Direct drive type servo knife rest

A servo tool holder and direct drive technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of affecting machining accuracy, poor accuracy, easy shock and vibration, etc., to avoid transmission errors, improve reliability and The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

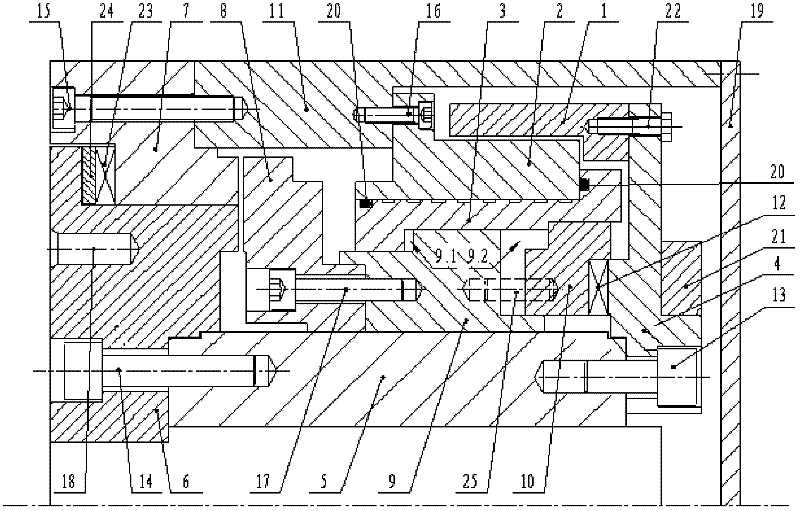

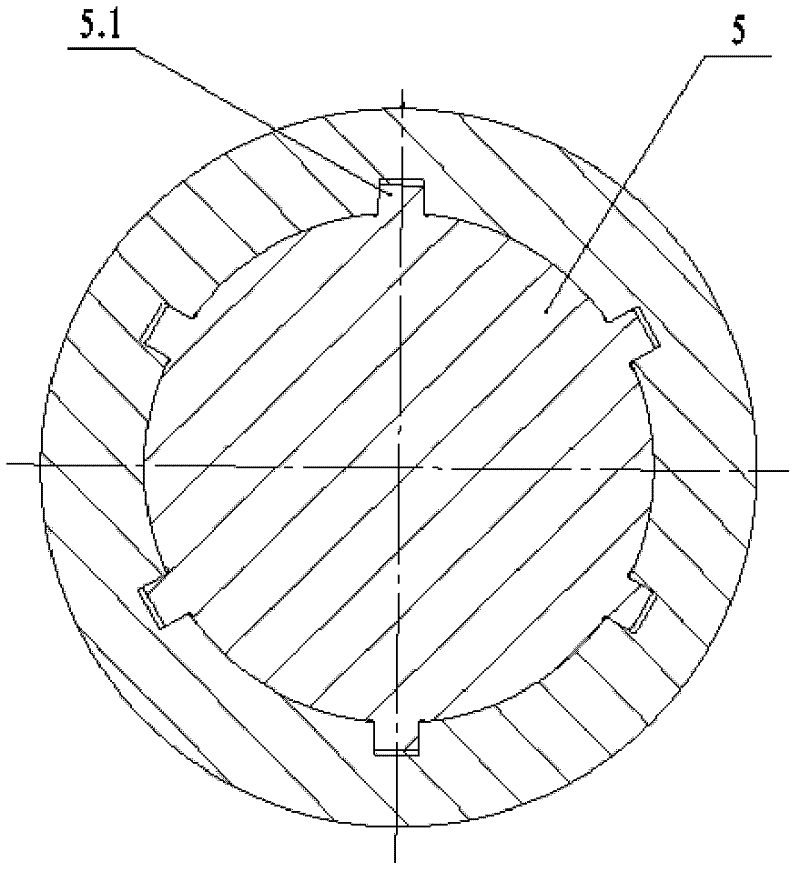

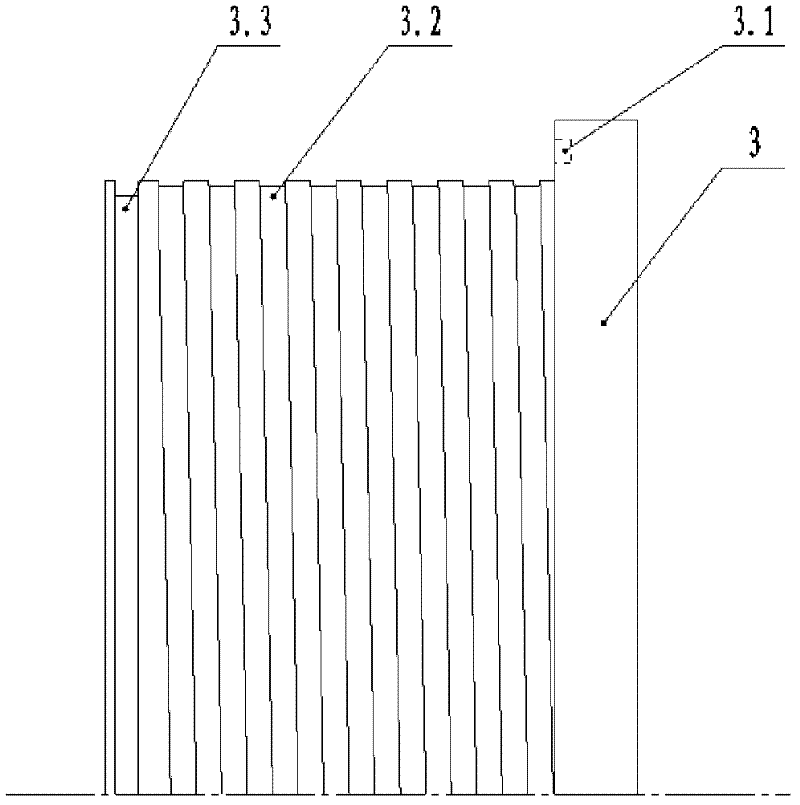

[0024] like figure 1 , figure 2 , image 3 As shown, the direct-drive servo tool post includes an outer shell 11, a torque motor, a disc connector 4, a main shaft 5, a movable toothed plate 6, a fixed toothed plate 7, and a locking toothed plate 8. The rear end of the outer shell 11 is provided with a rear End cover 19, the tool holder is directly driven by a low-speed, high-torque, outer rotor torque motor, the torque motor is located at the rear end of the tool holder, and the torque motor stator 2 passes through the bolt 16 is fixed on the outer casing 11, and the torque motor rotor 1 is fixed by bolts 22 is fixed with the disc connector 4, and the disc connector 4 passes through the bolt 13 is fixed to the rear end of the main shaft 5, and the circumferential positioning is realized through the spline 5.1 of the main shaft 5. The right end o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap