Large composite sieving machine for old and decayed garbage

A sieving machine and garbage technology, which is applied in the direction of screening, solid separation, and separation of solids from solids with airflow, etc. It can solve the problems of low sorting rate, manual separation, and insufficient sorting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

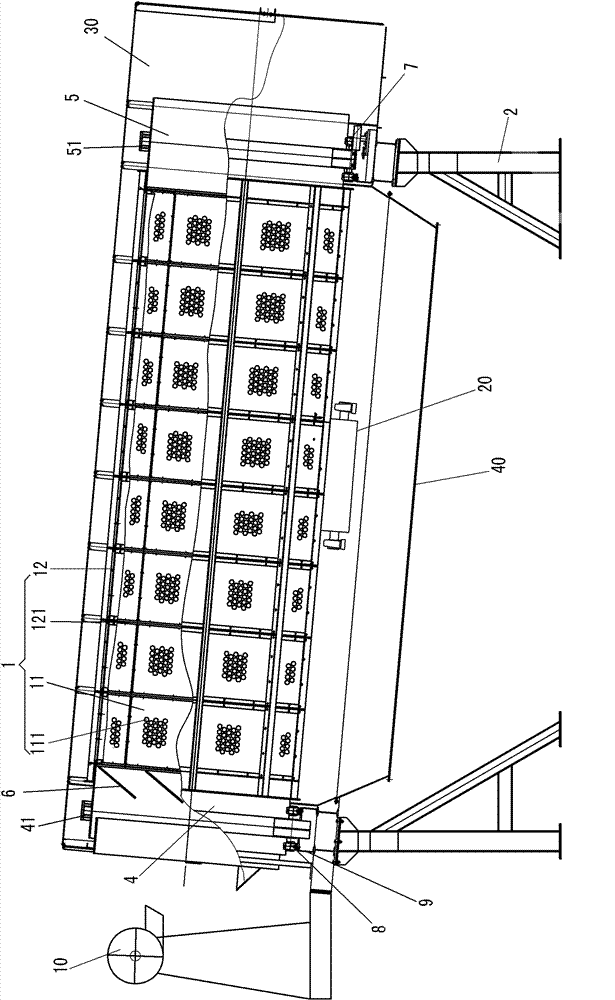

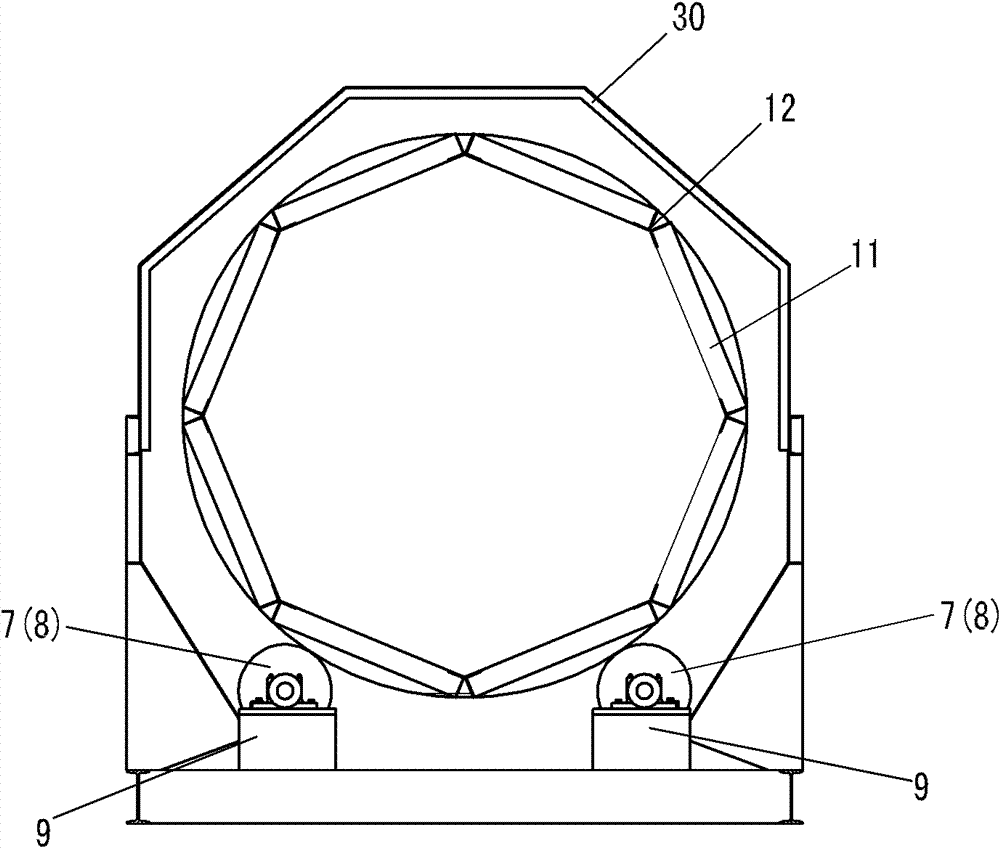

[0015] see figure 1 , figure 2 As shown, the old garbage large-scale composite screening machine of the present invention includes a screen body 1, a bracket 2, a transmission mechanism and a fan 10;

[0016] The sieve body 1 is placed horizontally and inclined to the horizontal plane, the left end of the sieve body 1 is higher than the right end, the left and right ends of the sieve body 1 are respectively provided with a cylindrical left end frame 4 and a right end frame 5, and the left end frame 4 and the right end frame 5 are respectively provided with There is a protruding first raceway 41 and a second raceway 51, the left port of the left end frame 4 is the feed inlet, and the right port of the right end frame 5 is the discharge port;

[0017] The transmission mechanism includes two driving friction wheels 7 and two driven friction wheels 8 driven by the motor. The first raceway 41 and the second raceway 51 of the left end frame 4 and the right end frame 5 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com