Automatic zeroing method and equipment for incremental sensor

A sensor and incremental technology, applied in the direction of operation through zero adjustment, can solve the problems of wasting time and power, error-prone, low efficiency, etc., and achieve the effect of shortening redundant strokes and efficient automatic zero return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The height axis automatic zeroing system of the 400mm horizon telescope has a rotation range of 180 degrees.

[0028] The processing flow is as follows:

[0029] 1. The position detection device of the azimuth axis is an incremental laser grating code disc, and its zero-position engraved line is adjusted to the middle position of the running stroke during installation;

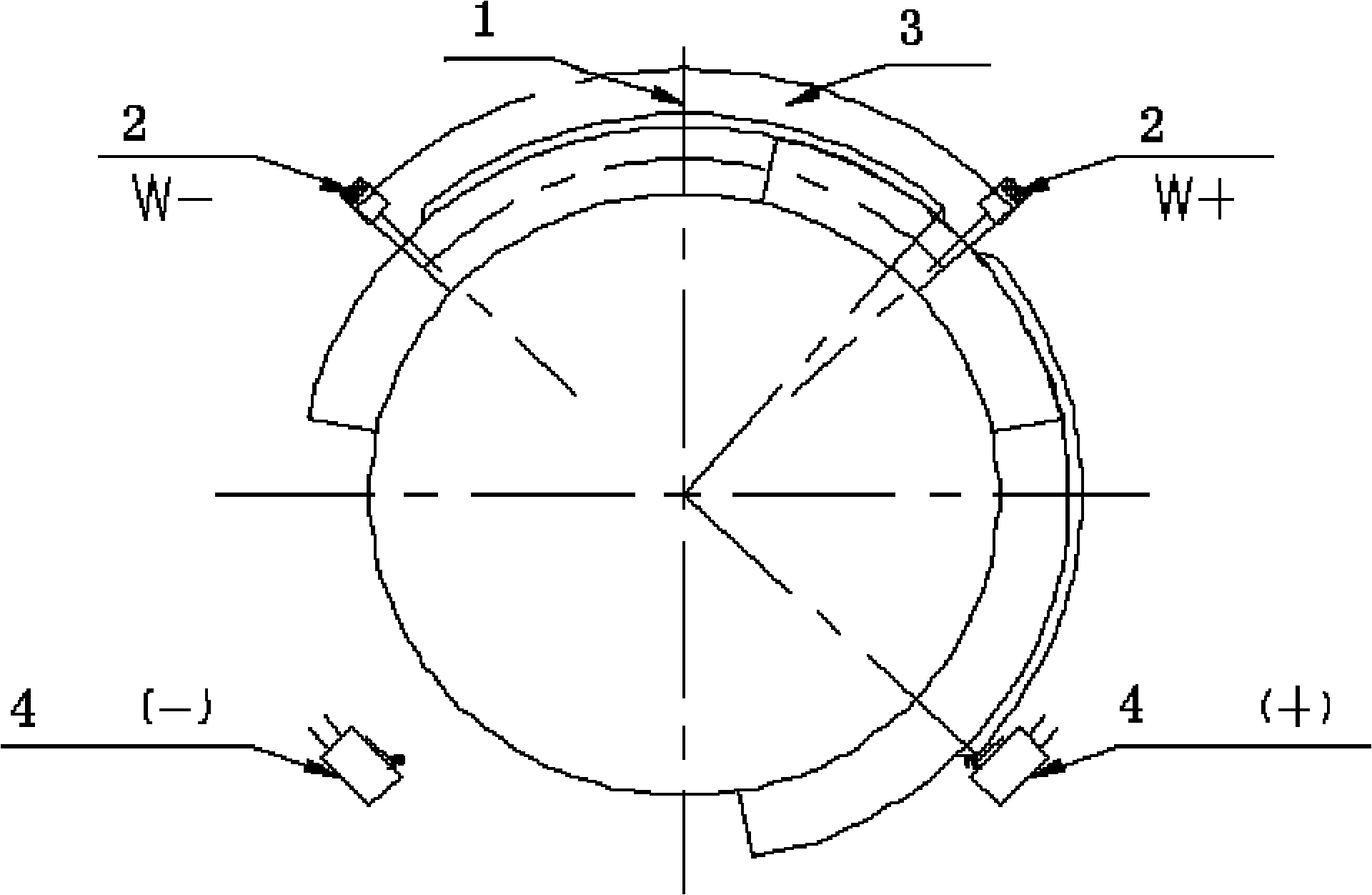

[0030] 2. On both sides of the zero point 1 (in the travel direction), install a mechanical switch (or photoelectric switch, etc.) 2 symmetrically, denoted as W+, W-, and the angle between the installation position and the zero point is ±46 degrees;

[0031] 3. On the rotating body of the incremental sensor, install a mechanical stopper 3, the stopper is centered on the zero point, and the axial angle of the stopper is 102 degrees. When the photoelectric switch is blocked by the block, its signal is 1, and the signal is 0 when it is not blocked;

[0032] 4. When crossing zero, the electr...

Embodiment 2

[0038] Embodiment 2: The azimuth axis automatic zeroing system of the 400mm horizon telescope has a rotation range of 360 degrees.

[0039] The processing flow is as follows:

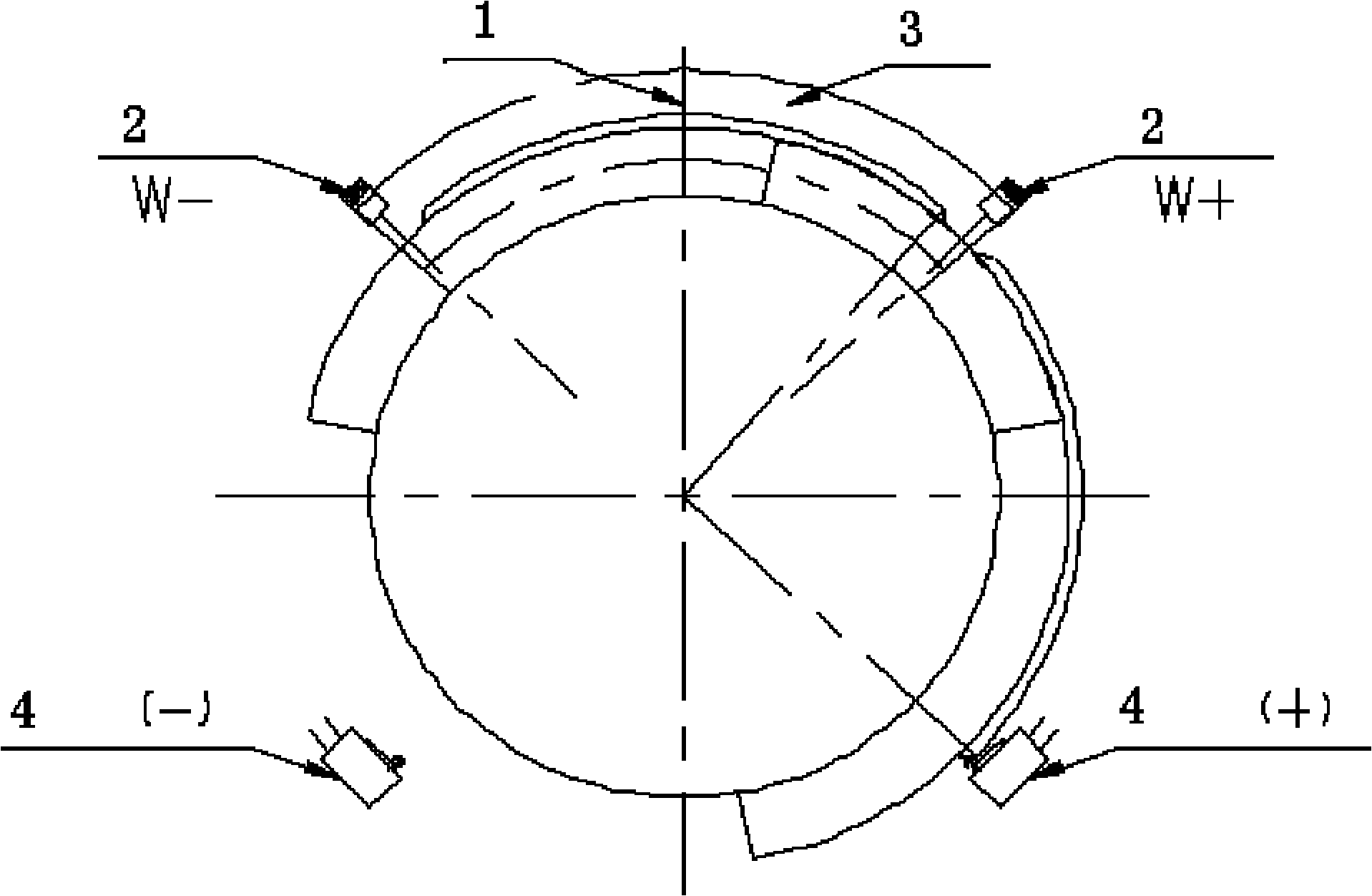

[0040] 1. The position detection device of the azimuth axis is an incremental laser grating code disc, and its zero-position engraved line is adjusted to the middle position of the running stroke during installation;

[0041] 2. On both sides of the zero point (in the travel direction), symmetrically install a mechanical switch (or photoelectric switch, etc.), which is recorded as W+, W-, and the angle between the installation position and the zero point is ±92 degrees;

[0042] 3. Install a mechanical baffle on the rotating body, the baffle is centered on the zero point, and the axial angle of the baffle is 192 degrees. When the photoelectric switch is blocked by the block, its signal is 1, and the signal is 0 when it is not blocked;

[0043] 4. When crossing zero, the electronic control system conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com