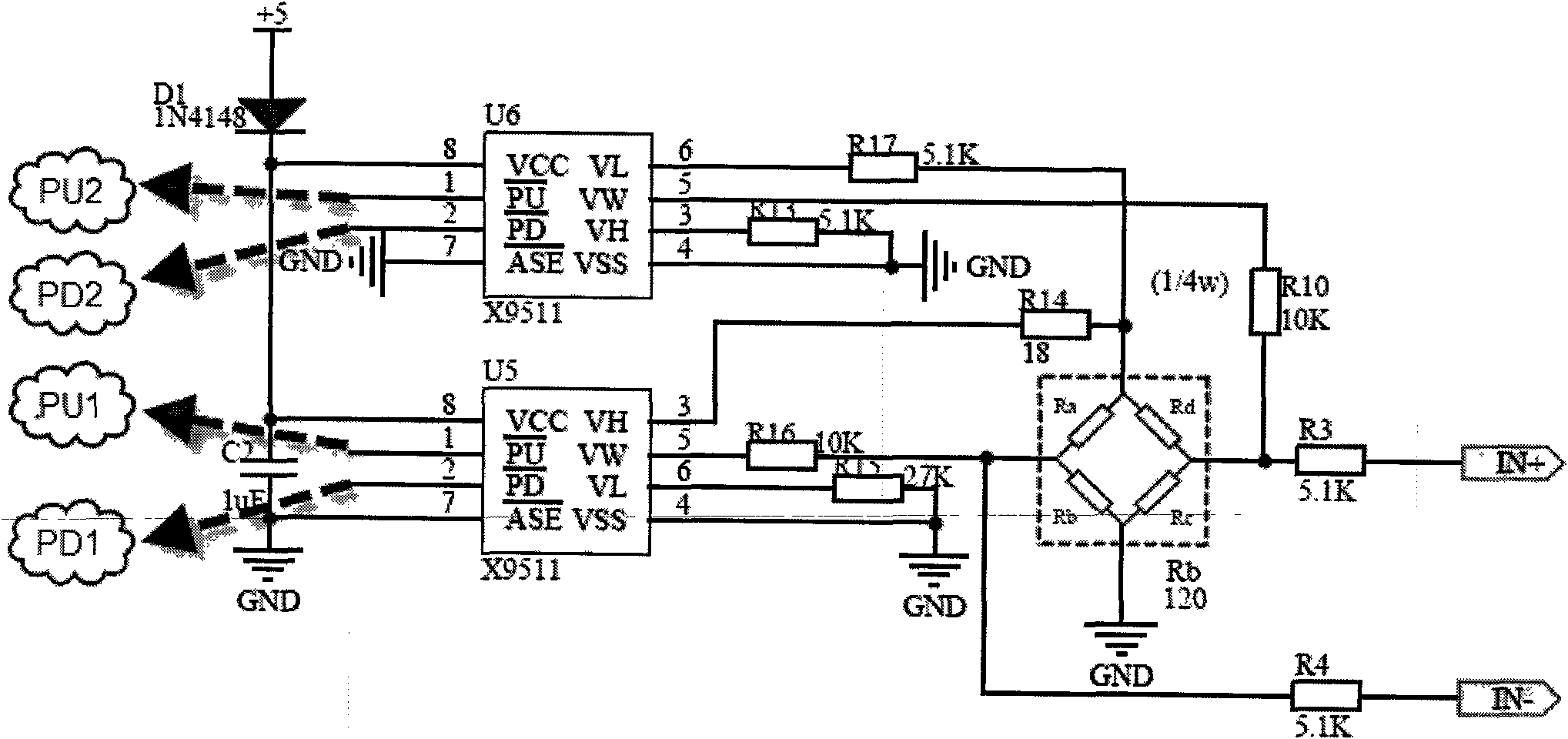

Remote zero setting circuit and method for resistance-type strain measurement

ActiveCN102087119ASolve the problem of difficult zero adjustmentThe zero adjustment method is simple and practicalProvision for operation by null methodsControl roomStrain sensor

The invention discloses a remote zero setting circuit and a remote zero setting method for resistance-type strain measurement. The functions of the zero setting circuit are realized by operating a strain sensor, a zero setting signal detection circuit and the zero setting circuit together; the zero setting signal detection circuit monitors the signal state of an output current signal line constantly; and if the zero setting signal detection circuit detects that the current signal line and the ground are short circuited, the enabling of the zero setting signal is valid, and the zero setting circuit starts to work to realize the zero setting function of the resistance-type strain measurement. In the remote zero setting method for the resistance-type strain measurement, additional zero setting signal lines are not needed in the whole zero setting process; the zero setting method is simple and practical; staff do not need to go to the installation field of the sensor and the zero setting function of the sensor can be realized in a control room; and circuit parameters after the zero is set can be automatically stored and are not lost after interruption of power supply. The remote zero setting circuit for the resistance-type strain measurement solves the problems of great difficulty in zero setting of a resistance-type strain sensor, consumes low power and is low in cost, easy to operate, and convenient to popularize and use.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

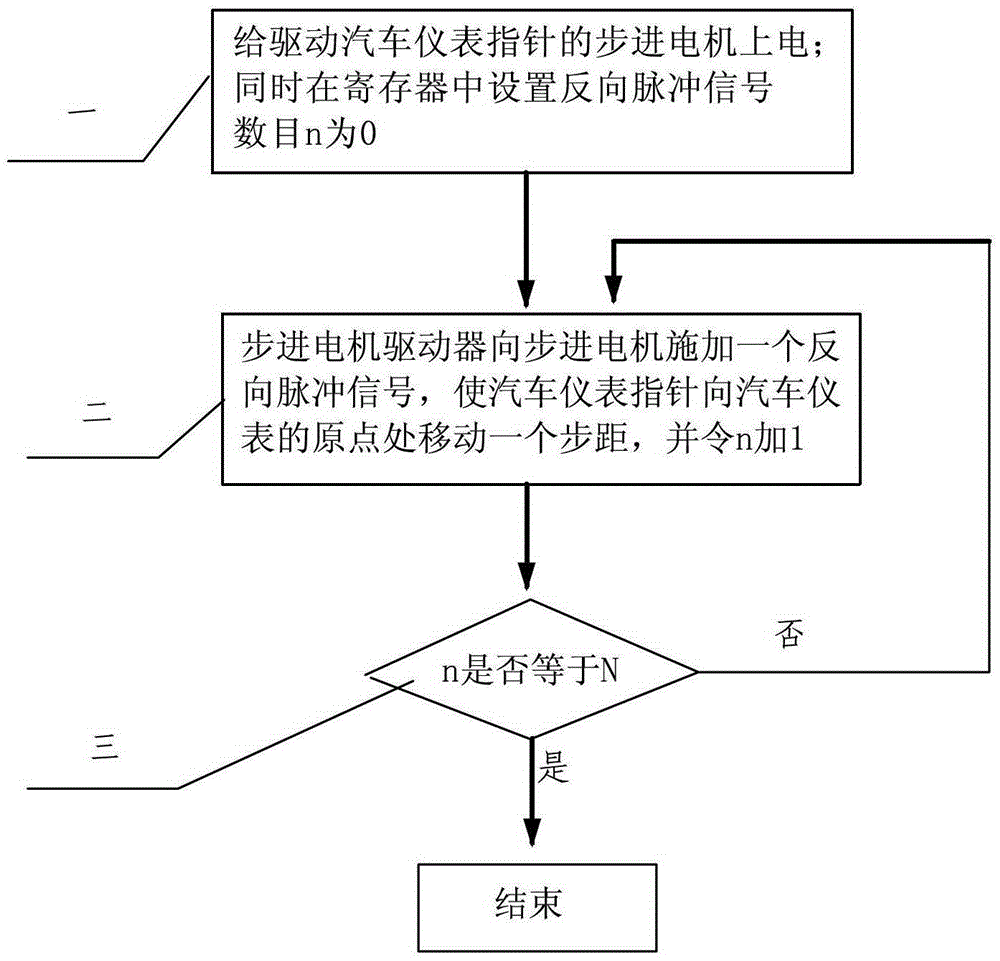

Method for enabling automobile meter needle to point zero through inertia

ActiveCN103344261ANo added complexityAvoid bouncing actionProvision for operation by null methodsMicrocontrollerMicrocomputer

The invention relates to a method for enabling an automobile meter needle to point zero through inertia. The method aims to solve the problem that in an existing mode for enabling an automobile meter needle to return to the original point, a hardware circuit is added. The method comprises the following steps of (1) electrifying a stepping motor driving the automobile meter needle and setting the number n of reverse pulse signals in a register to be 0, (2) exerting a reverse pulse signal to the stepping motor through a stepping motor driver to enable the automobile meter needle to move a step towards the original point of the automobile meter needle and enabling n to be 1, (3) judging if the number n of the reverse pulse signals exerted to the stepping motor by the stepping motor driver is equal to N through a single chip microcomputer, and (4) executing the step (2) if the result of the step (3) is 'no', and ending the steps if the result of the step (3) is 'yes'.

