Method for enabling automobile meter needle to point zero through inertia

A technology of automobile instrument and pointer, which is applied in the field of zeroing of automobile instrument pointer, can solve the problem of adding hardware circuit settings, and achieve the effect of avoiding bouncing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

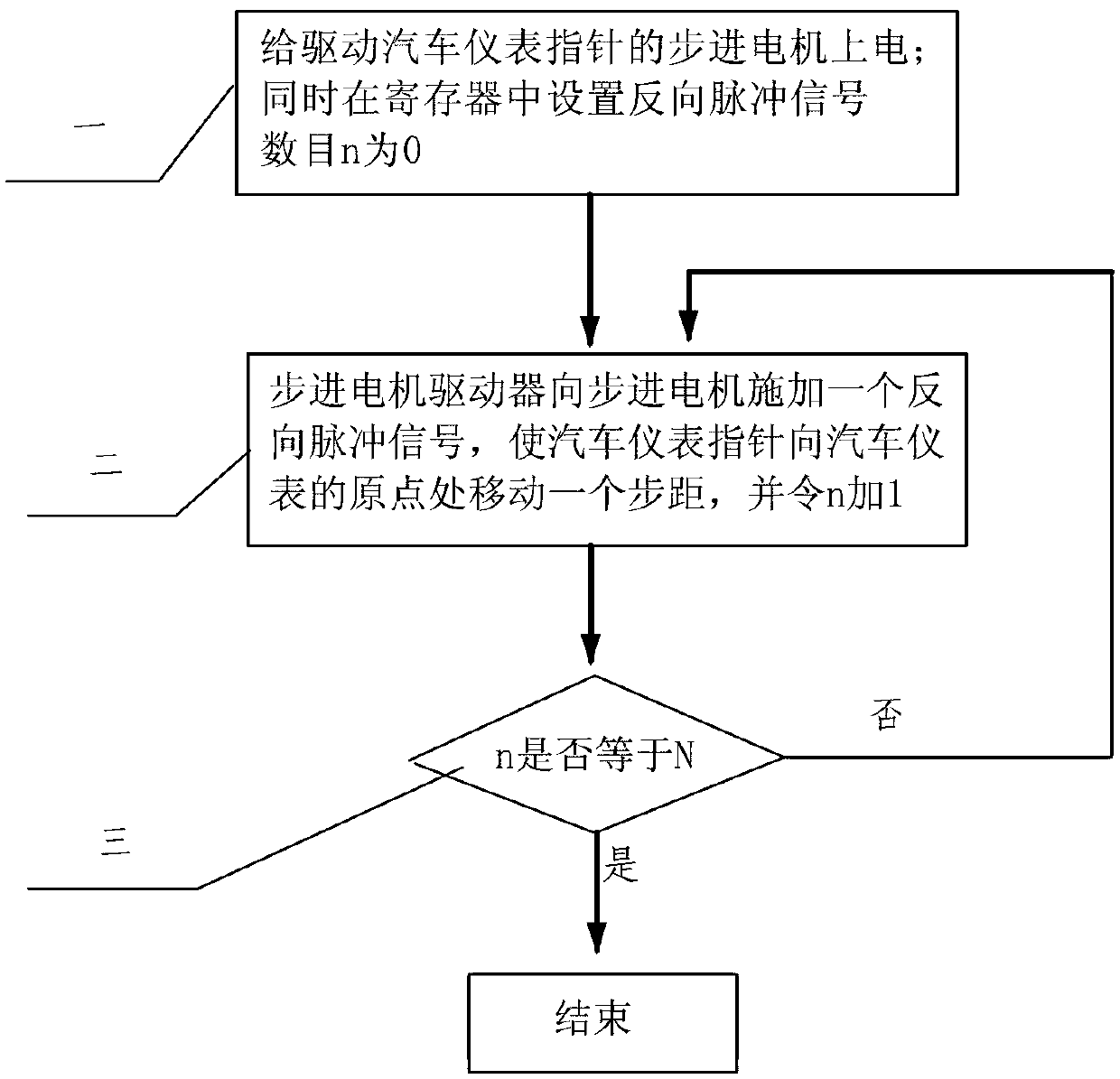

[0008] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment comprises the following steps: 1. Power on the stepper motor that drives the pointer of the automobile meter; at the same time, set the number n of reverse pulse signals in the register to be 0; 2. The stepper motor driver applies a reverse pulse signal to the stepper motor The pulse signal makes the pointer of the automobile instrument move a step to the origin of the automobile instrument, and makes n increase by 1; 3. The single-chip microcomputer judges whether the number of reverse pulse signals n applied by the stepper motor driver to the stepper motor is equal to N; N is equal to 9. The stepping motor in the present invention selects the Delta instrument panel motor of the SA20S36F-007A model, and the stepping angle of the motor is 10 degrees ± 0.5 degrees. This type of stepping motor has 2 sets of upper and lower claw stages, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com