System of first and second sections of a power module of a wind energy installation

A technology for power modules and wind energy equipment, applied in the field of systems consisting of the first and second sections of the power module of wind energy equipment, capable of solving problems such as connection troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

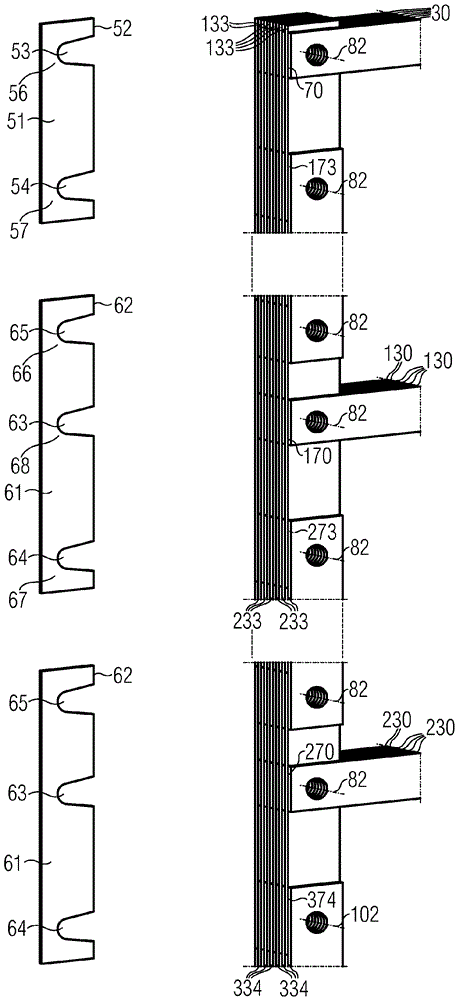

[0028] exist figure 1 The wind energy installation 1 shown schematically in the center comprises a tower 2 with a foundation 3 , a nacelle 4 mounted rotatably at the top of the tower, and a power module 5 arranged at the base of the tower.

[0029] Arranged within the nacelle 4 is a rotor with rotor blades 6 mounted rotatably about a horizontal axis, as well as a generator 7 . The rotor is set into rotation by the wind force acting on the rotor blades 6 and drives a generator 7 for generating electrical energy.