Owner:AEROSPACE HI TECH HLDG GROUP

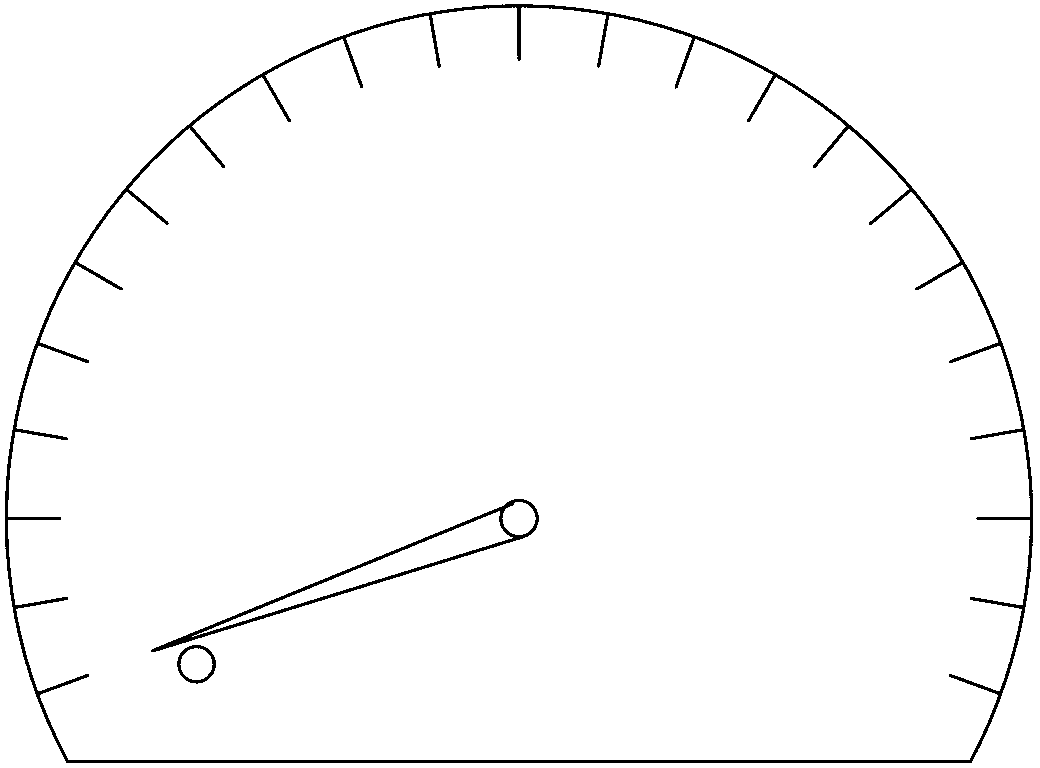

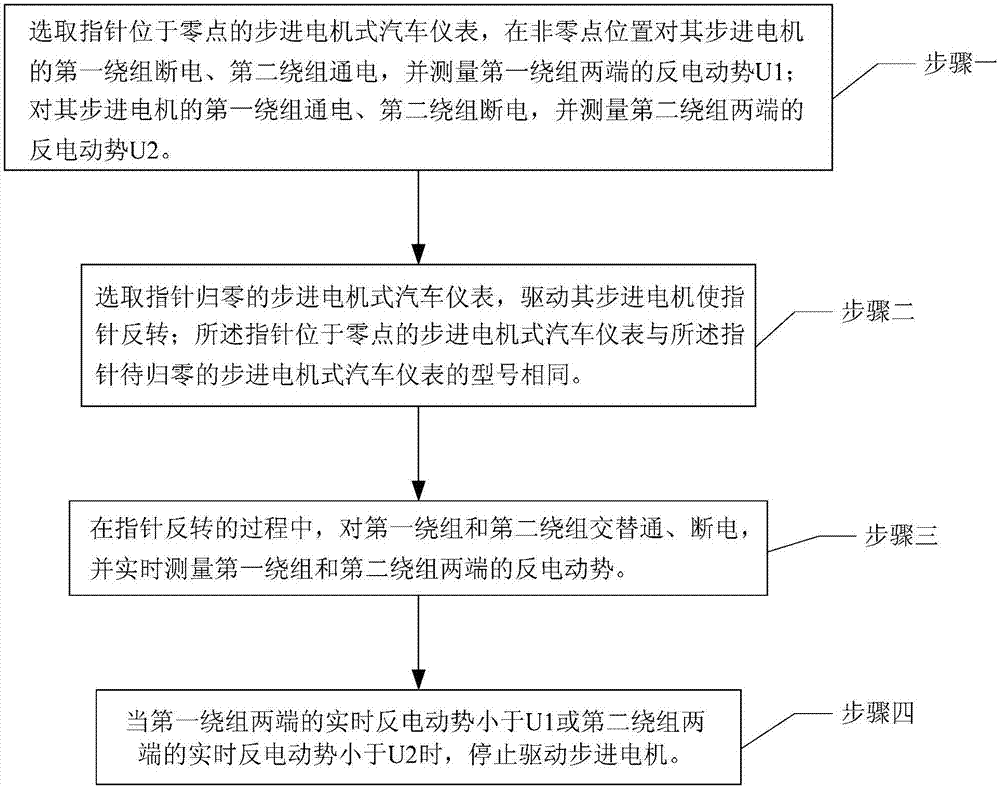

Stepping motor automobile instrument pointer return-to-zero method based on counter electromotive force measurement

InactiveCN107101652AAchieve precise zeroingReduce jitterElectric motor controlDynamo-electric converter controlReturn-to-zeroEngineering

The present invention provides a stepping motor automobile instrument pointer return-to-zero method based on counter electromotive force measurement, and belongs to the automobile instrument field. The problem is solved that a current stepping motor automobile instrument pointer return-to-zero method has high noise, big pointer jittering and large occupation control resource. The method performs alternative switching on or off of the first winding and the second winding of a stepping motor in the back drive return-to-zero process of the stepping motor automobile instrument pointer. In the back drive return-to-zero process, the counter electromotive forces of two ends of an outage winding are big. When the stepping motor automobile instrument pointer reaches zero, the counter electromotive forces of two ends of the outage winding are rapidly decreased. The method performs real-time measurement mode of the counter electromotive forces of two ends of the outage winding in the back drive return-to-zero process of the stepping motor automobile instrument pointer to realize the accurate return-to-zero of the stepping motor automobile instrument pointer. The stepping motor automobile instrument pointer return-to-zero method based on the counter electromotive force measurement is configured to perform return-to-zero of the stepping motor automobile instrument pointer.

