Zero-debugging method of sensor for main control valve of steering engine actuator

A sensor and actuator technology, which is applied in the field of improvement of the method of zero adjustment of the main control valve sensor of the steering gear actuator, can solve the problems of rework, out-of-tolerance consistency of the output values of the four channels of the sensor, assembly and debugging of the steering gear actuator Efficiency decline and other problems, to achieve the effect of improving assembly and debugging efficiency and improving assembly and debugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

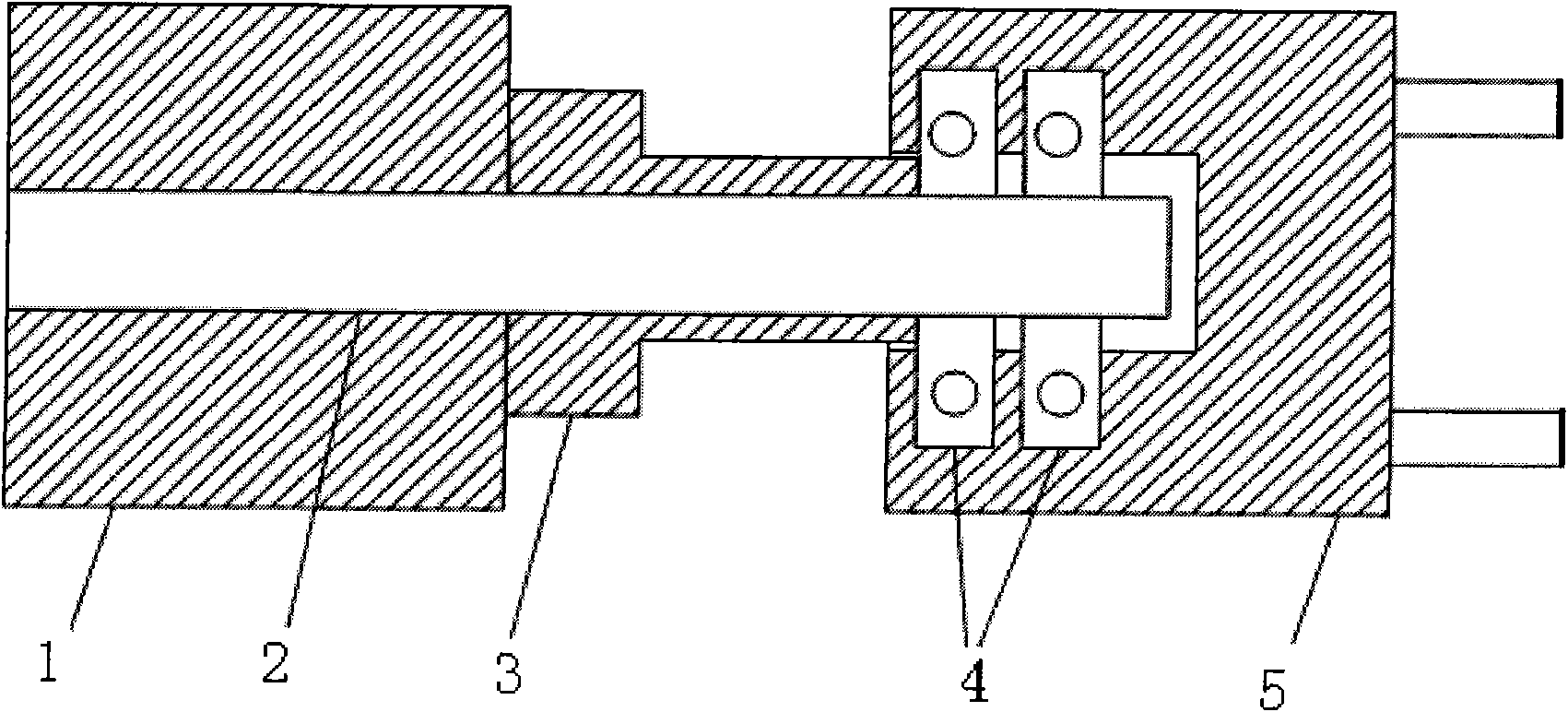

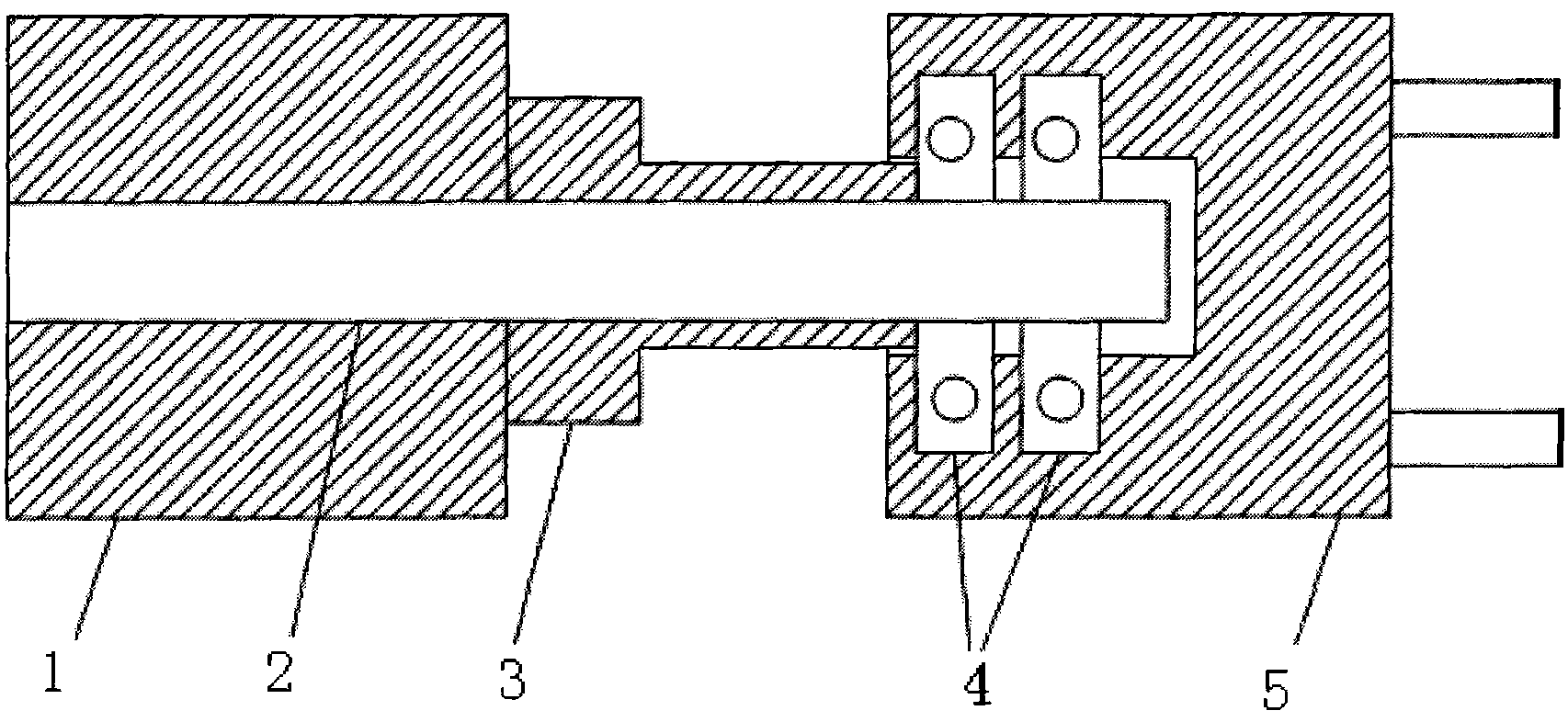

[0023] The outer diameter of the flexible rod 2 is d = 4764.2 μm, the sensor bushing 3D = 4766.5 μm, D-d = 2.3 μm. Use step 2 to rotate the flexible rod 2 one circle, measure the variation Δt1 of the output values of the four channels of the sensor, Δt1=A=B=C=D=26 μm; continue to adjust the angle of the sensor bushing 3; remove the sensor 5, Rotate the sensor bushing 3 clockwise by 90°, and then reinstall the sensor 5; rotate the flexible rod 2 once, measure the variation Δt2 of the output values of the four channels of the sensor, Δt2=A=B=C=D=18μm, and continue to adjust The angle of the sensor bushing 3; remove the sensor 