Picking equipment

A technology of equipment and area selection, applied in the direction of conveyor control devices, instruments, storage devices, etc., can solve the problems of product collection container handling, wrong product collection containers or items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

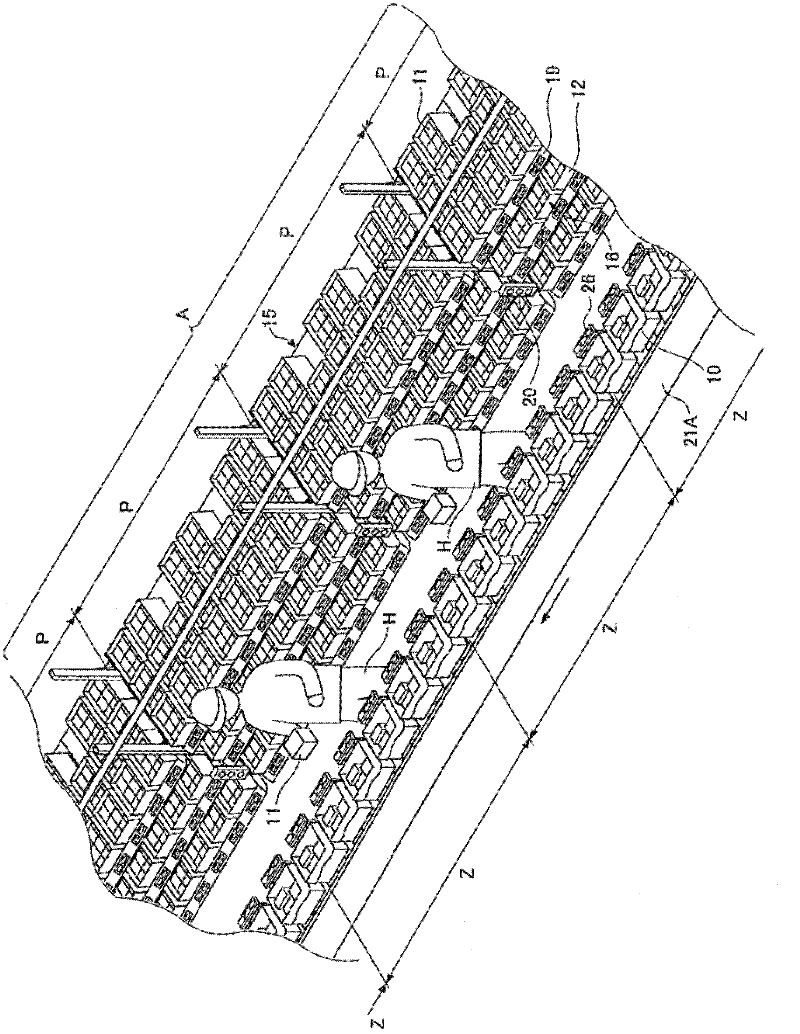

[0086] Embodiments of the present invention will be described below based on the drawings. This picking device is a picking device that collects and distributes items that are ordered (ordered) from individual pre-registered users (an example of sorting destinations) and product collection containers that are assigned to the user's order .