Owner:AEROSPACE HI TECH HLDG GROUP

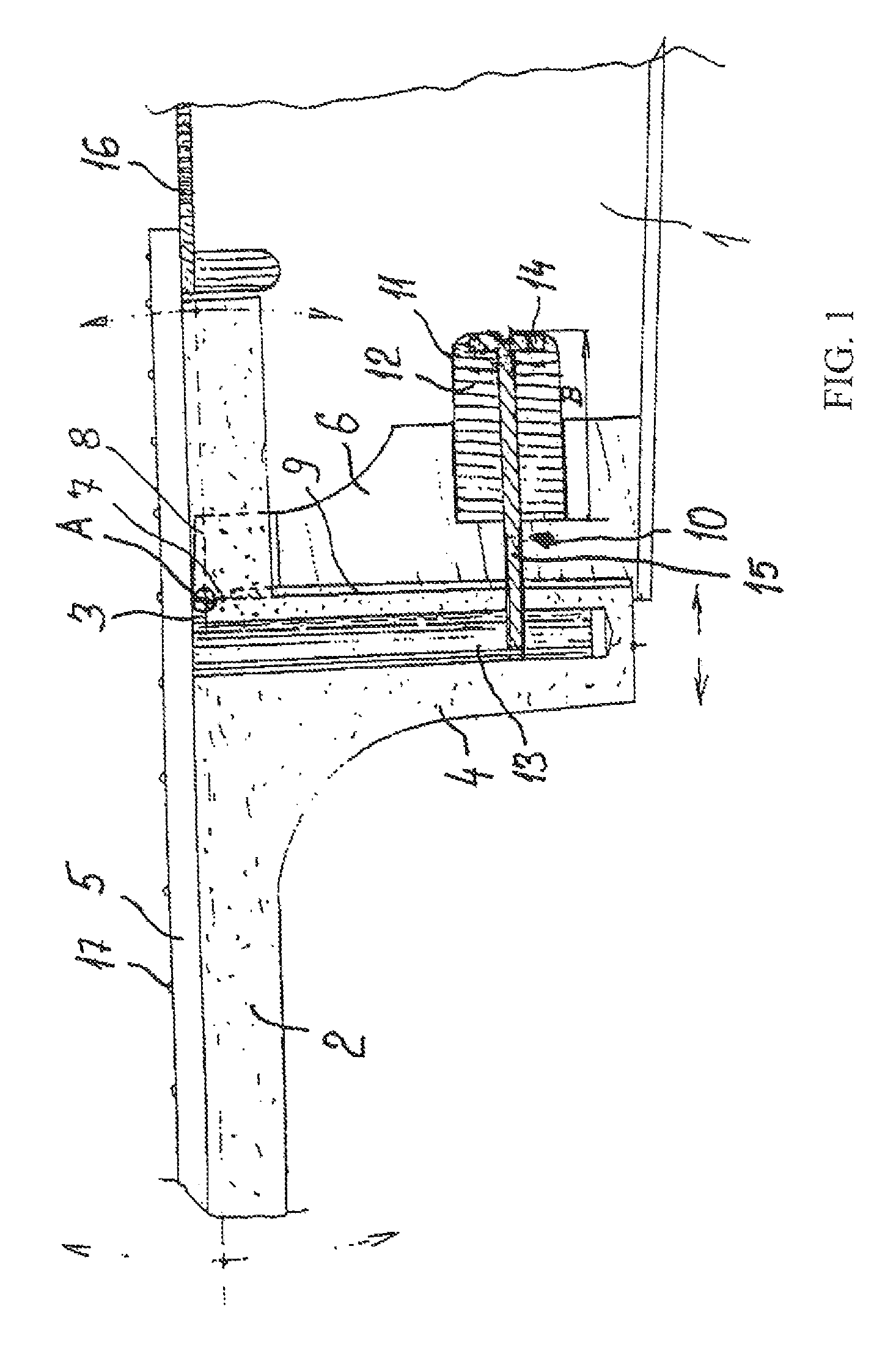

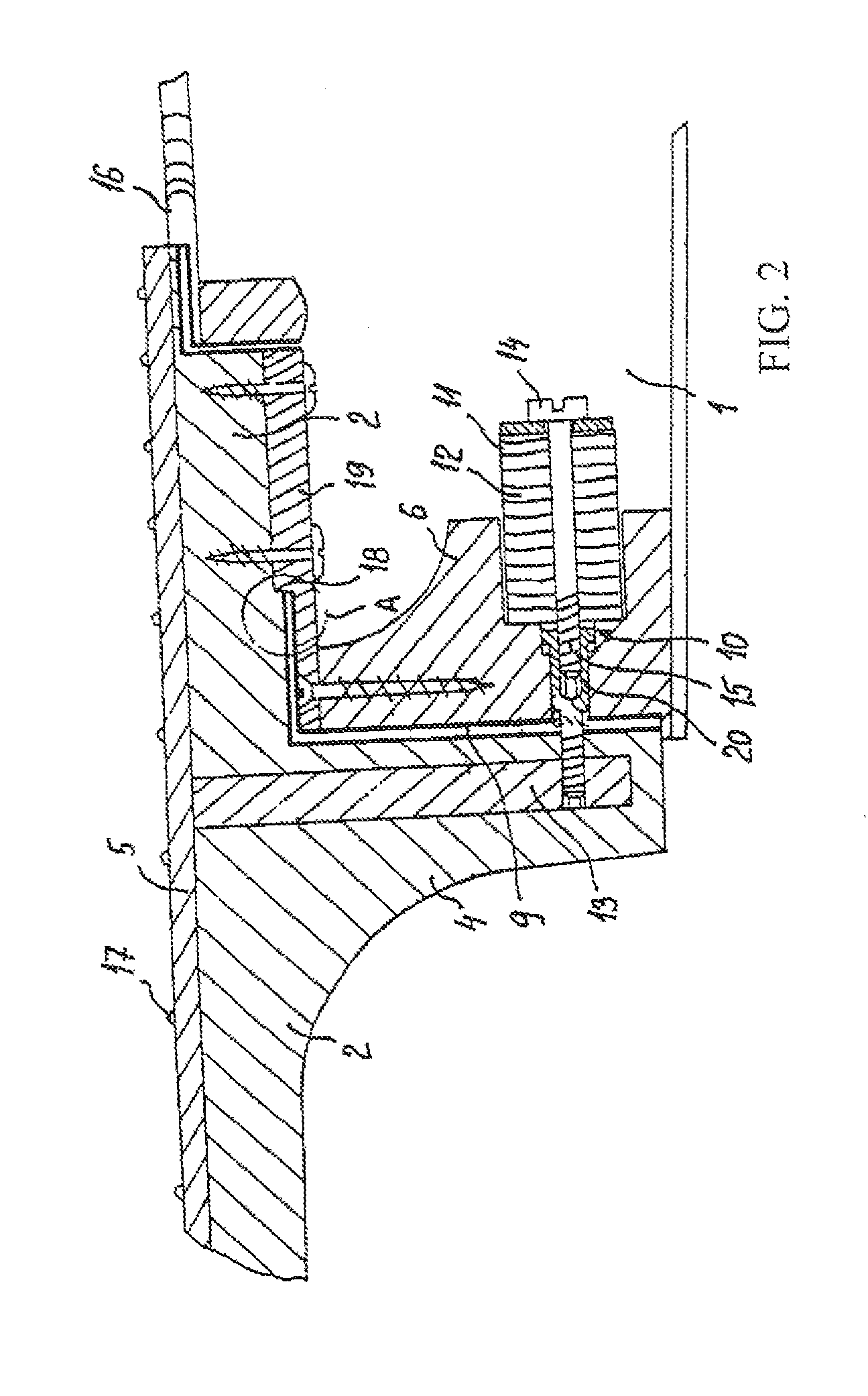

Neck for stringed instrument

Stringed instrument, especially the guitar with flexible connection of the upper part of the heel of the neck below the fingerboard to the fixing block in the body of the instrument, whereby the lower free end of the heel of the neck is coupled to a fixing block in the body of a stringed instrument through the rod via a rectification element which dilates in reaction to atmospheric humidity changes.