5, continue to rotate the sensor bushing 3 90° clockwise, and then reinstall the sensor 5; rotate the flexible rod 2 one circle, and measure the variation of the output value of the four channels of the sensor Δt3 , Δt3=A=B=C=D=14 μm≤15 μm. Then the zero position debugging of the sensor 5 was successfully completed.

Embodiment 2

[0025] The outer diameter of the flexible rod 2 is d = 4764.2 μm, the sensor bushing 3D = 4765.8 μm, D-d = 1.6 μm. Use step 2 to rotate the flexible rod 2 one circle, measure the variation Δt1 of the output values of the four channels of the sensor, Δt1=A=B=C=D=17 μm; continue to adjust the angle of the sensor bushing 3; remove the sensor 5, Rotate the sensor bushing 3 clockwise by 90°, and then reinstall the sensor 5; rotate the flexible rod 2 once, and measure the variation Δt2 of the output values of the four channels of the sensor, Δt2=A=B=C=D=11μm≤15μm, The zero position debugging of the sensor 5 is completed.

Embodiment 3

[0027] The outer diameter of the flexible rod 2 is d = 4764.5 μm, the sensor bushing 3D = 4765.7 μm, D-d = 1.2. Use step 2 to rotate the flexible rod 2 one circle, measure the variation Δt1 of the output values of the four channels of the sensor, Δt1=A=B=C=D=11μm≤15μm, and the sensor 5 has been adjusted for zero position.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com