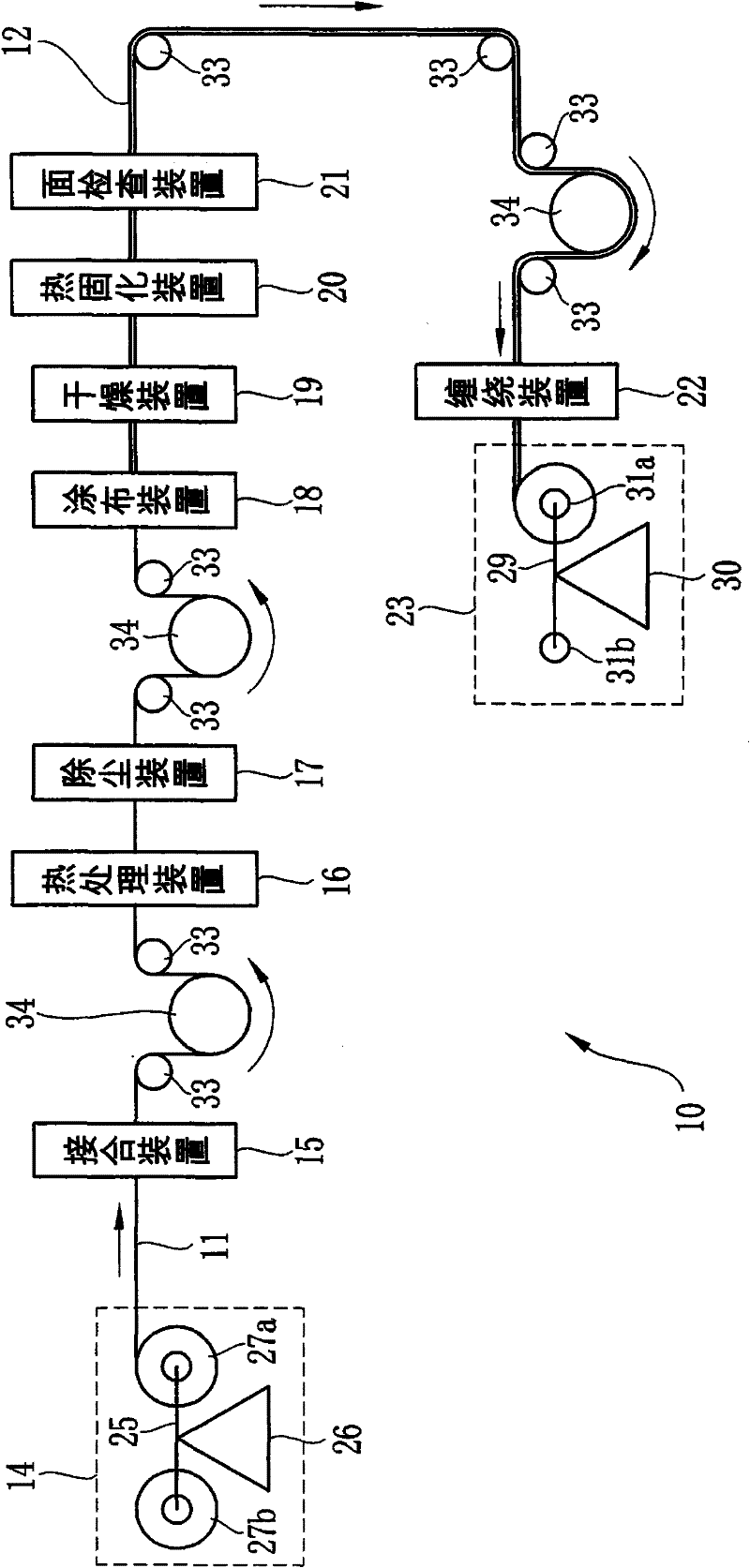

Manufacturing method of absorption roller and optical film

A manufacturing method and optical film technology, which can be used in thin material processing, transportation and packaging, and winding strips, etc., can solve problems such as adverse effects on image quality, and achieve the effect of preventing micro-scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