Owner:FURCH FRANTIHACEK OVER SEK +1

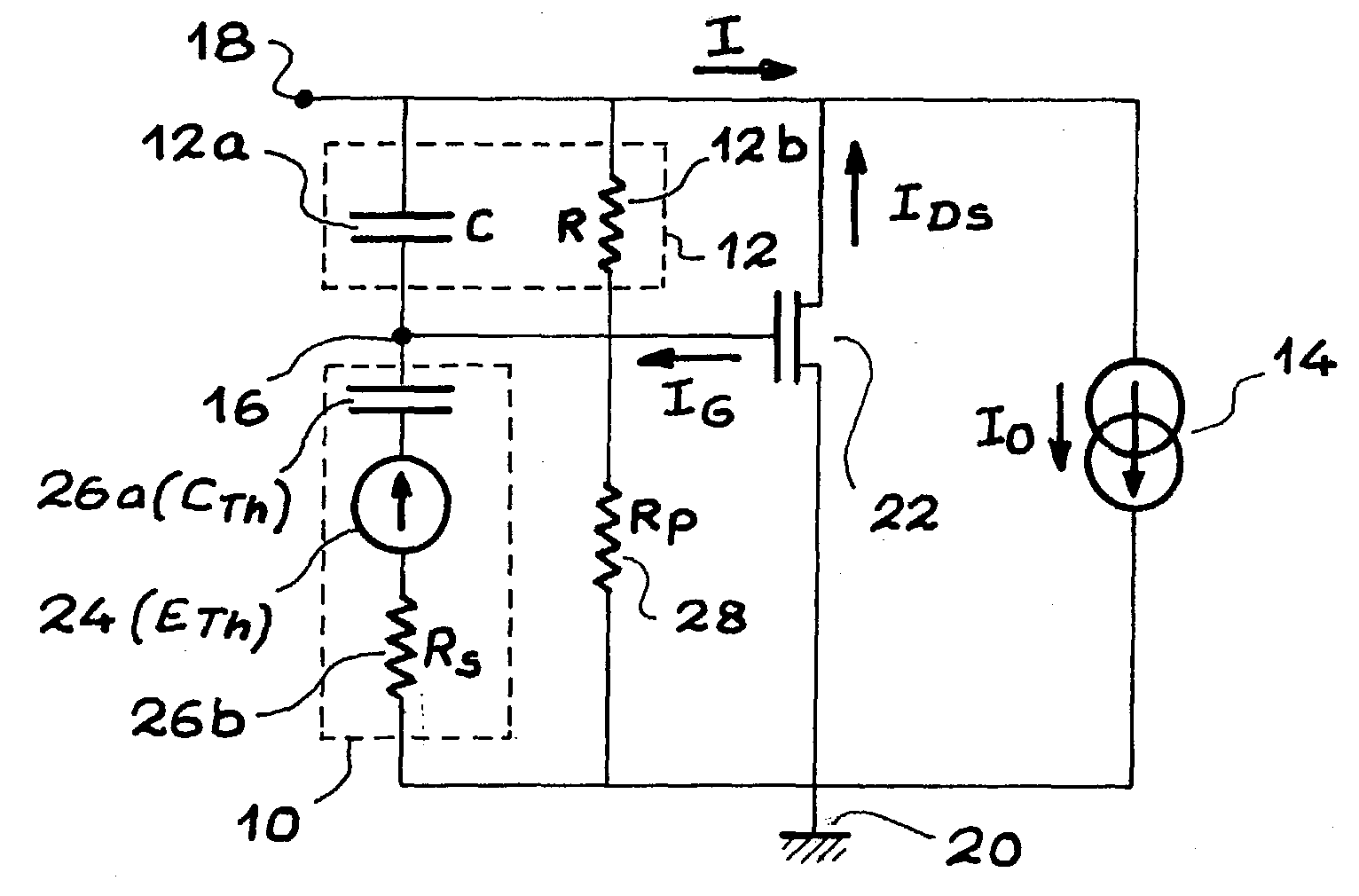

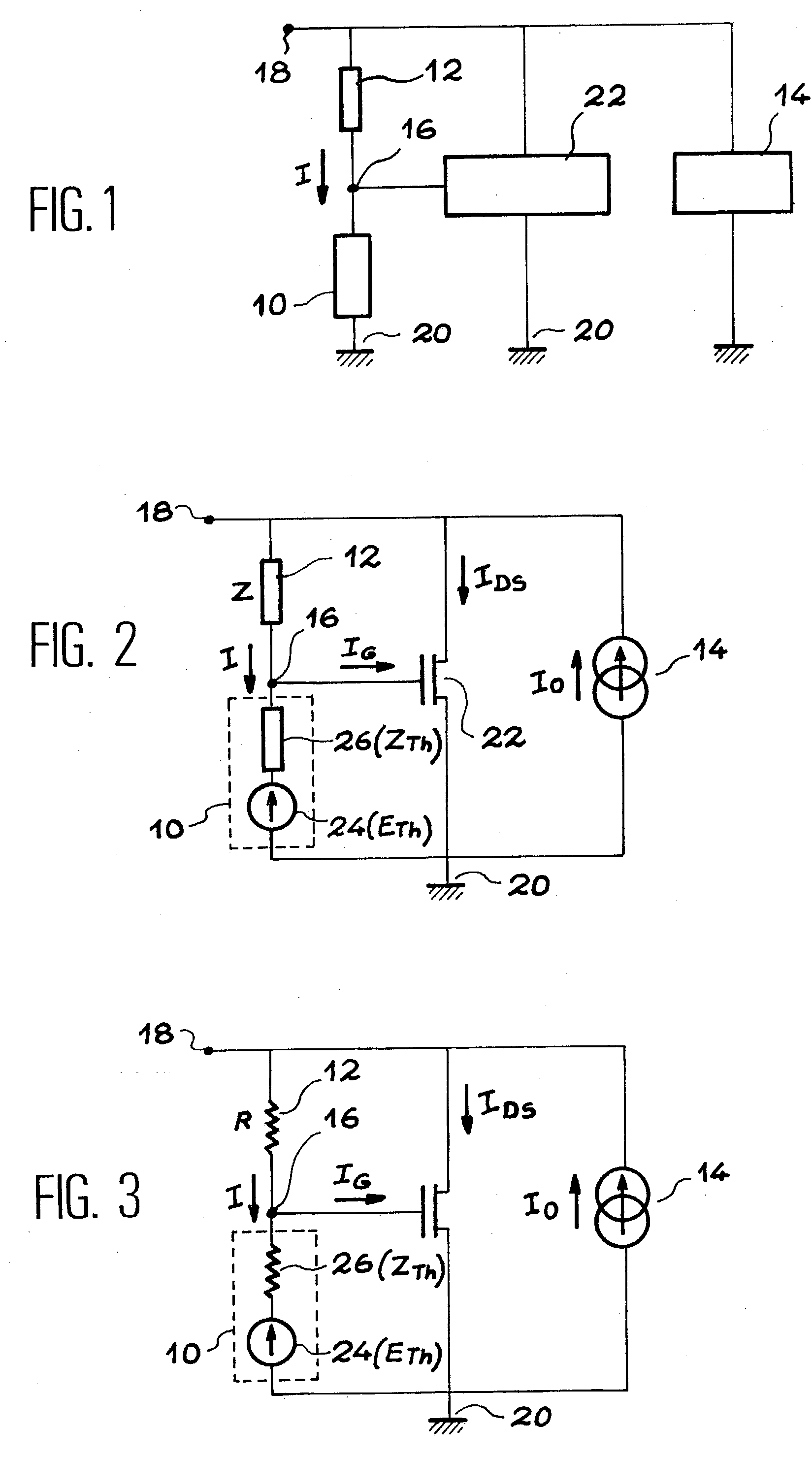

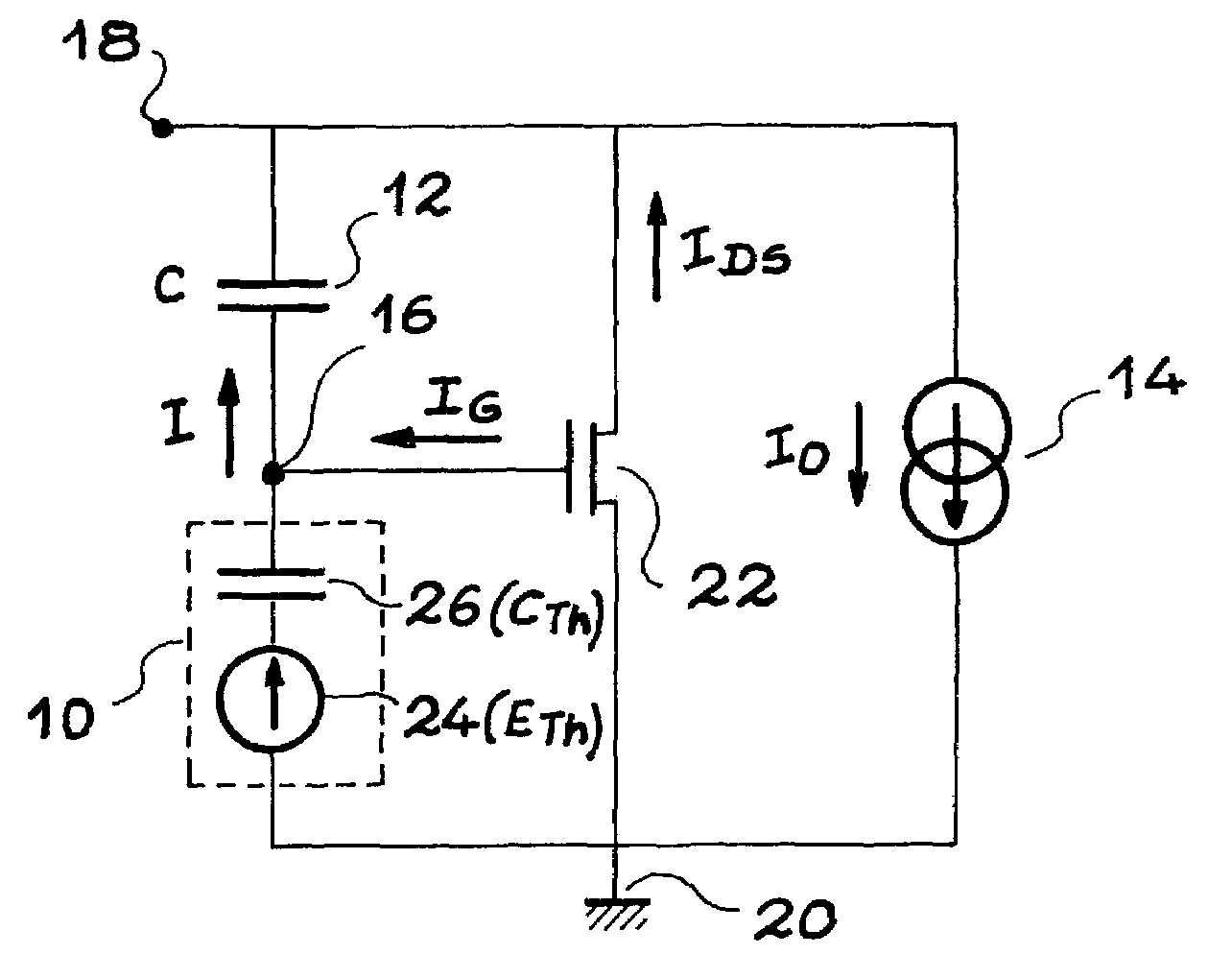

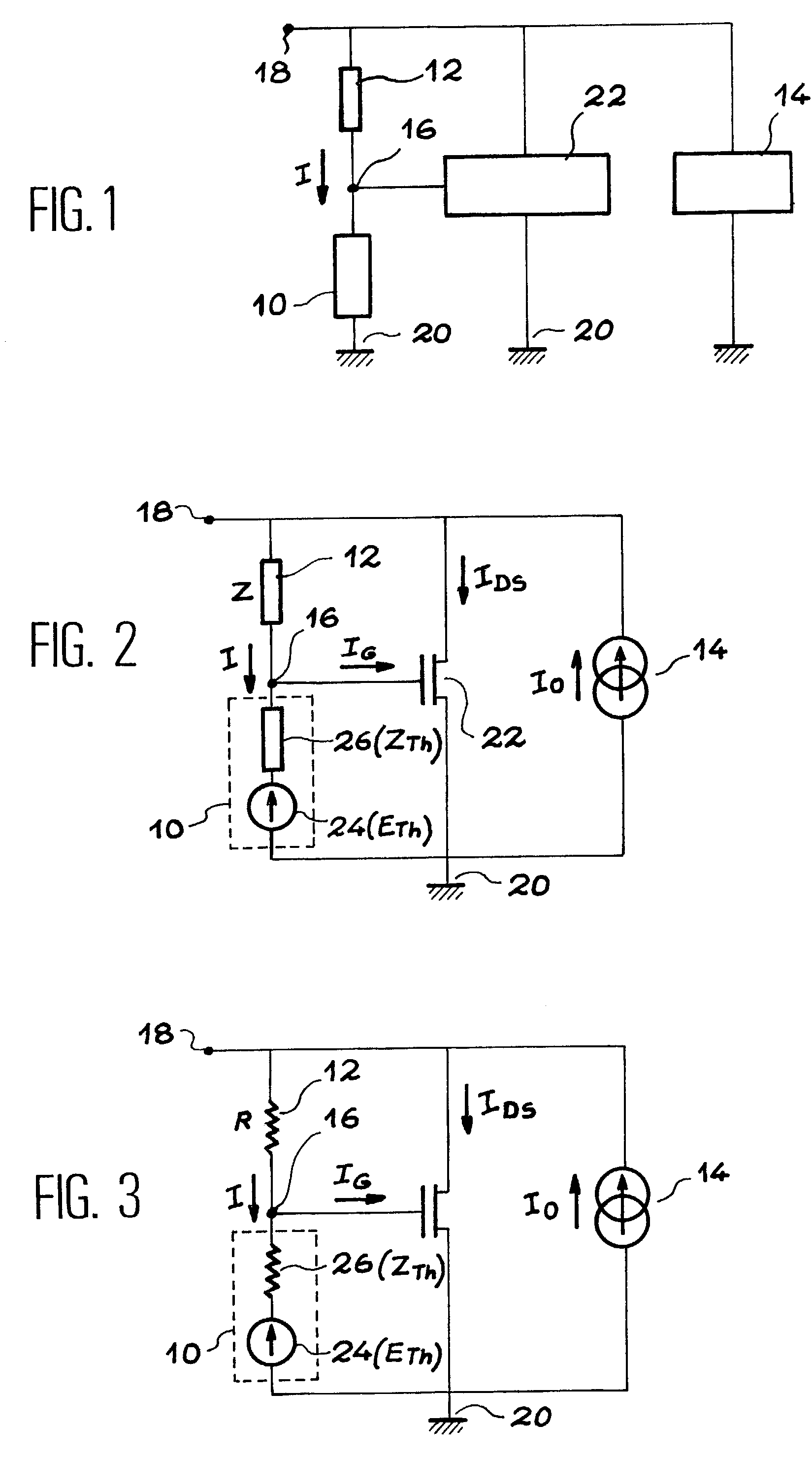

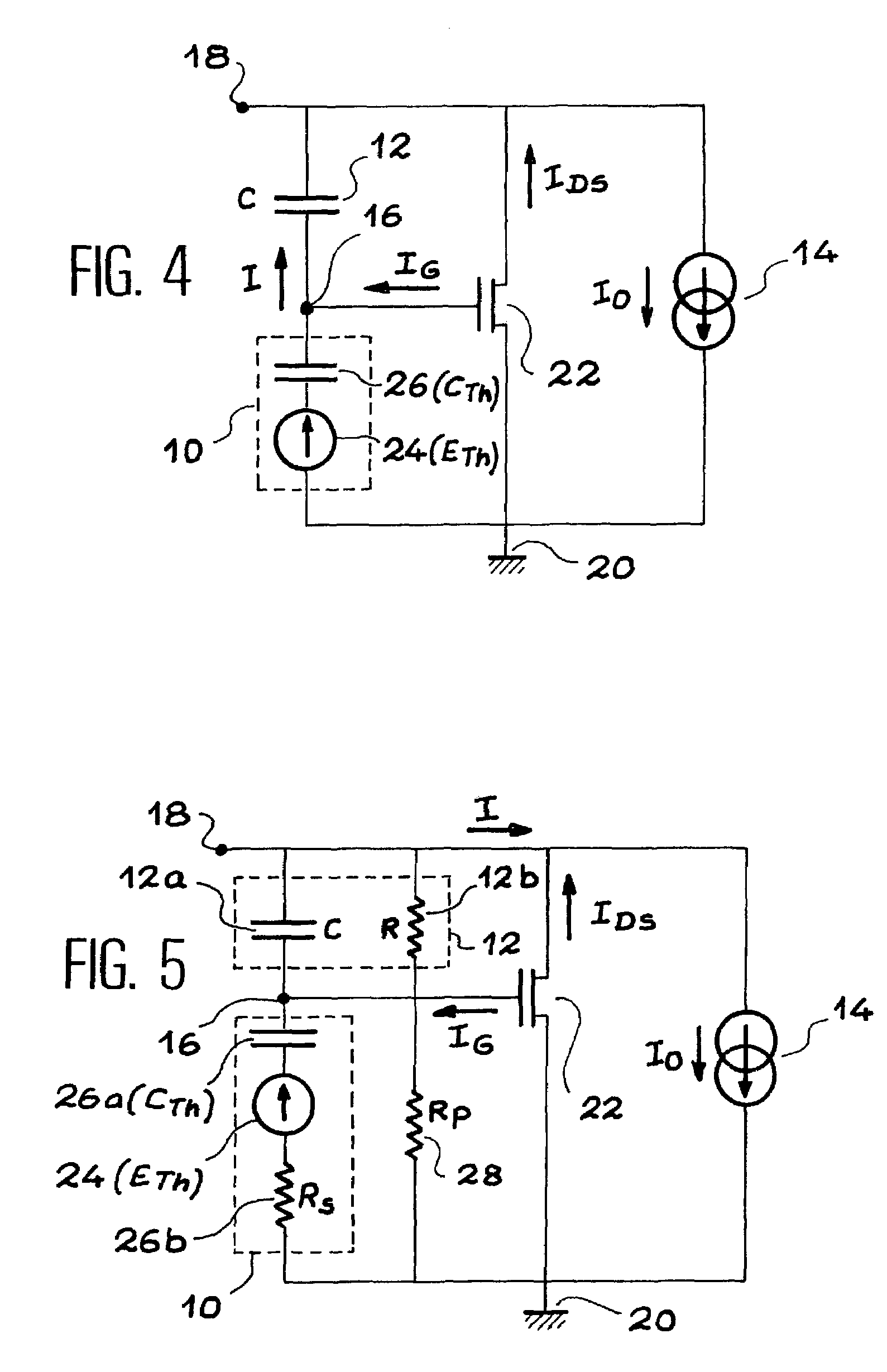

Amplifier device for sensors

InactiveUS20030147451A1High measurement accuracyLower detection thresholdThermometers using electric/magnetic elementsMaterial analysis by optical meansAudio power amplifierEngineering

Amplifying device for a sensor (10) delivering a response in voltage or impedance comprising: voltage controlling means (22 connected to output terminals (16, 20) of the sensor to maintain a noticeably constant voltage between the said terminals, at least an additional impedance (12) connected in series with the sensor within a polarisation circuit, between the output terminals (18-16; 18-20) of the said device. Application to temperatures, irradiation levels and pH measurement.

