Ultrasonic impact treatment process for reducing residual stress of aluminium alloy box girder welded structure

A welding structure, ultrasonic impact technology, applied in the field of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

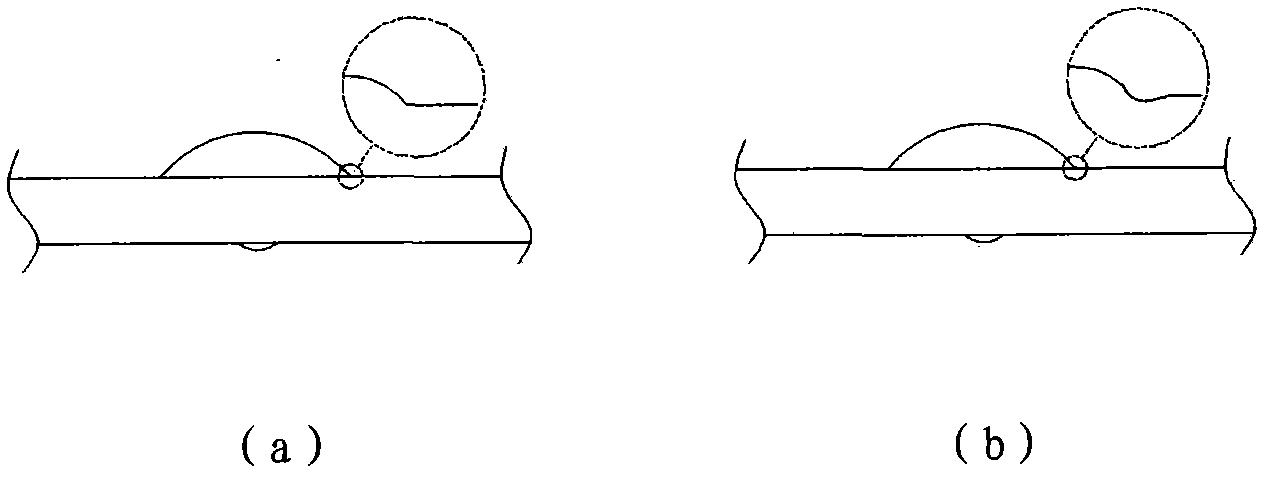

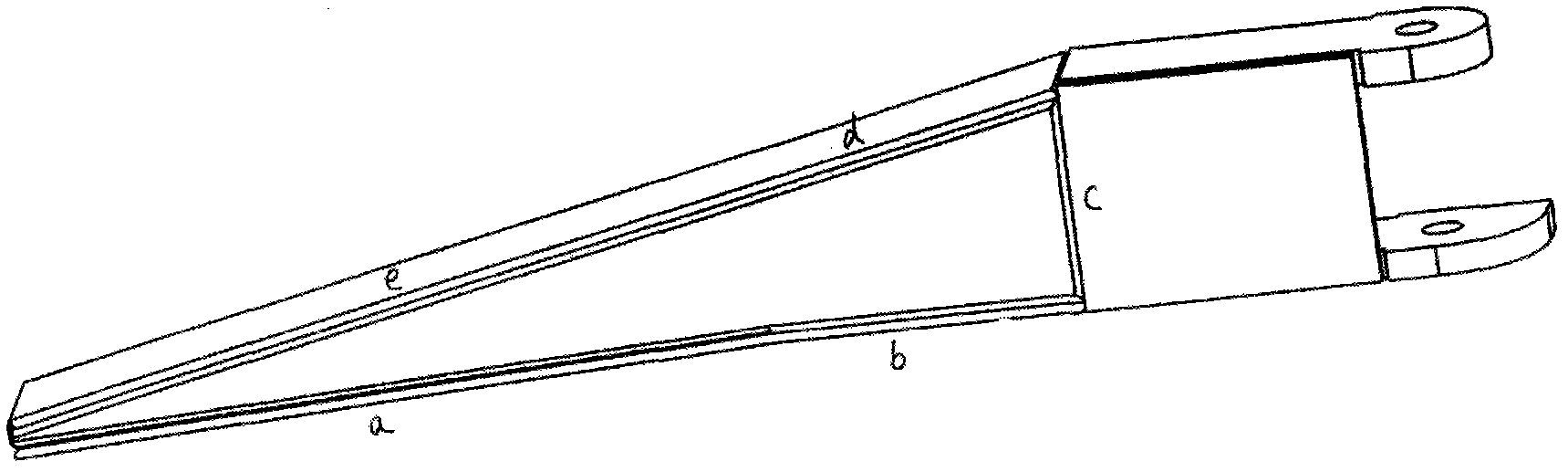

[0028] Such as figure 2 As shown, the 6mm thick aluminum alloy box girder welded structural support is subjected to ultrasonic impact treatment. It includes the following steps:

[0029] The first step: the selection of the impact head: according to the wall thickness of the aluminum alloy bracket is 6mm and the welding seam is a corner butt joint structure, so choose a double-row small impact head with a diameter of 4mm;

