Ceramic milk bottle and production method thereof

A milk bottle and ceramic technology, which is applied in the field of milk bottles, achieves broad market prospects, slow heat conduction, and the effect of solving the volume measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

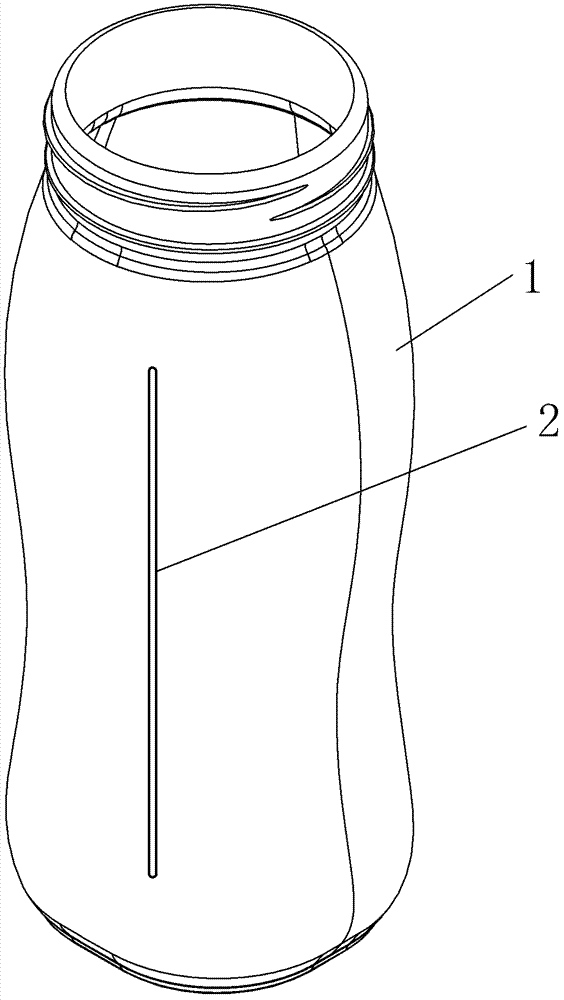

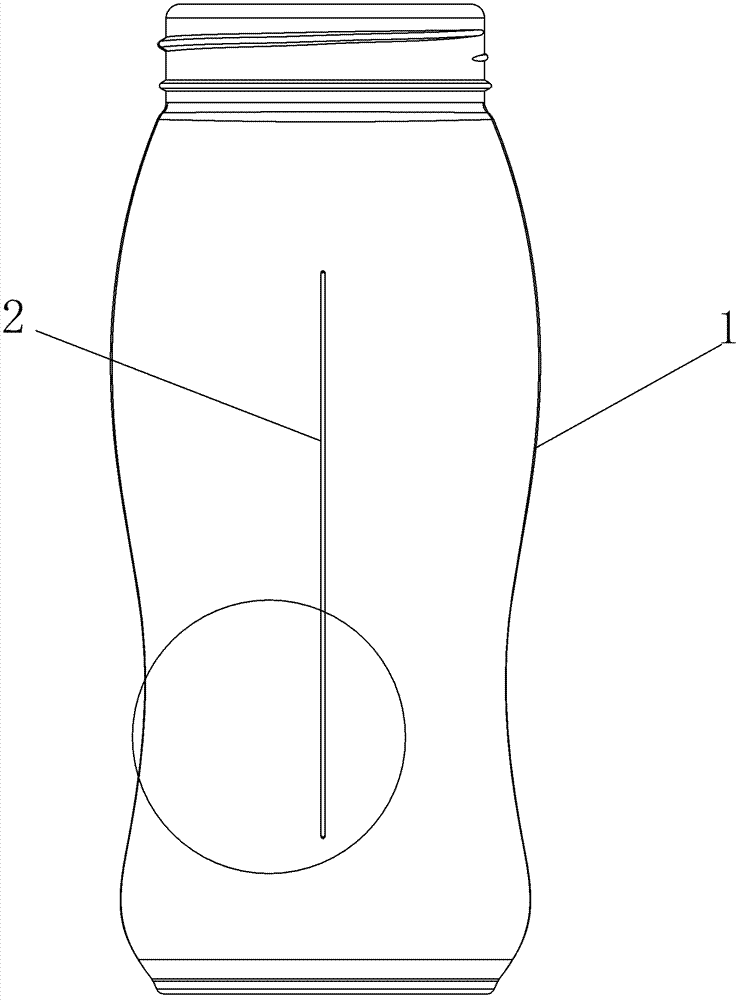

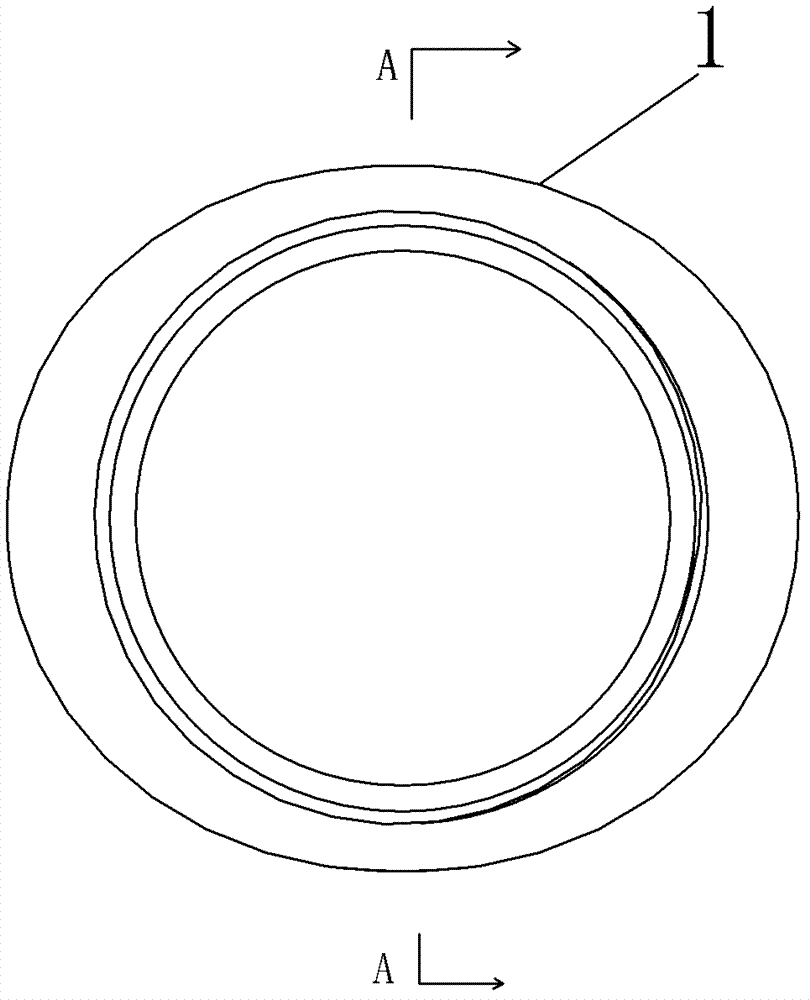

[0025] like figure 1 , figure 2 , image 3 , Figure 4 As shown, one embodiment of the present invention comprises a bottle body 1, and the bottle body 1 has an opening 2 passing through the bottle body wall 11, and a transparent glaze is filled in the opening 2 passing through the bottle body wall to form a transparent wall 3, and through the transparent wall 3 The height of the liquid in the bottle can be seen from the outside. This transparent wall 3 becomes the window for observing the liquid height inside the bottle through the outside of the bottle, if supplemented with scale, see figure 2 , the volume of the liquid inside the bottle can be easily observed. The opening 2 through the wall of the bottle can be continuous or discontinuous, and the preferred solution is that the opening 2 through the wall of the bottle is a longitudinal opening from the lower part of the bottle mouth to the bottom of the bottle. In order to ensure a low damage rate of the bottle when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com