Coulomb friction damped disc brake caliper bracket

A technology of disc brakes and Coulomb friction, applied in the direction of brake types, brake components, and axial brakes, etc., can solve problems such as interface erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

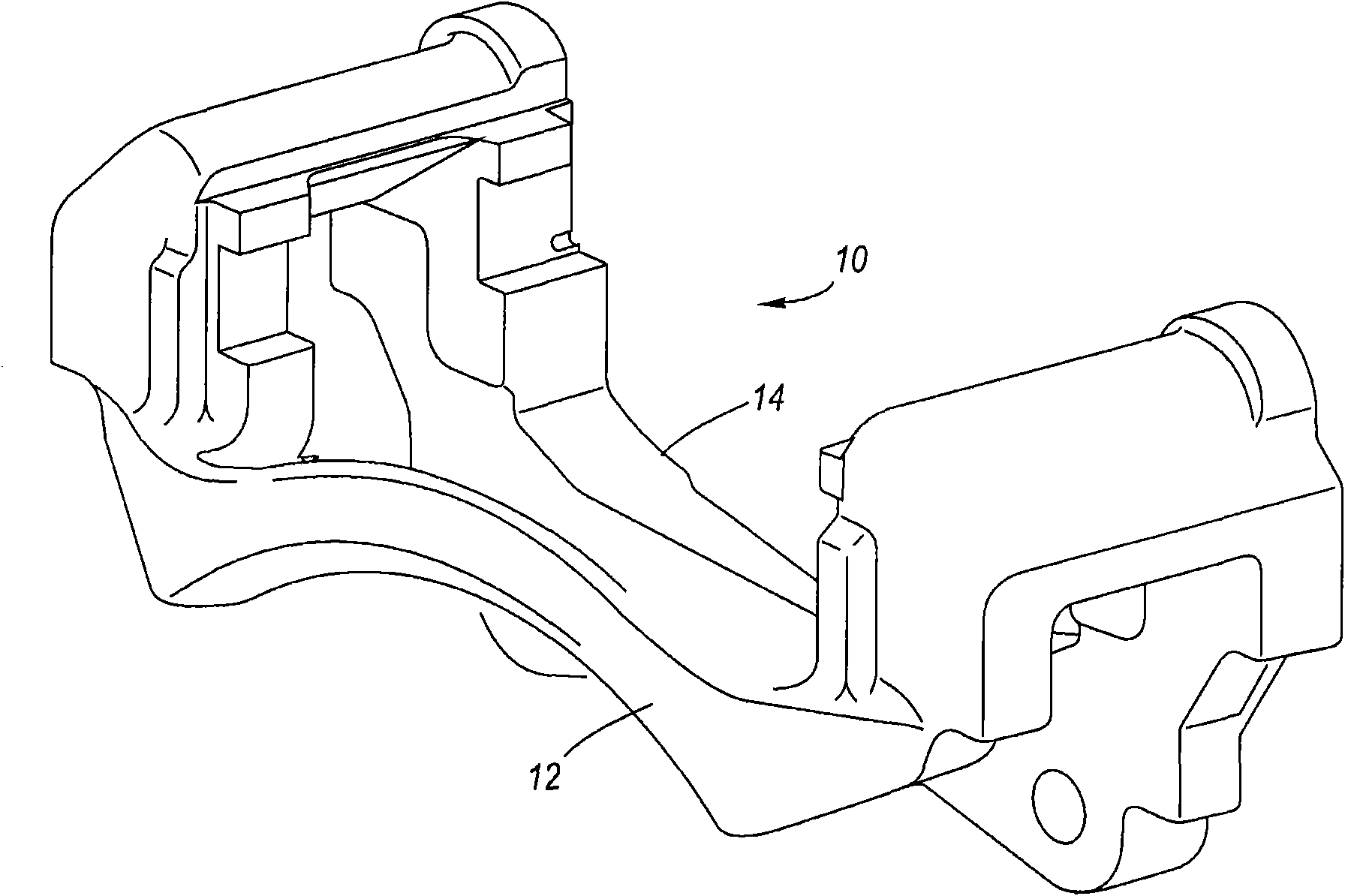

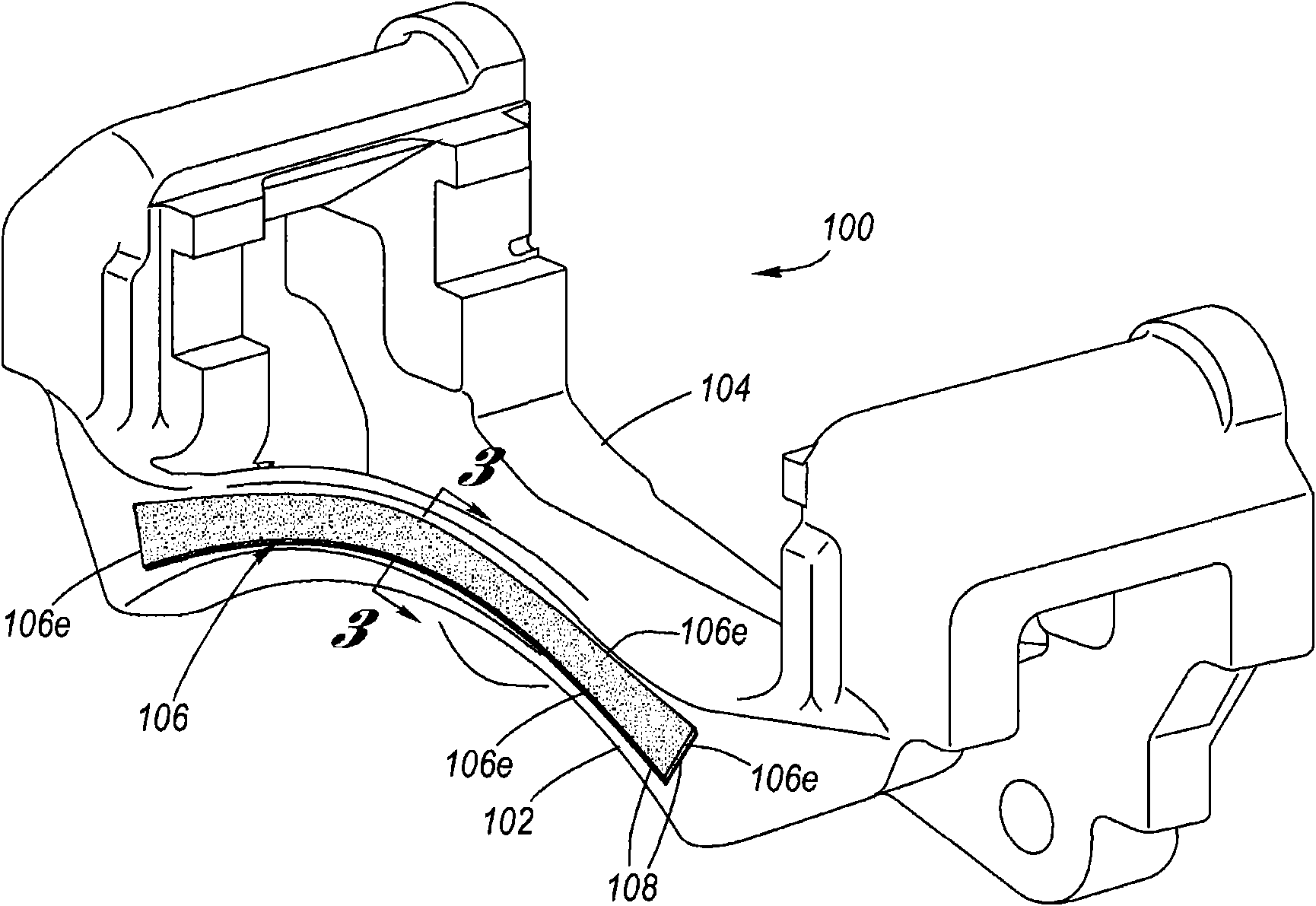

[0040] Referring now to the accompanying drawings, Figure 2 to Figure 5 Various aspects of an example of a disc brake caliper mount 100 for Coulomb friction damping for motor vehicle disc brake applications are shown.

[0041] In the disc brake calipers of the disc brake angle, figure 2 with image 3 A non-limiting example of a Coulomb friction damped disc