Owner:CENT NAT DE LA RECHERCHE SCI

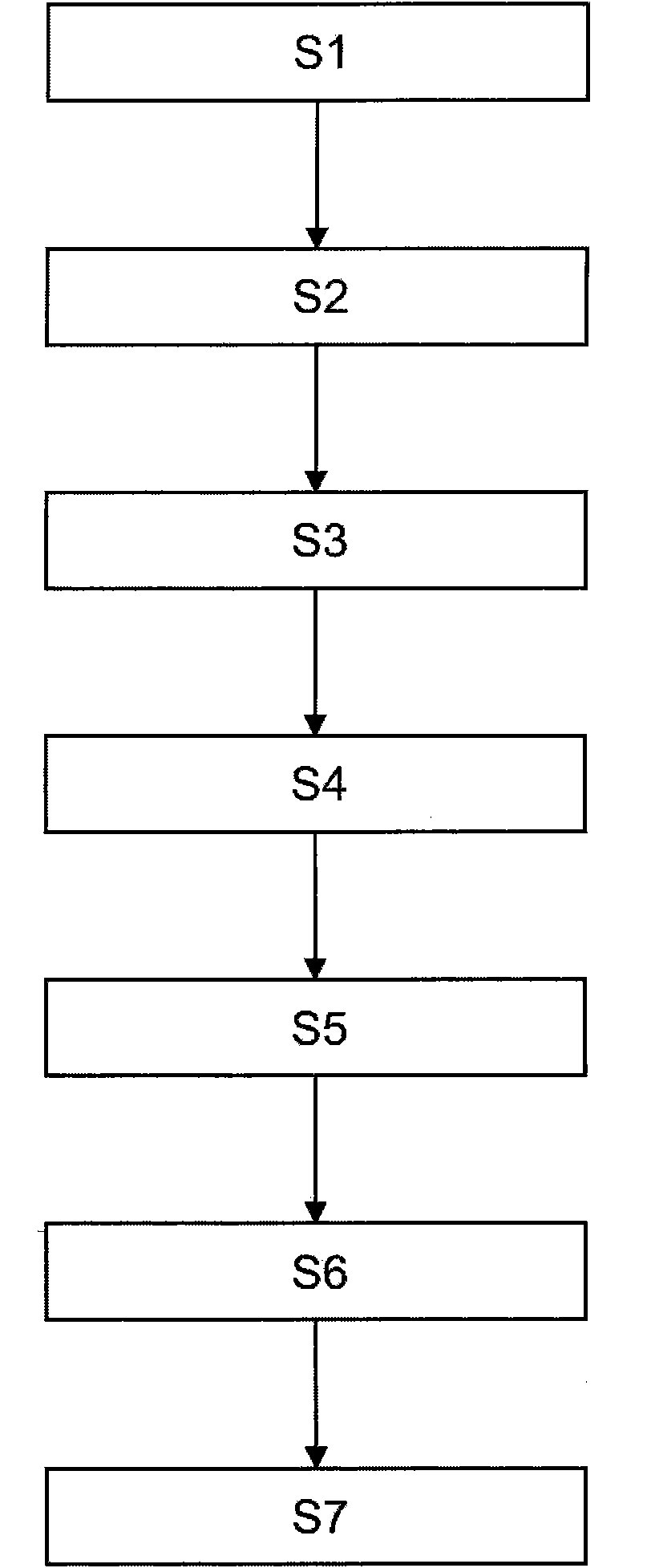

Stepping motor gage pointer zero-returning method

InactiveCN101334295AReduce jitterReduce noiseIndication apparatusProvision for operation by null methodsThree stageStructural engineering

The invention discloses a zero returning method for a meter needle of a stepper motor, which comprises the steps of: 1) the setting of a zero returning angle, an acceleration angle, an operating angle and a deceleration angle of the meter needle, wherein, the zero returning angle is equal to the acceleration angle plus the operating angle and plus the deceleration angle; 2) acceleration: the meter needle is driven to operate by acceleration to complete the acceleration angle; 3) operating: the meter needle is driven to operate by the speed after the step 2) to complete the operating angle; 4) deceleration: the speed after the step 3) is decelerated to zero and the meter needle is driven to operate to complete the deceleration angle. The method divides the zero returning of the needle into three stages, and leads the needle to complete the zero returning process smoothly, thus not only reducing the wobble of the needle, but also effectively reducing the noise during the zero returning, and avoiding the occurrence of the phenomena, such as the rebounding of the needle, and unreliable zero returning, etc.

Owner:SHANGHAI DELCO ELECTRONICS & INSTR

Inertial Zeroing Method of Automobile Meter Pointer

ActiveCN103344261BNo added complexityAvoid bouncing actionProvision for operation by null methodsMicrocomputerMicrocontroller

The invention relates to a method for enabling an automobile meter needle to point zero through inertia. The method aims to solve the problem that in an existing mode for enabling an automobile meter needle to return to the original point, a hardware circuit is added. The method comprises the following steps of (1) electrifying a stepping motor driving the automobile meter needle and setting the number n of reverse pulse signals in a register to be 0, (2) exerting a reverse pulse signal to the stepping motor through a stepping motor driver to enable the automobile meter needle to move a step towards the original point of the automobile meter needle and enabling n to be 1, (3) judging if the number n of the reverse pulse signals exerted to the stepping motor by the stepping motor driver is equal to N through a single chip microcomputer, and (4) executing the step (2) if the result of the step (3) is 'no', and ending the steps if the result of the step (3) is 'yes'.

