Stepping motor automobile instrument pointer return-to-zero method based on counter electromotive force measurement

A technology of stepping motor and counter electromotive force, which is applied in the field of automobile instrumentation, can solve the problems of large resource occupation, occupancy, and the problem of pointer zeroing has not been properly solved, and achieves the effect of small pointer jitter and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

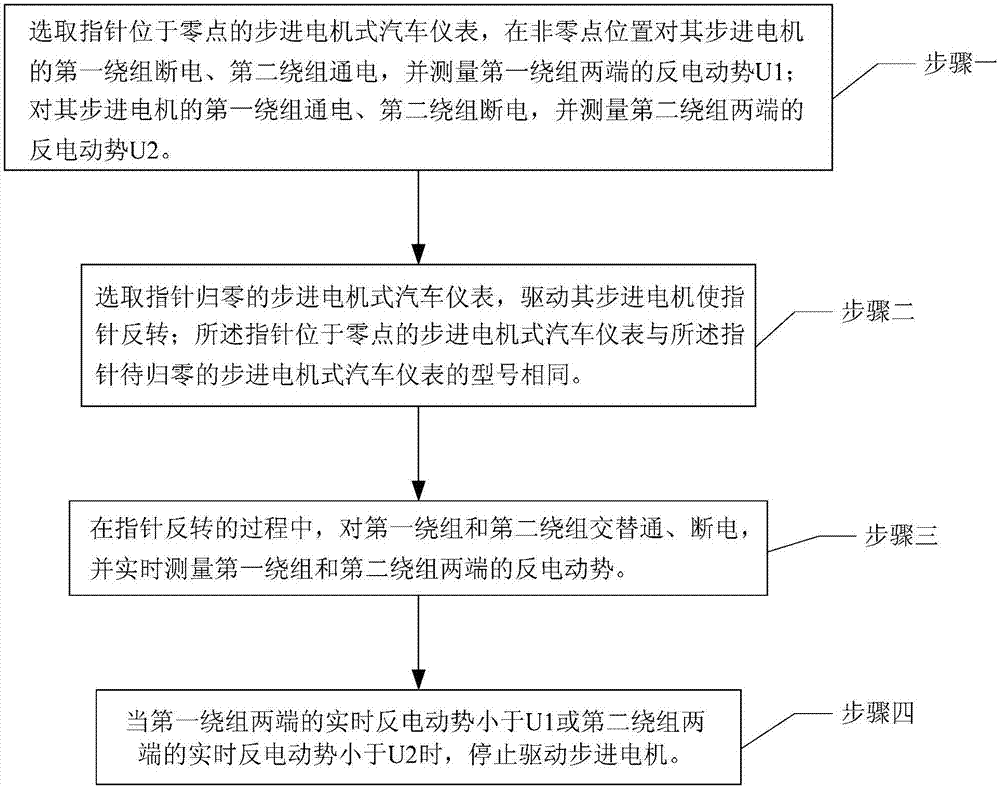

[0020] Embodiment one: combine below figure 1 This embodiment will be described in detail. The pointer zeroing method of the stepping motor type automobile meter based on back electromotive force measurement described in this embodiment includes:

[0021] Step 1. Select a stepper motor type automobile meter with the pointer at the zero point, power off the first winding of the stepper motor at a non-zero position, energize the second winding, and measure the counter electromotive force U1 at both ends of the first winding;

[0022] Power on the first winding of the stepper motor, de-energize the second winding, and measure the back electromotive force U2 at both ends of the second winding;

[0023] Step 2. Select the stepper motor type automotive instrument whose pointer is to be reset to zero, and drive its stepper motor to reverse the pointer;

[0024] The type of the stepping motor type automobile instrument whose pointer is at zero point is the same as the type of the st...

Embodiment 2

[0027] Embodiment 2: This embodiment is a further description of the pointer reset method of the stepping motor type automobile instrument based on the back electromotive force measurement described in the first embodiment.

[0028] According to the pointer reset method of the stepping motor type automobile instrument based on the back electromotive force measurement described in the present embodiment, the first winding is turned on and off every time and the second winding is turned on and off every time. The period of the received drive pulse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com