brake caliper bracket 100 is shown, which can be used with the figure 2 The one shown is shaped differently, including an outer tie rod 102 and an inner tie rod 104 .

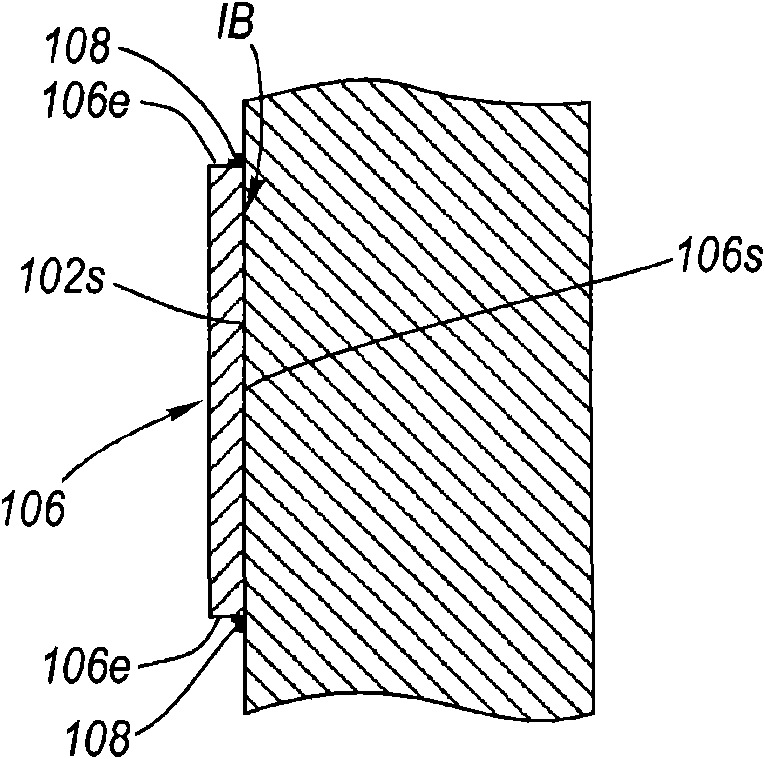

[0042] for in figure 2 In the example shown in , the Coulomb friction bar 106 is peripherally welded 108 to the outer surface 102s of the outer tie bar 102 . The term "peripheral welding" refers to the continuous welding of the Coulomb friction bar 106 to the outer surface 102s of the outer tie rod 102 as a closed loop or path along the peripheral edge 106e of the Coulomb friction bar 102 (see Figure 4 ), wherein the metal fusion caused by the perimete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com