Owner:AEROSPACE HI TECH HLDG GROUP

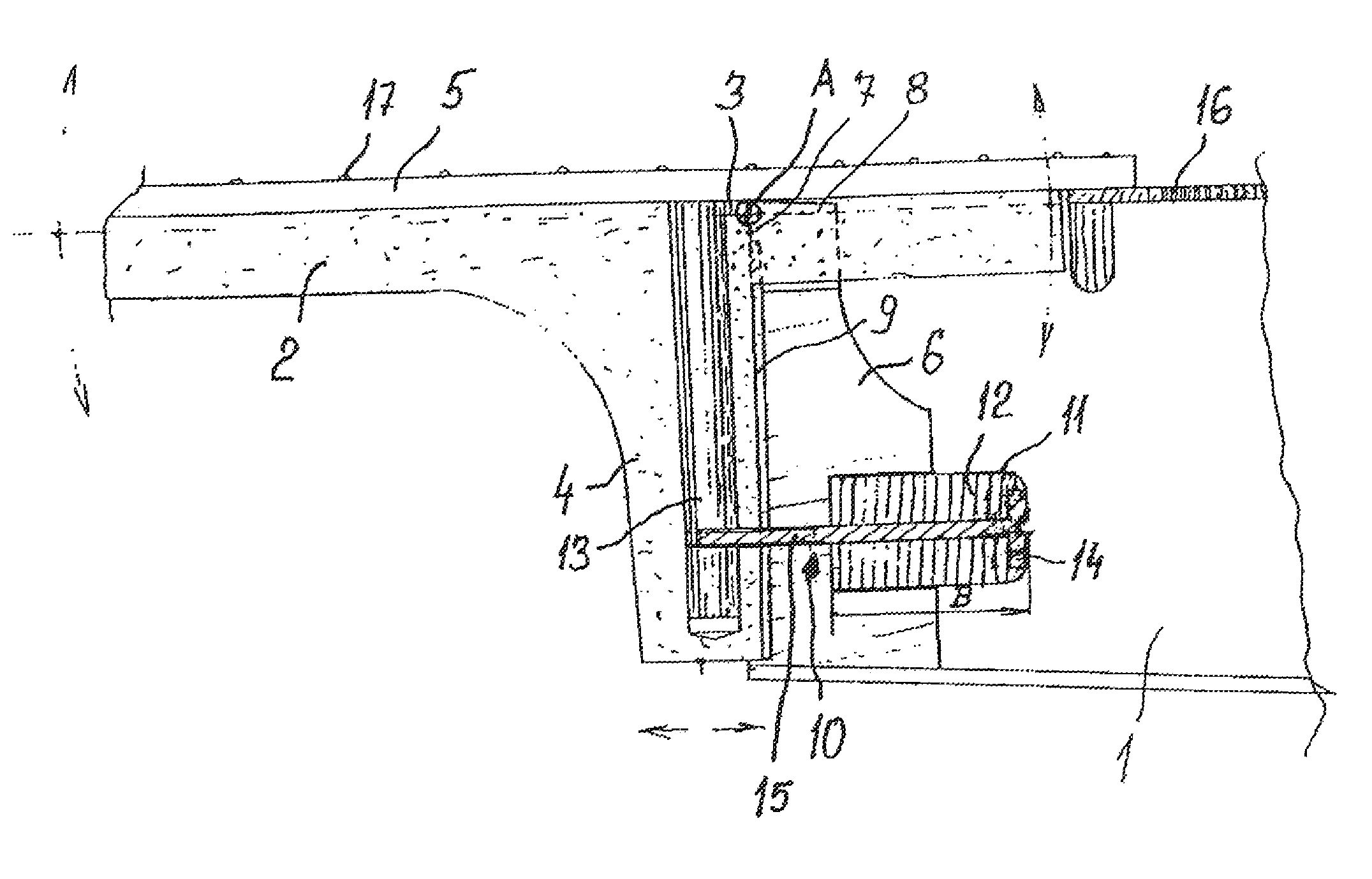

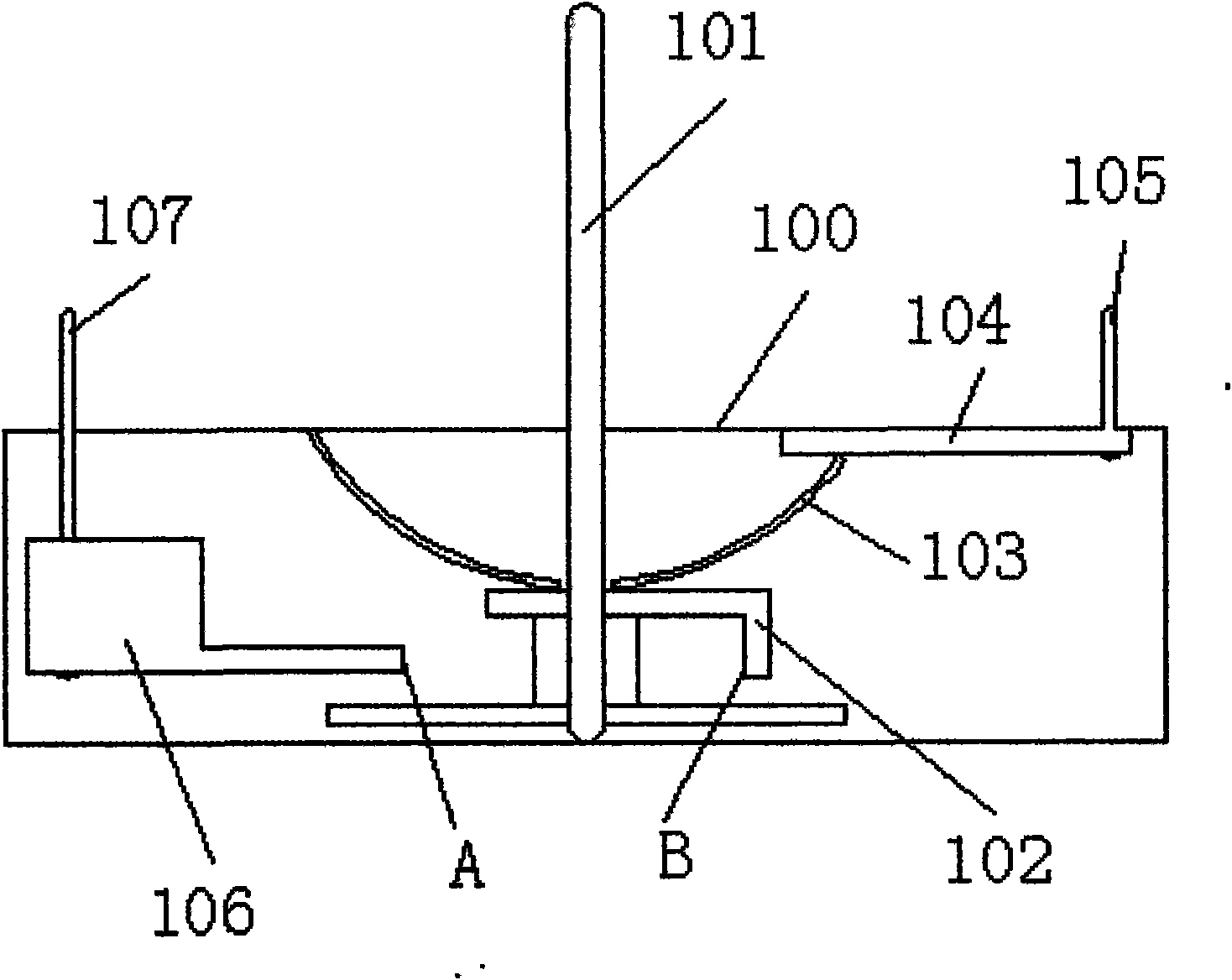

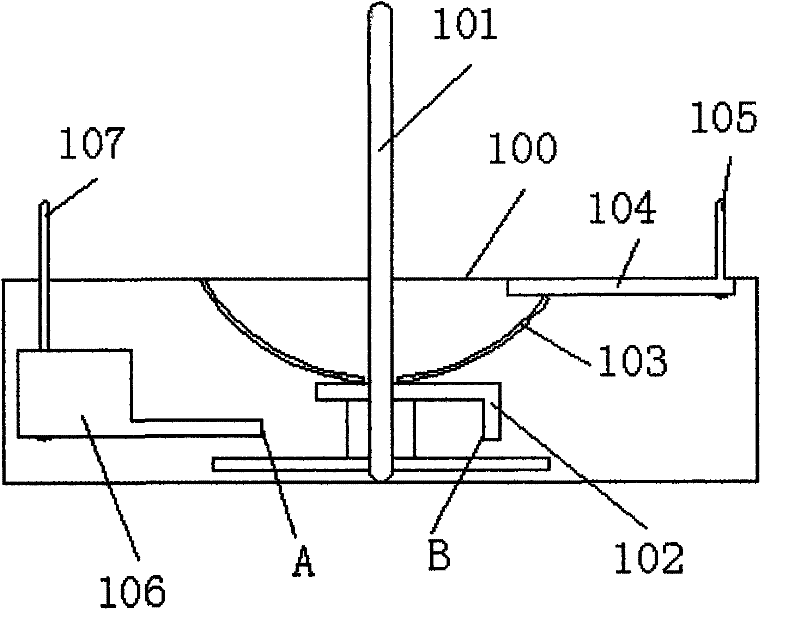

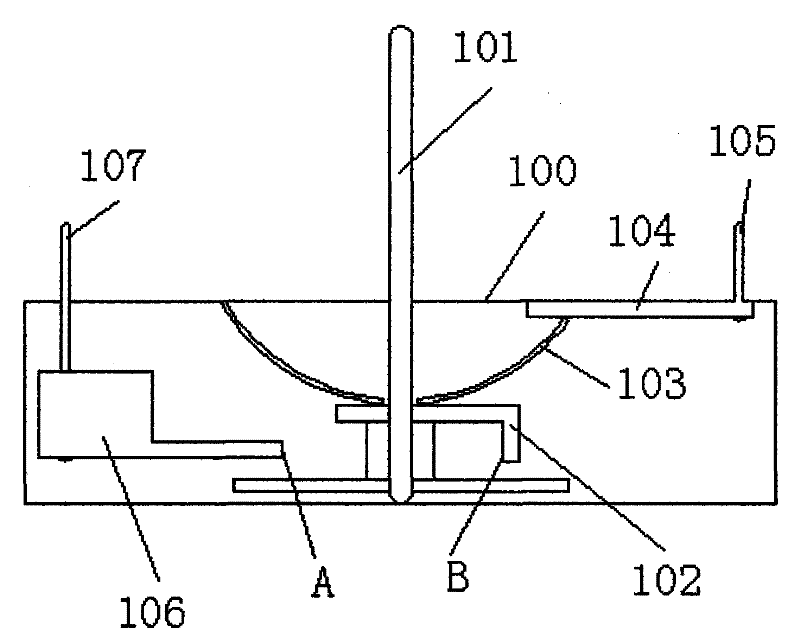

Attached switch in automobile instrument stepper motor

InactiveCN101922943AAchieve the goal of returning to zeroContact operating partsProvision for operation by null methodsDashboardThin metal

The invention discloses an attached switch in an automobile instrument stepper motor, which detects zero returning of an instrument indicator. The attached switch comprises a thin metal sheet, a thick metal sheet, a metal stopper and a wing spring, wherein a terminal pin is welded on the thin metal sheet; another terminal pin is welded on the thick metal sheet and extends to the outside of a shell; and the metal stopper is tightly pressed on an output shaft with an indicator. After assembly, the output shaft passes through a central hole of the wing spring, the metal stopper is pressed on the wing spring; one side of the wing spring is pressed on the thin metal sheet, so that the two terminal pins which are welded with the thick and thin metal sheets become two ends of a switch, one end of the switch is fixedly connected with the metal stopper, and a point A of the thick metal sheet and a point B of the metal stopper are contacts of the switch. When the output shaft rotates to a certain position towards a zero returning direction, the point A of the thick metal sheet and the point B of the metal stopper contact to show that the switch is closed; and when the output shaft rotates, the point A of the thick metal sheet is separated from the point B of the metal stopper to show that the switch is separated and indicate that the indicator departs from a zero position. Thus, the aim of detecting the zero returning of the instrument indicator is fulfilled.

Owner:NINGBO YICHENG ELECTRONICS TECH

Amplifier device for sensors

InactiveUS7009184B2High sensitivityHigh measurement accuracyDosimetersThermometers using electric/magnetic elementsAudio power amplifierEngineering

An amplifying device for a sensor (10) delivering a response in voltage or impedance has a voltage controlling means for the sensor and at least an additional impedance (12). The voltage controlling means (22) is connected to output terminals (16, 20) of the sensor to maintain a noticeably constant voltage between the terminals. The additional impedance (12) is connected in series with the sensor within a polarization circuit, between the output terminals (18–16; 18–20) of the device. The amplifying device may be applied to temperatures, irradiation levels and pH measurement.

Owner:CENT NAT DE LA RECHERCHE SCI

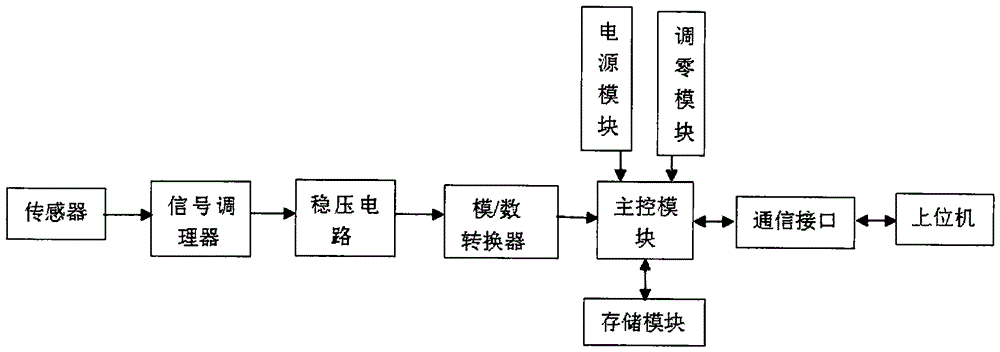

Wireless sensor system

InactiveCN106225825AImprove accuracyFast adjustmentProvision for operation by null methodsCommunication interfaceLine sensor

The invention discloses a wireless sensor system, and the system comprises a sensor, a signal conditioner, a voltage-stabilizing circuit, an analog / digital converter, a main control module, a storage module, a communication interface, an upper computer, a power module, and a zero setting module. The sensor, the signal conditioner, the voltage-stabilizing circuit, the analog / digital converter and the main control module are sequentially connected. The main control module is connected with the storage module, the power module and the zero setting module, and is connected with the upper computer through the communication interface. The system can achieve the real-time collection and processing of the data through the upper computer, is high in measurement precision, is strong in anti-interference capability, is long in transmission distance, is convenient for zero setting, and is suitable for popularization and application.

