90-degree flanging pipe expander

A tube expander and flanging technology, which is applied in the field of tube expanders, can solve the problems that the degree of expansion of the tube opening cannot be reached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

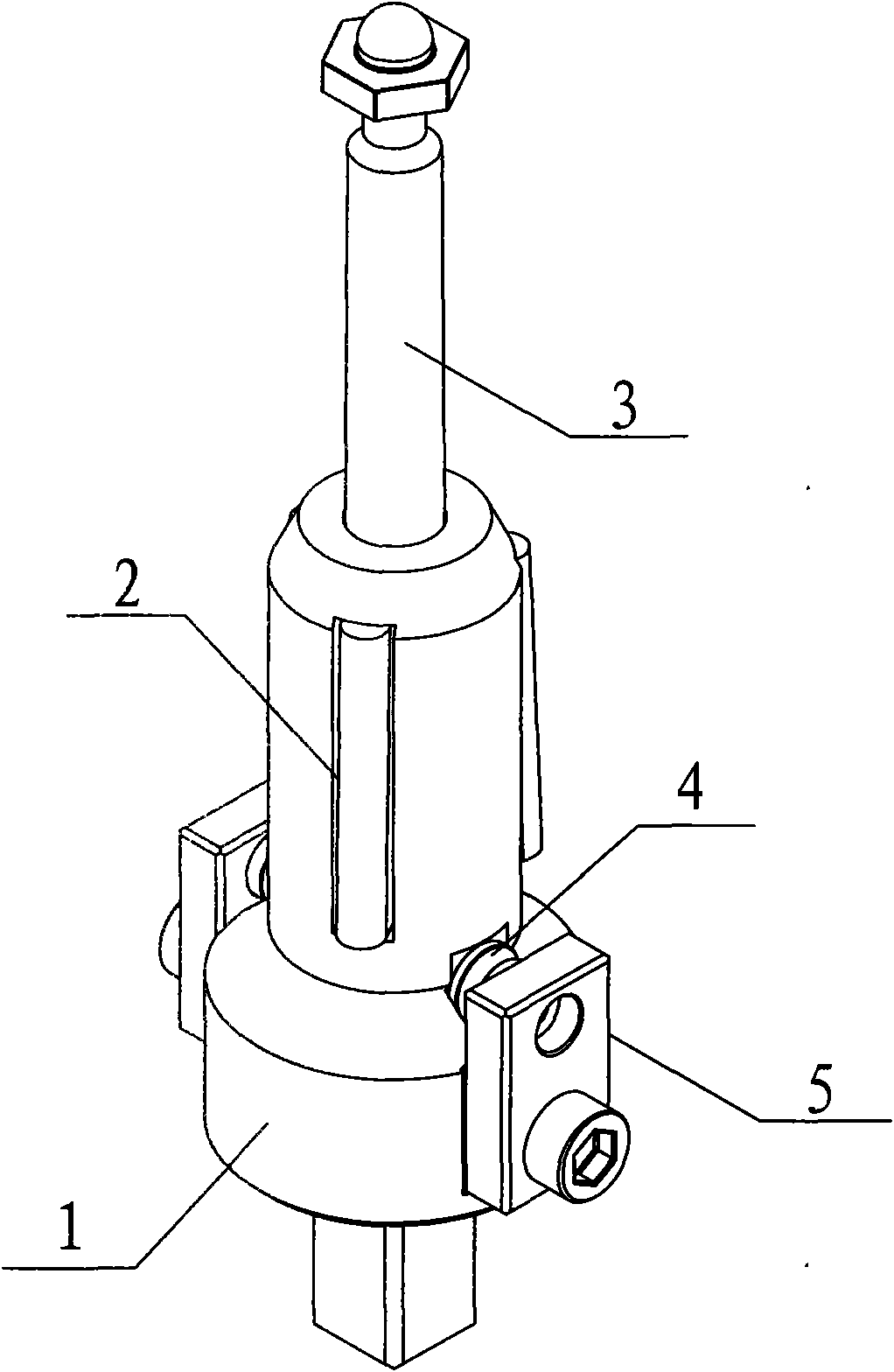

[0012] figure 1 A 90-degree flanging tube expander is shown, including an expansion shell 1, an expansion bead 2 installed inside the expansion shell 1, and an expansion rod 3 passing through the expansion shell 1, which is connected with the expansion bead 2 in the middle of the expansion shell 1 There is a bead 4 at the position, and the bead 4 is connected to the expansion shell 1 by a fixing bracket 5 through a nut. The fixing bracket 5 can prevent the bead 4 from being deformed and dislocated due to the extrusion force.

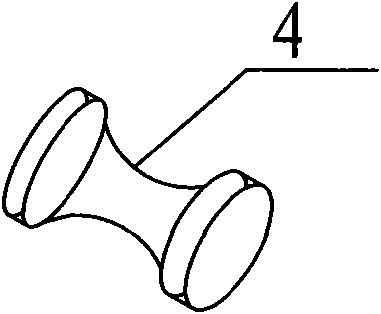

[0013] figure 2 The shape of the shown bead 4 is concave in the middle, and the edge of the nozzle will be bent to the edge along the concave track of the bead 4, so that the nozzle can be expanded into an arc of 90 degrees.

[0014] When expanding the inner and outer diameters of the pipe, push the expansion rod 3, drive the expansion bead 2, and screw into the expansion shell 1. When the edge of the pipe reaches the bead, the fixed bracket 5 can prev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap