Yarn tension device for a double-strand twisting spindle

一种纱线制动器、倍捻锭子的技术,应用在纺织品和造纸等方向,能够解决强纱线张力增加、纱线断裂等问题,达到高纱线张力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

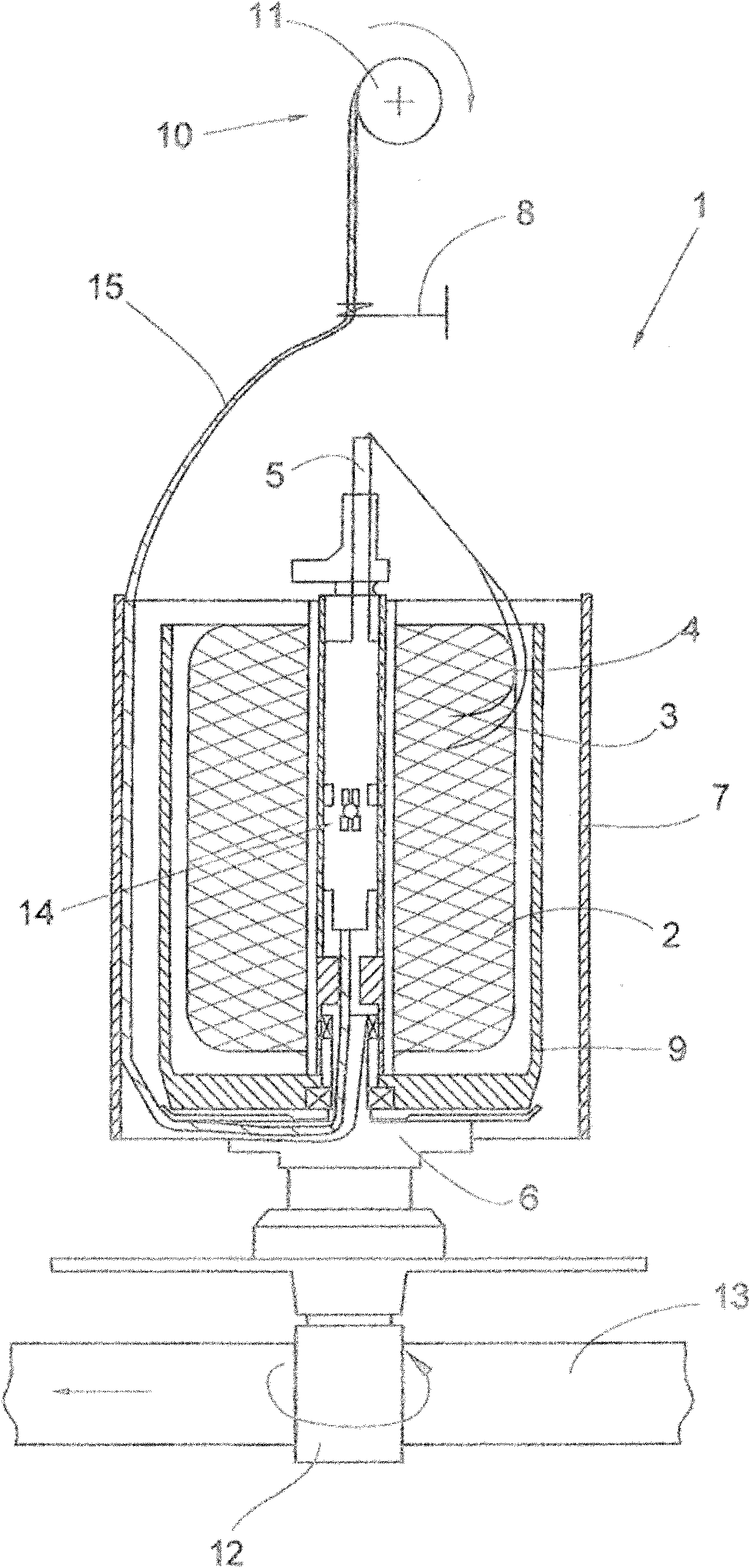

[0032] figure 1 The two-for-one twisting spindle, which is designated as a whole with the reference numeral 1 , is shown schematically in partial section. One or more yarns are arranged to be twisted by means of such two-for-one twisting spindles 1 . This twisting is provided to improve the quality of the yarn / counts, for example in terms of tear strength, and thus further improve the processability for subsequent processes such as weaving, weaving, knotting etc.

[0033] In this case the actual double twisting process is performed as follows:

[0034] like figure 1As shown in the embodiment of , the yarns 3 and 4 are for example unwound from a supply bobbin 2 mounted in a stationary protective tank 9 and introduced from above into the hollow shaft 5 of the two-for-one twisting spindle 1 . When passing through the hollow shaft 5, the yarns 3 and 4 are twisted by the rotatably mounted spindle part 6 (which is arranged below the protective tank 9), deflected in an L-shaped ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com