Owner:商丘学院

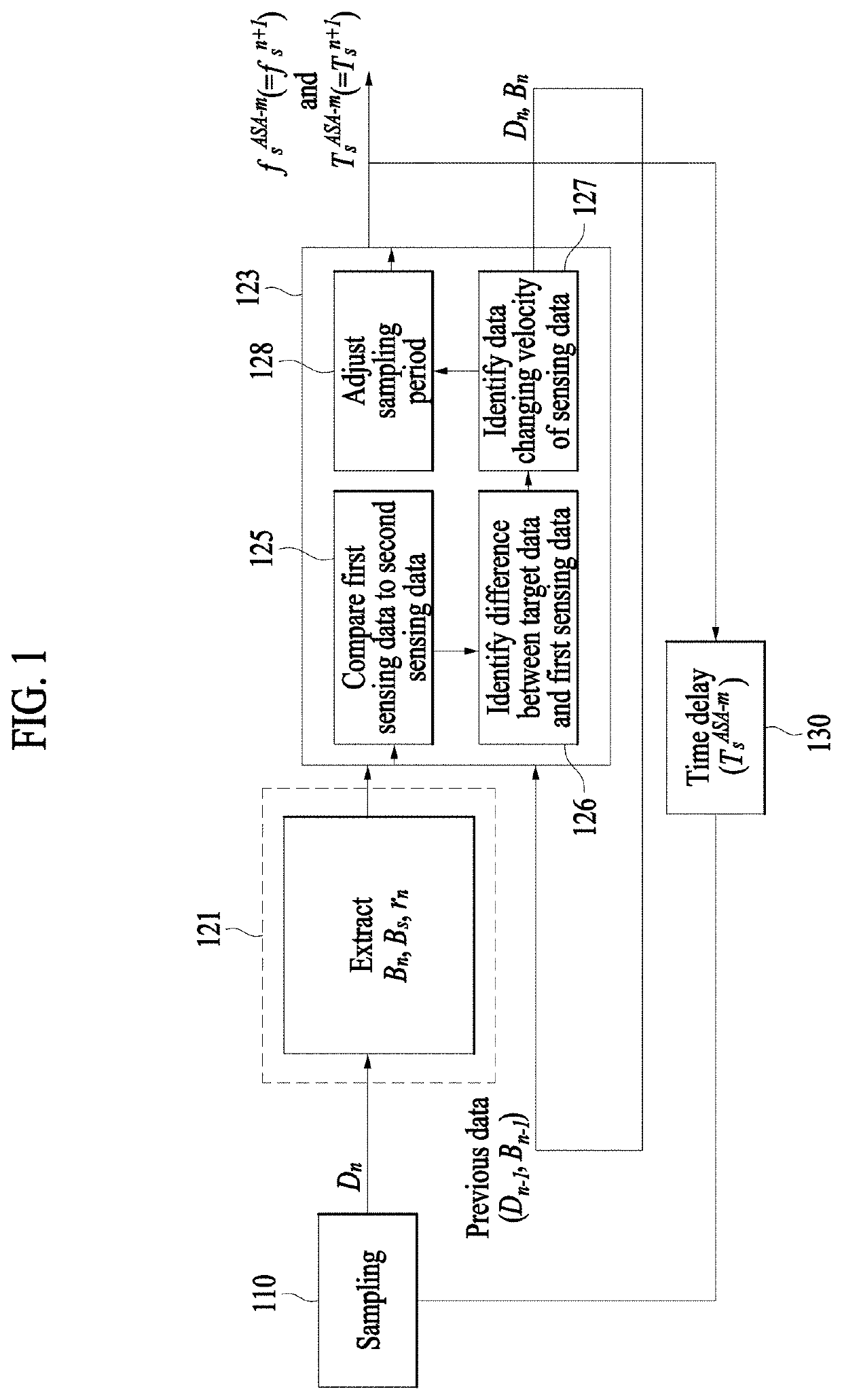

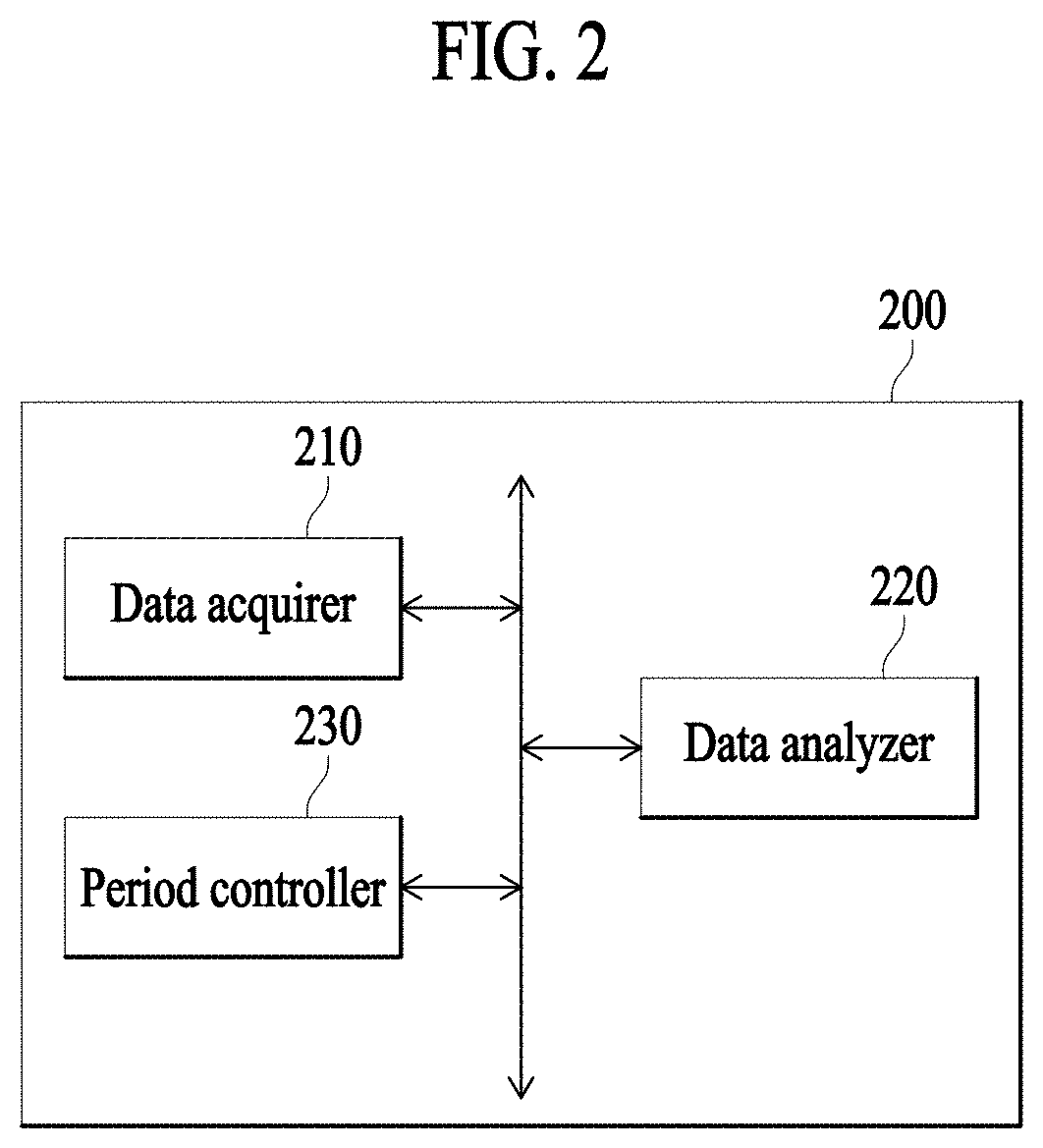

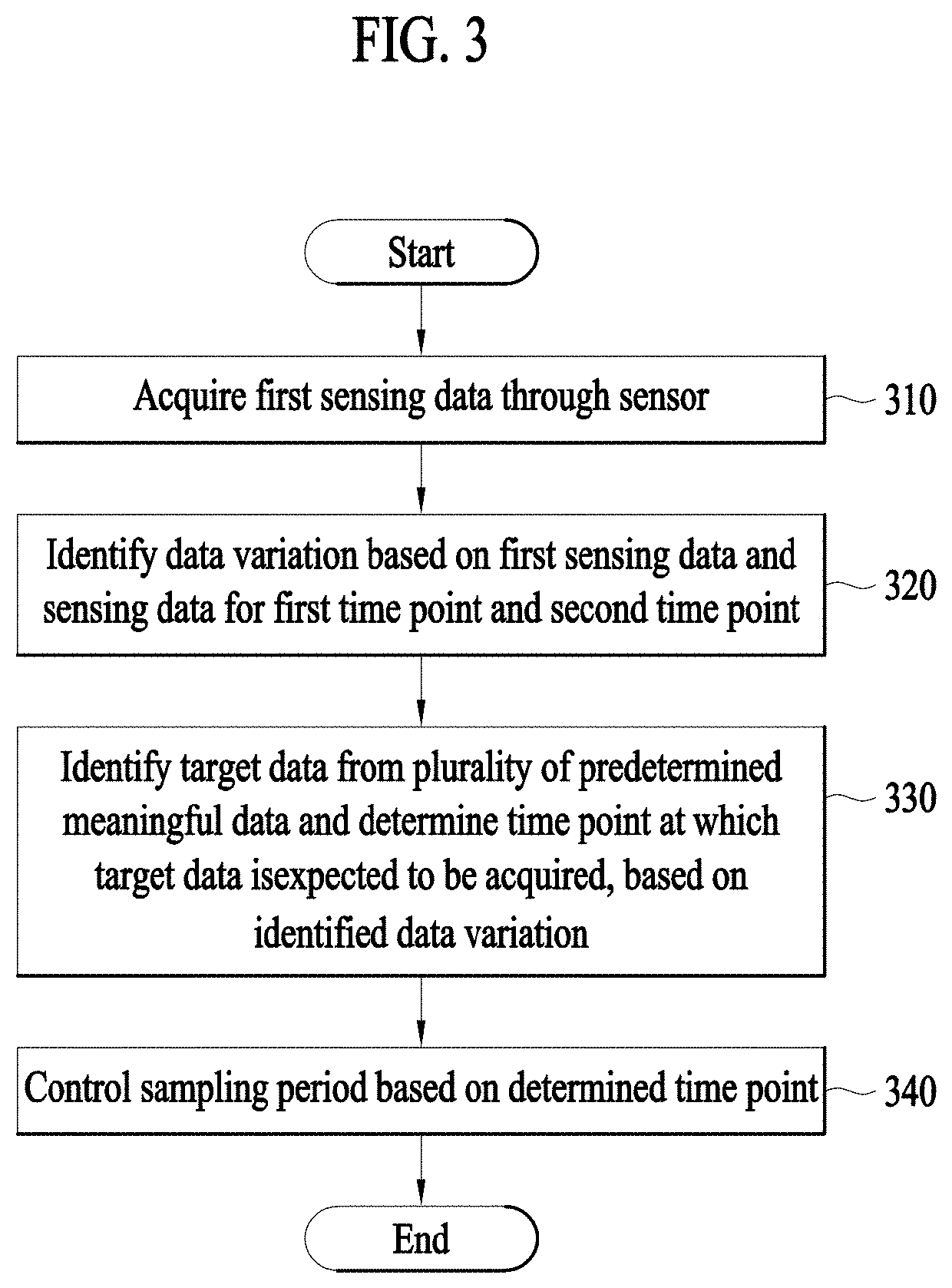

Electronic apparatus for controlling sensor and operation method thereof

PendingUS20220187100A1Useful energyGuarantee data qualityThermometer detailsAnalogue/digital conversionSensing dataEngineering

The disclosure generally relates to devices and techniques for operating an electronic apparatus that controls a sensor, the devices and techniques including acquiring first sensing data through the sensor, identifying a data variation based on the first sensing data and sensing data for a first time point and a second time point acquired in advance based on a sampling period of the sensor, identifying target data among a plurality of predetermined meaningful data based on the identified data variation and determining a time point at which the target data is to be acquired, and controlling the sampling period based on the determined time point.

Owner:AGENCY FOR DEFENSE DEV

Current production equipment for generating and monitoring and measuring the electric current

ActiveCN101806823BCurrent/voltage measurementProvision for operation by null methodsHemt circuitsControl theory

The device (100) has a current source (103) generating a measuring current (101). Another current source (104) generates a compensating current (105) in order to compensate a part of the measuring current. A detection circuit (106) detects a deviation of the measuring current from a nominal value on the basis of the compensating current, where detection of the deviation is performed using a voltage measurement process. A current-sensing resistor unit (108) is provided such that compensating current flows through the current-sensing resistor unit. Independent claims are also included for the following: (1) a method for the generation and simultaneous monitoring of a measuring current for one of a level meter, a pressure gauge and a flowmeter (2) a program element instructing a processor to perform a method for the generation and simultaneous monitoring of a measuring current (3) a computer-readable medium to perform a method for the generation and simultaneous monitoring of a measuring current.