[0030] Step 2: Optimization of ultrasonic shock treatment process parameters: optimize the shock treatment process according to the wall thickness of the aluminum alloy bracket is 6mm, the impact speed is 1.3mm / min, the width is 10mm, the number of times is 4 times, and the impact angle is 90°;

[0031] The third step: impact treatment on the aluminum alloy box girder welded structure: use the optimized ultrasonic impact process to process the two long welds of the aluminum alloy bracket;

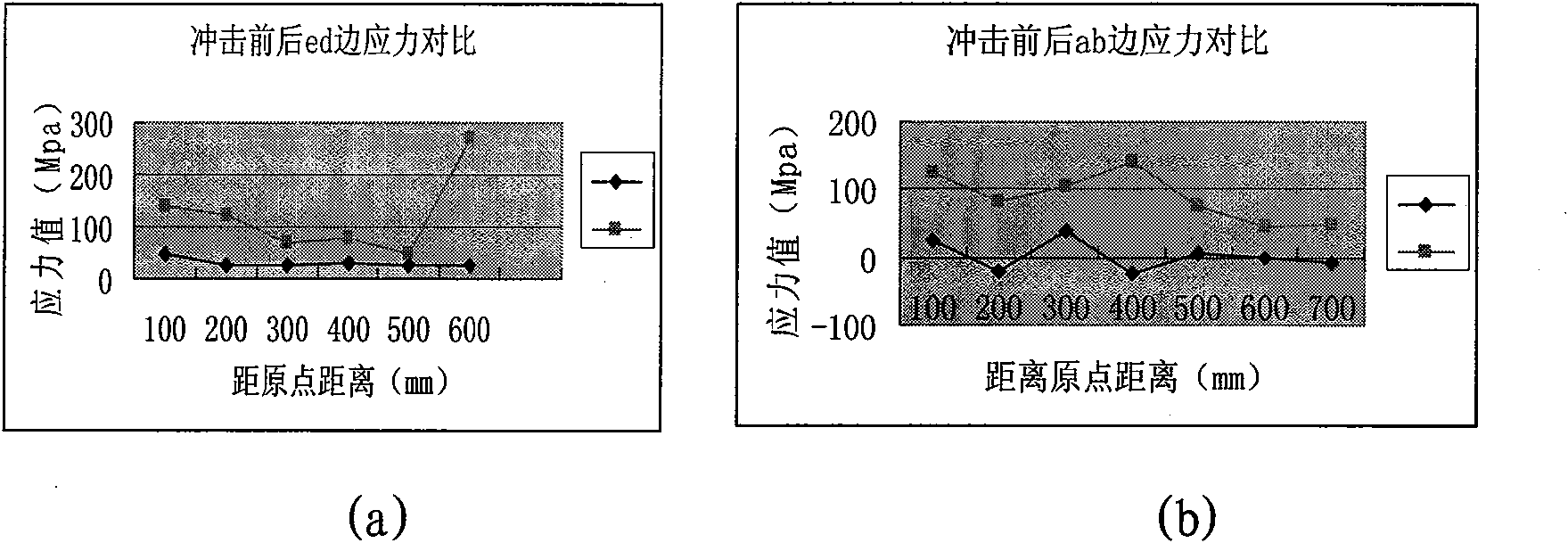

[0032] The fourth step: effect evaluation: by comparing the weld...

Embodiment 2

[0034] Ultrasonic impact treatment was performed on a 15 mm thick aluminum alloy rectangular beam. It includes the following steps:

[0035] The first step: the selection of the impact head: according to the thickness of the aluminum alloy rectangular beam is 15mm and the welding seam is a flat butt joint structure, so choose a double-row medium-sized impact head with a diameter of 6mm;

[0036] The second step: optimization of ultrasonic impact treatment process parameters: optimize the impact treatment process according to the wall thickness of the aluminum alloy rectangular beam of 15mm, the impact speed is 1.0mm / min, the width is 12mm, and the impact angle is 90°;

[0037] The third step: impact treatment on the aluminum alloy rectangular beam welded structure: use the optimized ultrasonic impact process to process the two long welds of the aluminum alloy rectangular beam;

[0038] Step 4: Effect evaluation: By comparing the welding residual stress state of the welding se...

Embodiment 3

[0040] Ultrasonic impact treatment is performed on the 25mm thick aluminum alloy box. It includes the following steps:

[0041] The first step: the selection of the impact head: according to the wall thickness of the aluminum alloy bracket is 25mm and the welding seam is a corner joint structure, so choose a single row of large impact head with a diameter of 8mm;

[0042] Step 2: Optimization of ultrasonic impact treatment process parameters: optimize the impact treatment process according to the wall thickness of the aluminum alloy box is 25mm, the impact speed is 0.8mm / min, the width is 14mm, and the impact angle is 80°~90°;

[0043] The third step: impact treatment on the welded structure of the aluminum alloy box: use the optimized ultrasonic impact process to treat the 12 long welds of the aluminum alloy box;

[0044]Step 4: Effect evaluation: By comparing the welding residual stress state of the welding seam of the aluminum alloy box welding structure that has undergone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com