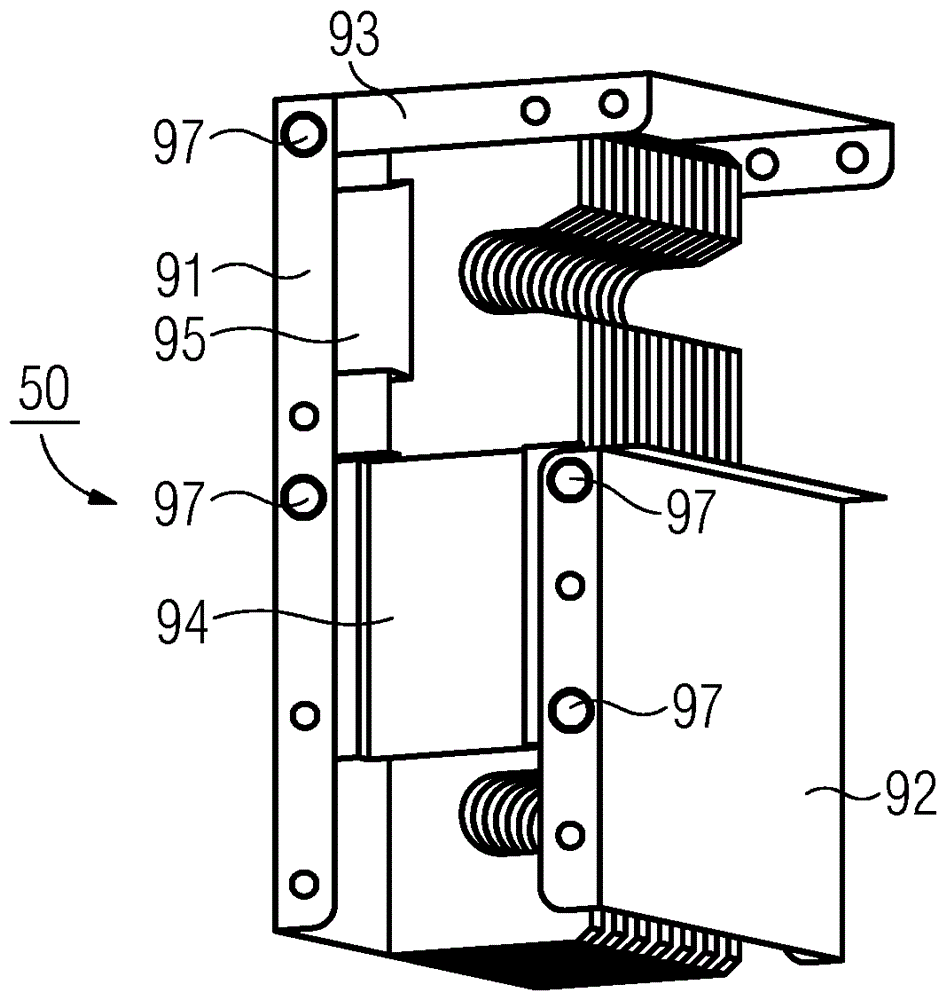

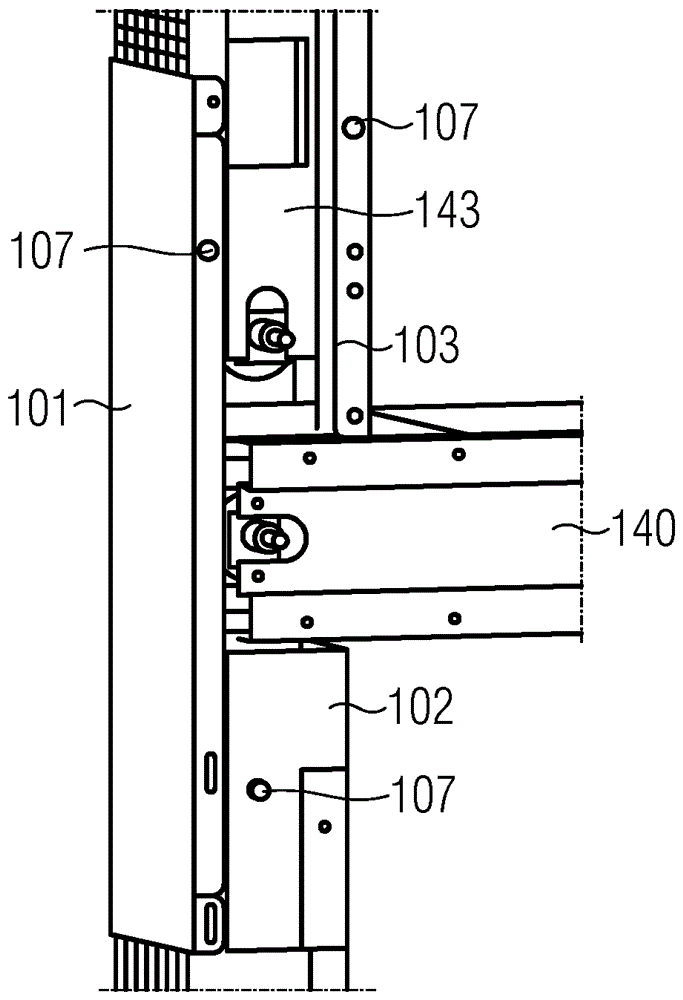

[0030] In order to transfer the electrical energy generated by the generator 7 to the power module 5 (which has different electrical units), in the inner space 8 of the tower 2 on the walls there are conductor rails 10 arranged with fixing elements 9, which are adjacent The joints of the tower sections are connected with flexible connecting rails. These conductor rails are electrically conductive and are electrically connected via cables 11 to the generator and via ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com