Owner:VEGA GRIESHABER GMBH & CO

Attached switch in automobile instrument stepper motor

InactiveCN101922943BAchieve the goal of returning to zeroContact operating partsProvision for operation by null methodsThin metalMetal sheet

The invention discloses an attached switch in an automobile instrument stepper motor, which detects zero returning of an instrument indicator. The attached switch comprises a thin metal sheet, a thick metal sheet, a metal stopper and a wing spring, wherein a terminal pin is welded on the thin metal sheet; another terminal pin is welded on the thick metal sheet and extends to the outside of a shell; and the metal stopper is tightly pressed on an output shaft with an indicator. After assembly, the output shaft passes through a central hole of the wing spring, the metal stopper is pressed on thewing spring; one side of the wing spring is pressed on the thin metal sheet, so that the two terminal pins which are welded with the thick and thin metal sheets become two ends of a switch, one end of the switch is fixedly connected with the metal stopper, and a point A of the thick metal sheet and a point B of the metal stopper are contacts of the switch. When the output shaft rotates to a certain position towards a zero returning direction, the point A of the thick metal sheet and the point B of the metal stopper contact to show that the switch is closed; and when the output shaft rotates, the point A of the thick metal sheet is separated from the point B of the metal stopper to show that the switch is separated and indicate that the indicator departs from a zero position. Thus, the aim of detecting the zero returning of the instrument indicator is fulfilled.

Owner:NINGBO YICHENG ELECTRONICS TECH

Static monitor repeats display platform sensor zero position adjustment method

ActiveCN109443394BHigh precision requirementsIngenious design ideasProvision for operation by null methodsControl engineeringComputer science

The invention relates to a method for adjusting the zero position of an electrostatic monitor repeating platform sensor, comprising the following steps: (1) preparation work for zero adjustment of an angle sensor and a position sensor; (2) zero adjustment of the right and stern angle sensors; ⑶. Zero adjustment of bow and left position sensors. The design idea of the achievement of the present invention is ingenious and innovative, and provides a method for adjusting the zero position of the sensor of the electrostatic monitor repeating platform. Using this method can ensure precision assembly accuracy, meet the high-precision requirements of the electrostatic repeating platform, and improve work efficiency. , Guaranteed product quality, has promotional value.

Owner:TIANJIN NAVIGATION INSTR RES INST

Zero-debugging method of sensor for main control valve of steering engine actuator

ActiveCN101915589BImprove assembly efficiencyImprove debugging efficiencyProvision for operation by null methodsControl valvesActuator

The invention belongs to a sensor debugging technique and relates to the improvement on a zero-debugging method of a sensor for a main control valve of a steering engine actuator. The zero-debugging method is used for carrying out mechanical zero debugging to a sensor [5] and comprises the following steps of: adjusting a gap between a flexible rod [2] and a sensor bush [3]; measuring the change amounts of four-channel output values of the sensor [5]; and adjusting the angle of the sensor bush [3]. The zero-debugging method can solve the problem of the ultra-poor consistency of the four-channel output values of the sensor after the main control valve is installed on the steering engine actuator and improve the assembling and debugging efficiency of the steering engine actuator.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

Electrostatic monitor repeating platform sensor zero position adjustment method

ActiveCN109443394ASimple structureEasy to installProvision for operation by null methodsEngineeringPosition sensor

The invention relates to an electrostatic monitor repeating platform sensor zero position adjustment method. The method includes following steps of: (1) preparations for the zero position adjustment of angle sensors and position sensors; (2) the zero position adjustment of the right angle sensor and stern angle sensor; and (3) the zero position adjustment of the stern position sensor and the leftposition sensor. The electrostatic monitor repeating platform sensor zero position adjustment method of the invention has the advantages of ingenious design idea and innovativeness. With the electrostatic monitor repeating platform sensor zero position adjustment method adopted, the accuracy of precision assembly can be ensured, the high precision requirements of an electrostatic repeating platform can be satisfied, working efficiency is improved, and the quality of products is ensured. The method is worthy of being popularized.

Owner:TIANJIN NAVIGATION INSTR RES INST

Automatic zeroing method and equipment for incremental sensor

The invention relates to an automatic zeroing method and automatic zeroing equipment for an incremental sensor. The method comprises the following steps of: (1) arranging a zero point detection device at the middle position of a motion stroke; (2) symmetrically arranging switches W+ and W- in the stroke directions on the two sides of a zero point; (3) arranging a zero point-centered baffle sheet on a rotating body, wherein a signal is 1 when a photoelectric switch is baffled by the baffle sheet, while the signal is 0 when the photoelectric switch is not baffled by the baffle sheet; (4) continuously detecting the values of the W+ and W- during zero-crossing by an electric control system; (5) continuously checking a zero point signal, zeroing the reading of an angular sensor when the zero point signal takes effect, or automatically zeroing the reading of the angular sensor by hardware when the zero point signal takes effect; and (6) indicating that zeroing fails if detecting that the states of the W+ and W- are changed into 01 from 10, or 10 from 01 but not detecting the zero point signal during the zero-crossing, and zeroing again. The method and the equipment overcome the defects of the prior art and can quickly judge the zeroing direction, shorten a redundancy stroke and realize high-efficiency automatic zeroing.

Owner:NANJING NAIERSI PHOTOELECTRIC INSTR

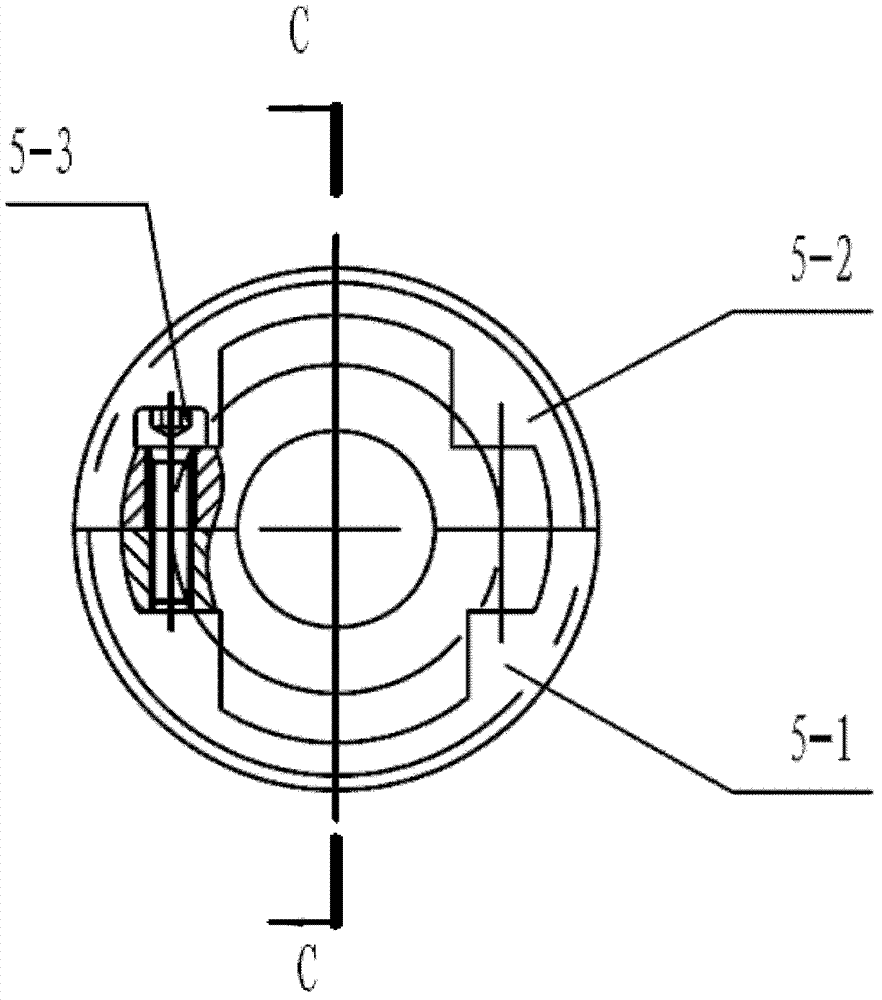

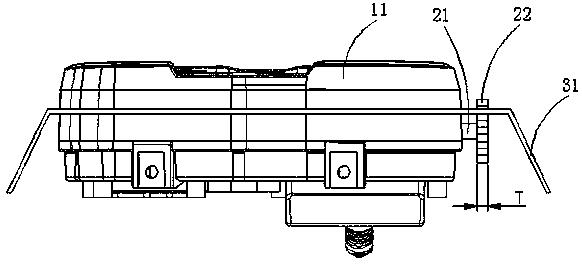

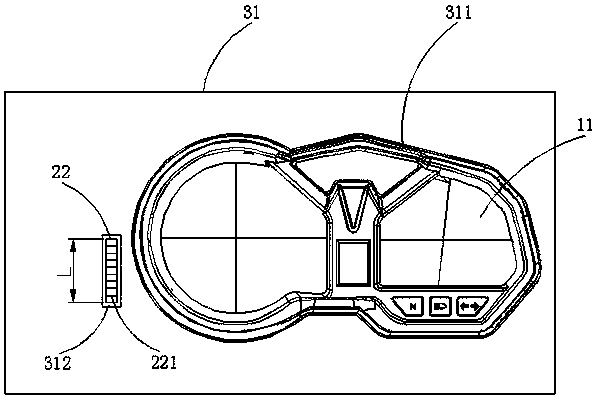

A semi-hidden meter with a subtotal mileage zero adjustment mechanism

ActiveCN104061948BEasy to useReduce weightProvision for operation by null methodsEngineeringZero mean

A semi-hidden meter with a sub-meter mileage zero-adjusting mechanism, comprising an instrument body, a zero-adjusting mechanism and an instrument back panel; the instrument body includes an instrument shell and an instrument movement arranged in the instrument shell; the zero-adjusting mechanism It includes a zero-adjustment crossbar and a tooth-type zero-adjustment knob arranged at one end of the zero-adjustment crossbar, and the other end of the zero-adjustment crossbar is connected with the instrument movement in the instrument shell; the instrument back panel is provided with A first window and a second window, the instrument body is sleeved on the first window, and the tooth-type zero adjustment knob of the zero adjustment mechanism is sleeved on the second window. In the semi-hidden meter with the subtotal mileage zero adjustment mechanism provided by the present invention, the meter body and part of the zero adjustment knob can be covered by the meter back panel, which not only improves the overall appearance effect, but also solves the problem when the user washes the car. The possibility that the instrument is easy to enter the water; at the same time, the user's zero adjustment can be adjusted from horizontal to vertical, thereby saving the design space of the whole vehicle.

Owner:LONCIN MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com