Ionomer resin, resin compositions containing same and uses of both

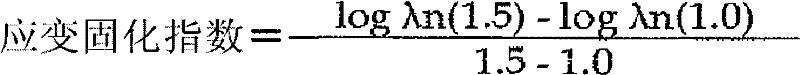

A technology of ionomer resin and resin composition, which is applied in the field of ionomer resin and resin composition containing the ionomer resin, can solve the problem of damage to the balance of mechanical properties, the decline of impact resistance, mechanical properties, and mechanical properties. Reduced strength and other problems, to improve the effect of extensional viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0151] The present invention will be described more specifically below using examples, but the present invention is not limited to these examples. In the present invention, various physical properties were measured by the following methods.

[0152] (1) Melt flow rate (MFR)

[0153] The melt flow rate (MFR) of various resin compositions is measured in accordance with ASTM D1238 when using a propylene-based polymer at a temperature of 230°C and a load of 2.16kg. When using 4-methyl-1-pentane In the case of an ethylenic polymer, the measurement was performed under conditions of a temperature of 260°C and a load of 5.0 kg.

[0154] (2) Tensile properties (tensile modulus, elongation at break)

[0155] The tensile modulus and elongation at break were obtained by performing a tensile test at 23° C. and a tensile speed of 30 mm / min by a method based on JIS K7113.

[0156] (3) Bending characteristics (bending modulus)

[0157] The flexural modulus was determined by performing a f...

Embodiment 1

[0198] Except having used the metal salt of the compounding quantity shown in Table 1 as metal salt (B), it carried out similarly to the comparative example 1, and obtained the pellet (a2) and the test piece. Using the pellets and the test piece, various physical properties were evaluated. The results are shown in Table 1.

Embodiment 2

[0200] Except having used the metal salt of the compounding quantity shown in Table 1 as metal salt (B), it carried out similarly to the comparative example 1, and obtained the pellet (a3) and the test piece. Using the pellets and the test piece, various physical properties were evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com