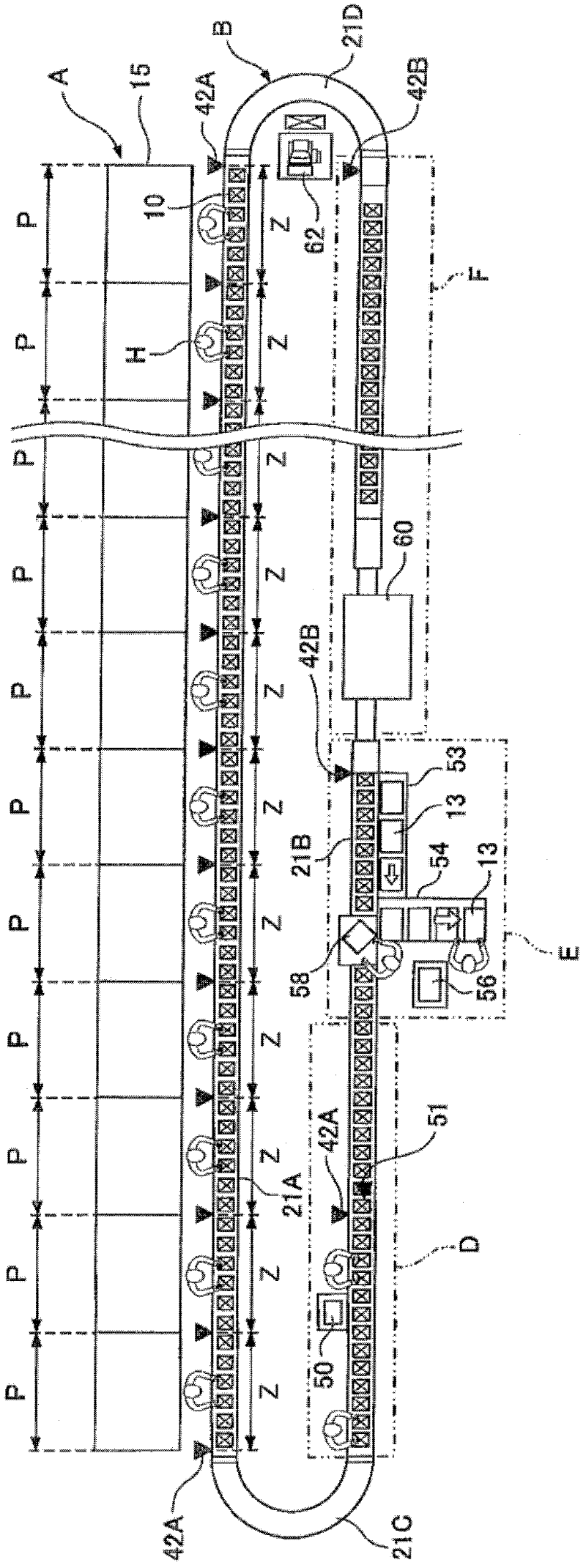

[0087] exist figure 1 In , a schematic configuration diagram of a picking device in an embodiment of the present invention is shown.

[0088] Picking equipment consists of the following components:

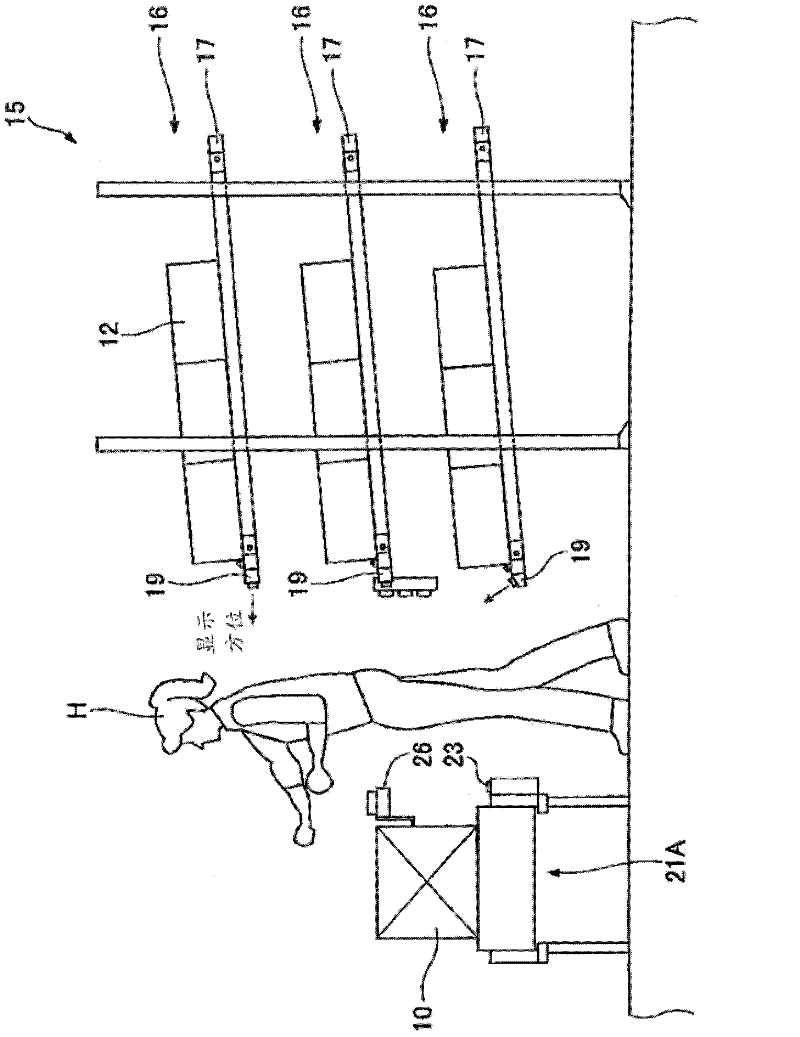

[0089] Storage line A, collected items 11 ( figure 2 ) Storage box 12 ( figure 2 ) is kept;

[0090] The conveying line B is used to recycle the product collection container 10 containing the picked items 11;

[0091] Sealing area D, in the storage line A, after the picking operation is over, seals the items 11 in the product collection container 10 transported through the transport line B;

[0092] The replacement area E is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com