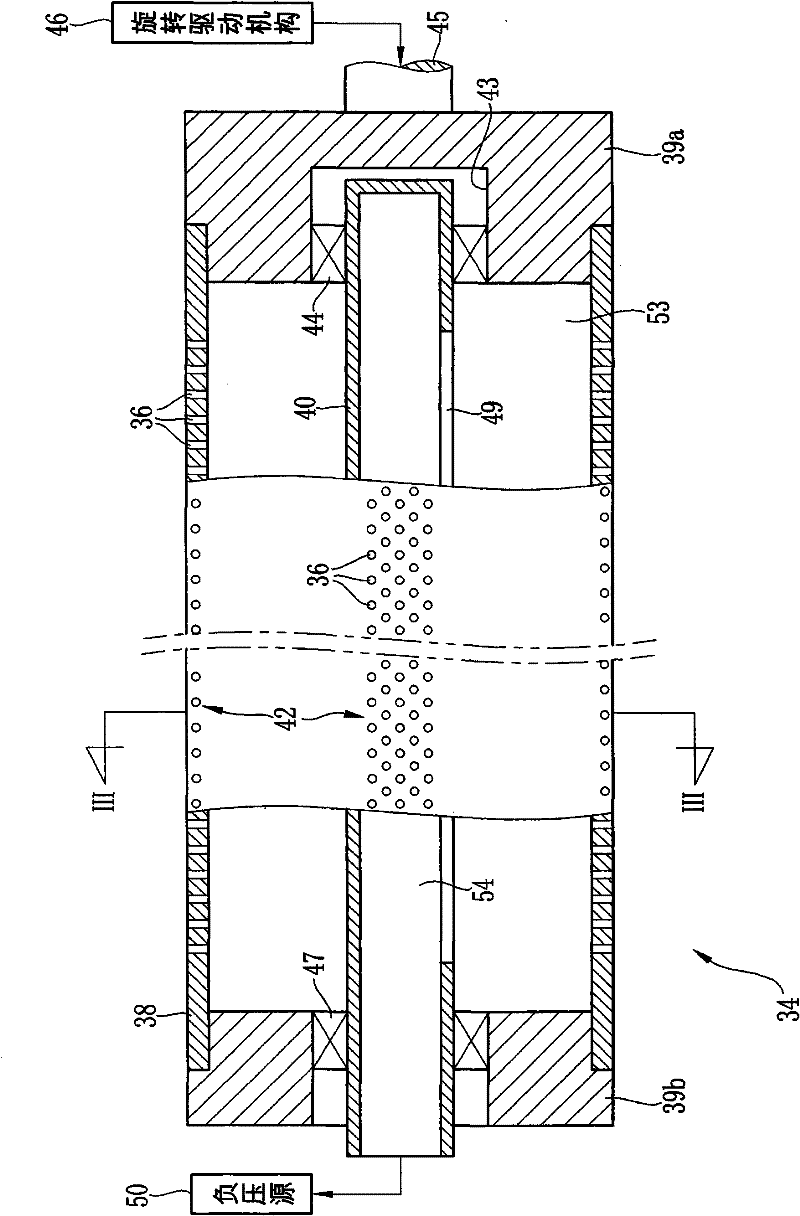

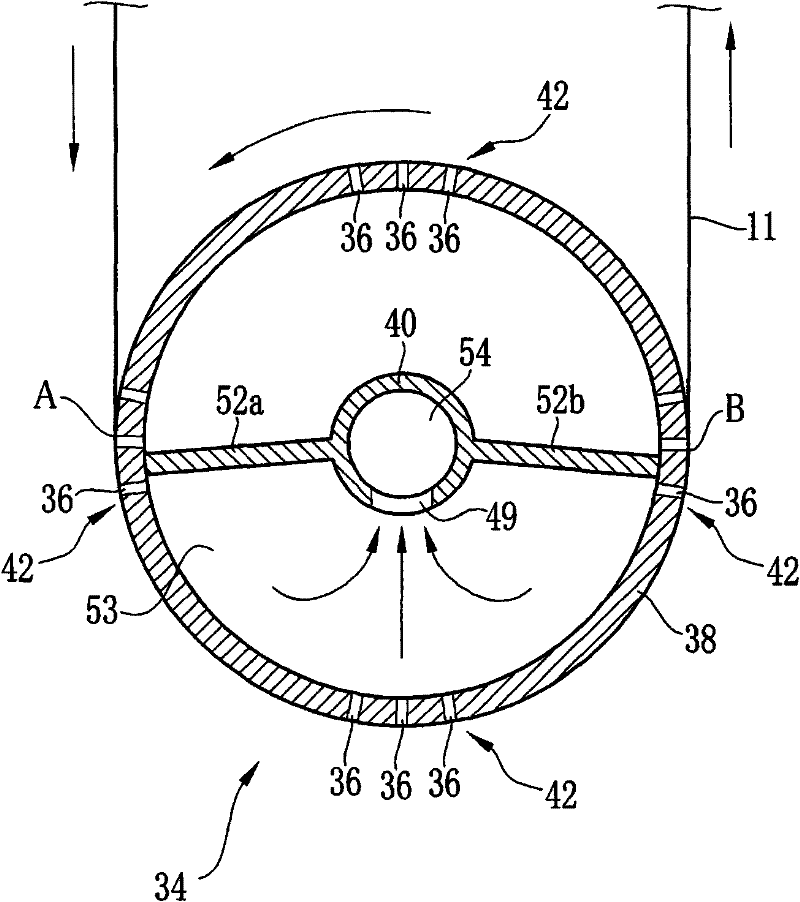

Examples

Embodiment 13

[0071] In the suction roller 34 of Example 13, the suction hole 36 , the spot facing portion 55 , and the boundary portion 56 are formed so as to satisfy the above formulas (2) and (3) except that h / D>0.2250. In the suction roller 34 of Example 14, the suction hole 36 , the spot facing portion 55 , and the boundary portion 56 are formed so as to satisfy the above formulas (1) and (2) except that D<1.5.

[0072] And, as shown in the following Table 3, in the suction rollers of Comparative Examples 1 to 3, the boundary portion 56 was not chamfered and the edge 60 was left on the boundary portion 56 (see Figure 9 ). In addition, in the suction roller of Comparative Example 1, the suction hole 36 , the spot facing portion 55 , and the boundary portion 56 are formed so as to satisfy the above formulas (1) and (3) except that L / D<1.15. The suction rollers of Comparative Example 2 and Comparative Example 3 were formed under the same conditions as in Example 1 and Example 2, respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com