Clapper switching shower

一种花洒、切换机构的技术,应用在喷射装置、阀细节、发动机元件等方向,能够解决操作不便等问题,达到占用空间小、布局合理、高压切换灵活的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] first preferred embodiment

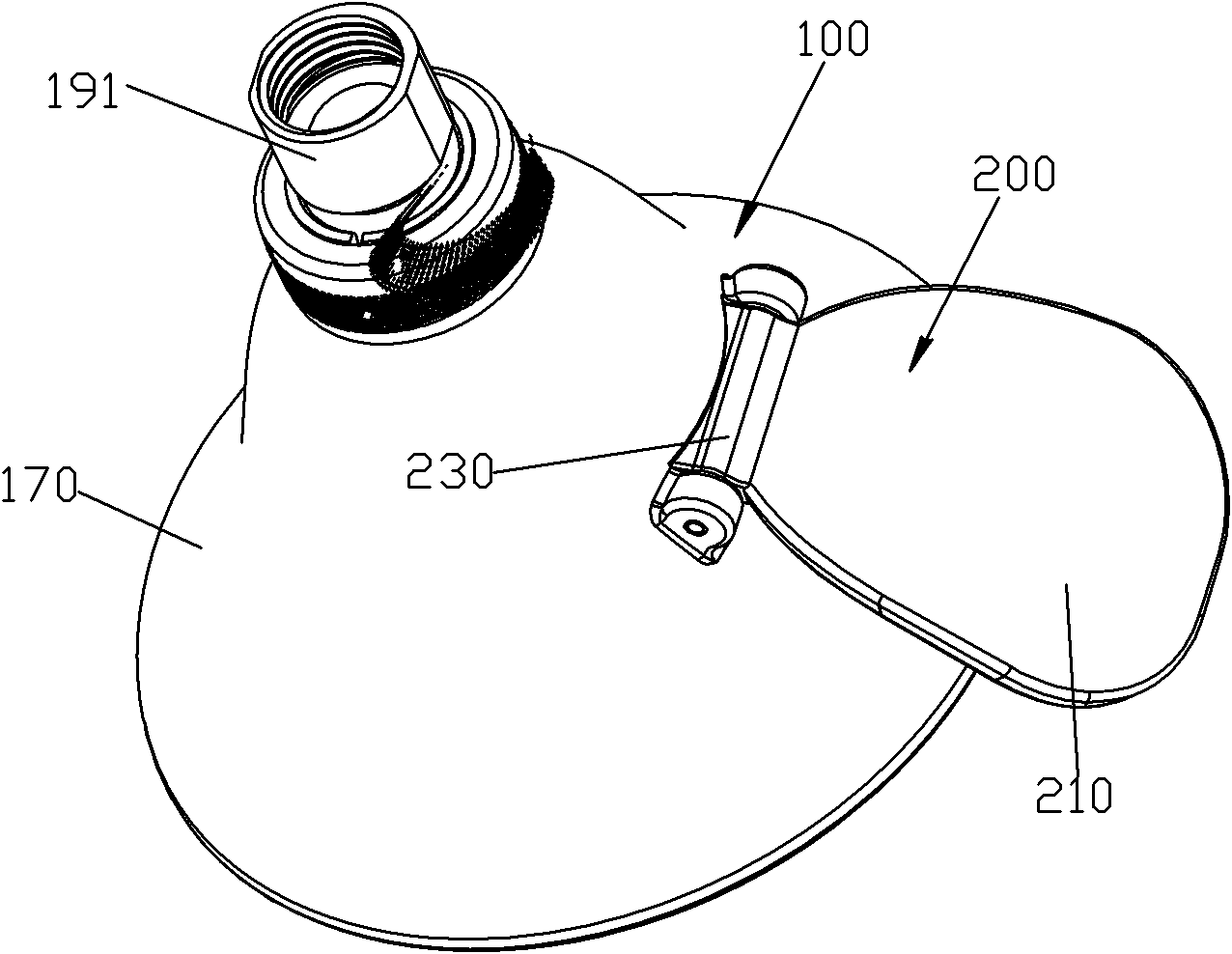

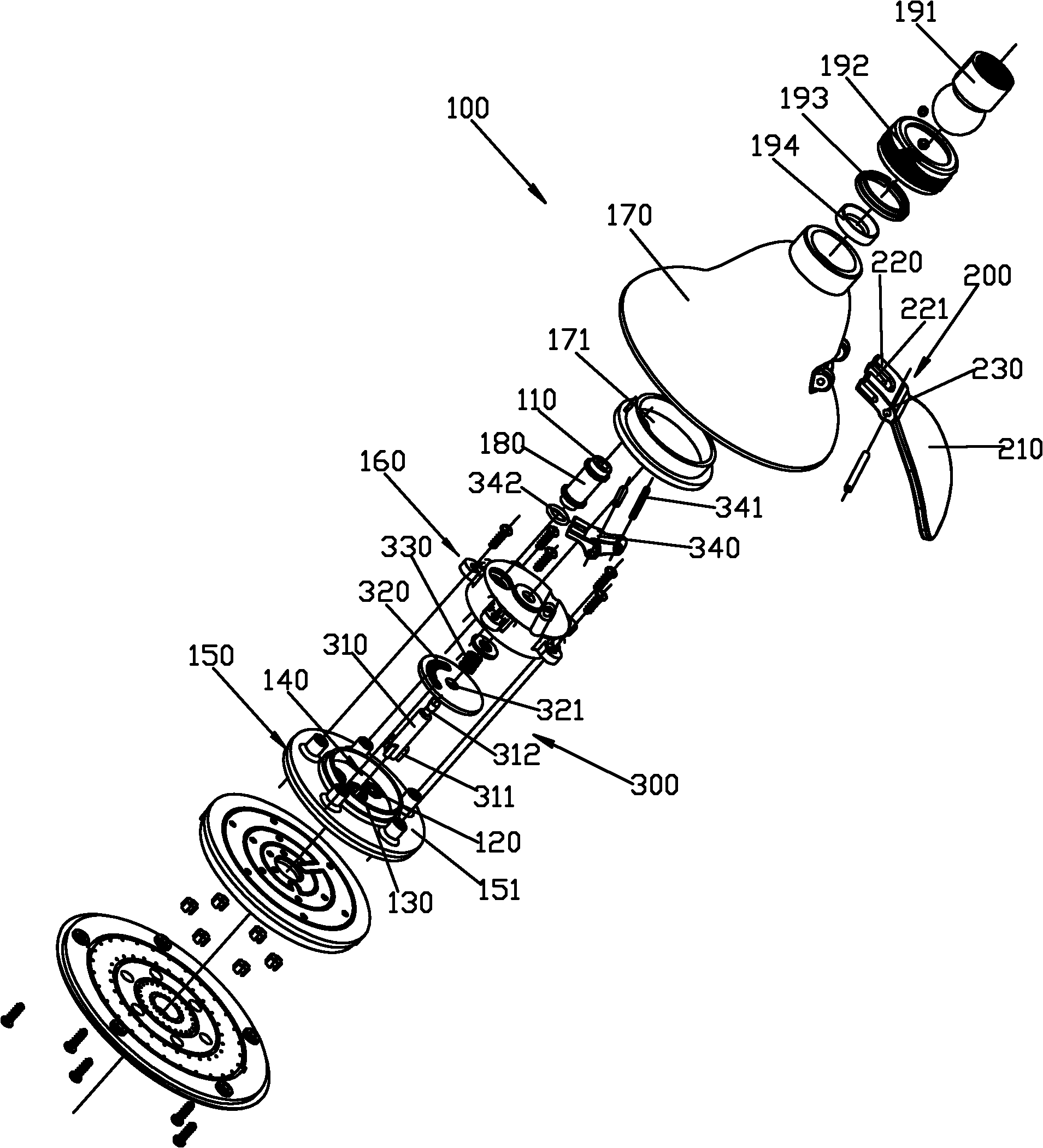

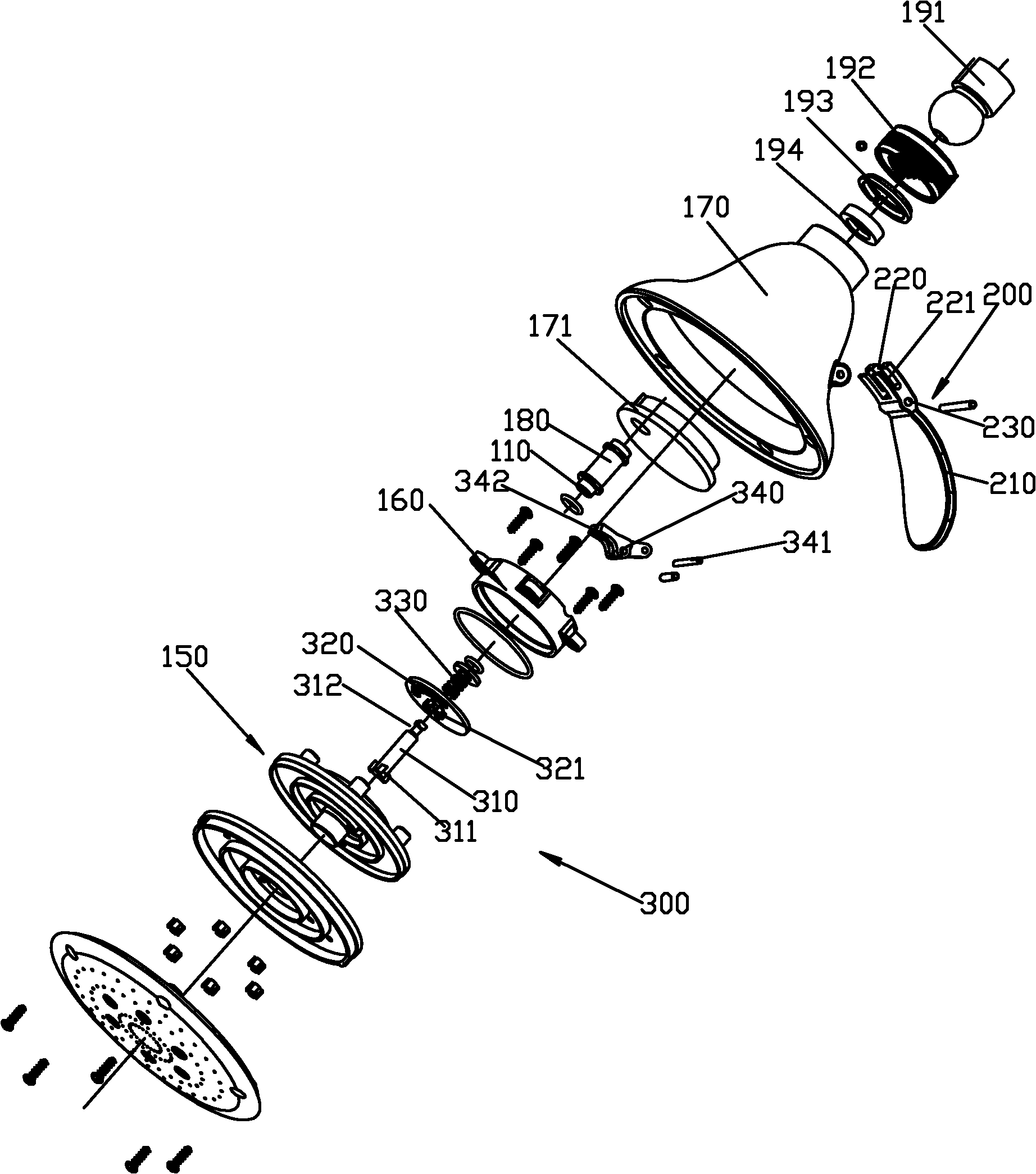

[0066] Please check Figure 1 to Figure 8 , a clapper switching shower, which includes a fixed unit 100, an operating panel 200 and a switching mechanism 300.

[0067] The fixing unit 100 includes a water outlet terminal 150 , an upper cover 160 , a casing 170 and a water conduit 180 .

[0068] The water outlet terminal 150 is provided with three water outlet functions, and each water outlet function corresponds to a water outlet channel 120 , and the ports of the multiple water outlet channels 120 are arranged in a ring on the switching surface 151 of the water outlet terminal 150 .

[0069] The upper cover 160 includes a surrounding wall and a cover plate fixed on the surrounding wall, and the surrounding wall is sealingly connected with the switching surface 151 of the water outlet terminal 150 . In order to ensure the sealing performance, it is better to set a sealing ring wall on the switching surface of the water outlet terminal 150,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com