Zero adjustment device for rotary encoders and application method thereof

A rotary encoder and zero-position adjustment technology, which is applied in the direction of operation through the zero-adjustment method, can solve the problems of difficulty in controlling the accuracy, the encoder shaft stops at the zero position, etc., and achieves the effect of compact structure, stable transmission and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The installation method of the rotary encoder on the automatic control mechanism: the hollow rotating shaft 4-1 of the rotary encoder is connected to the rotating shaft 1 of the automatic control mechanism under test; the housing 4-3 of the rotary encoder 4 passes through an elastic bracket 4 -2 is arranged on the mounting plate 2 of the automatic control mechanism under test.

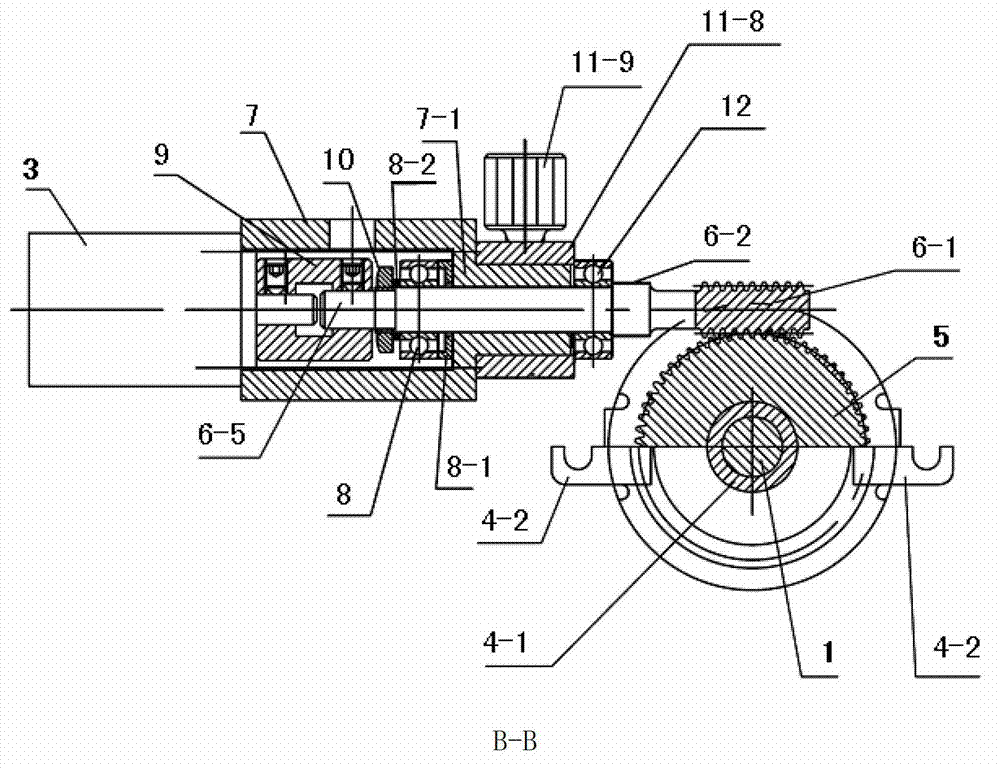

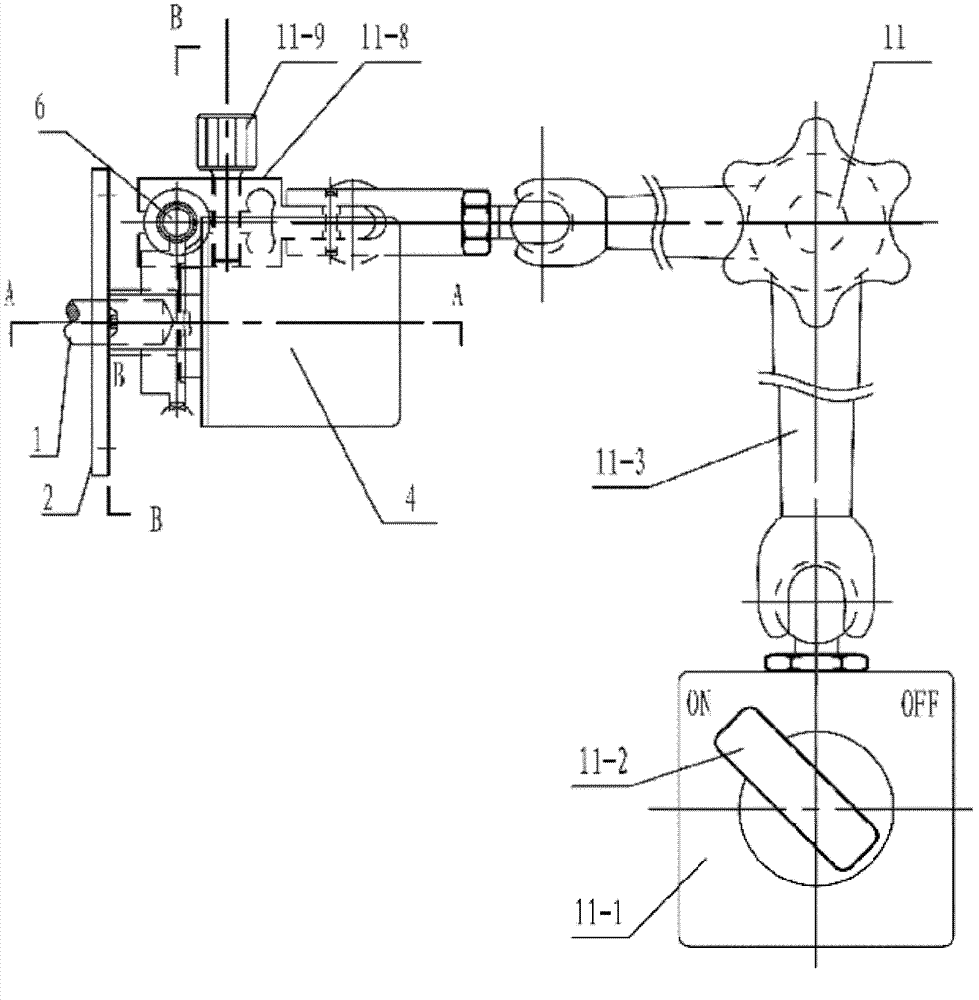

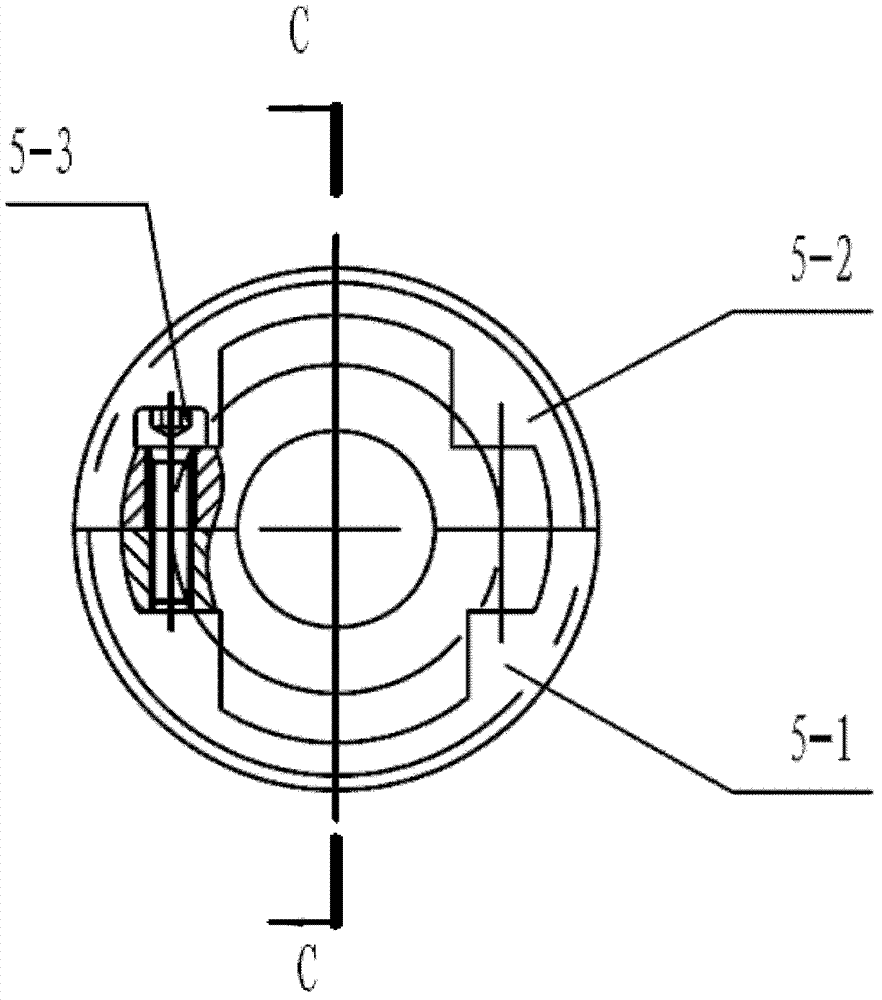

[0036] Such as Figure 1-5 The zero adjustment device of the rotary encoder comprises: an encoder acquisition card for connecting the signal output end of the rotary encoder 4 of an automatic control mechanism, a computer connected to the encoder acquisition card, an electronic handwheel, and the electronic handwheel The stepper motor driver connected to the signal output end of the wheel, the stepper motor connected to the stepper motor driver, the helical gear 5, the cylindrical worm 6 and the universal magnetic gauge base assembly 11. The stepper motor driver is adapted to drive the stepper ...

Embodiment 2

[0048] The method for using the zero position adjustment device of the rotary encoder in the above-mentioned embodiment 1 includes:

[0049] First determine the approximate position of the zero point of the rotary encoder. The signal output end of the rotary encoder is connected with the encoder acquisition card, and the encoder acquisition card is inserted into the expansion slot of the computer; the user holds the encoder housing with one hand, and slowly rotates the hollow shaft of the rotary encoder with the other hand, and the computer real-time Read the output of the rotary encoder through the encoder acquisition card and display it. At this time, the software is set to read the zero signal and display it at the zero position and stop reading the zero signal. When the user observes the computer display after the zero position Stop rotating the hollow shaft of the rotary encoder. Due to the lag of human reaction, the rotary encoder generally cannot stop exactly at the zer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com