Switches, especially load break switches for low voltage

A technology of switches and switch shafts, which is applied to the parts of protection switches, electric switches, protection switches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

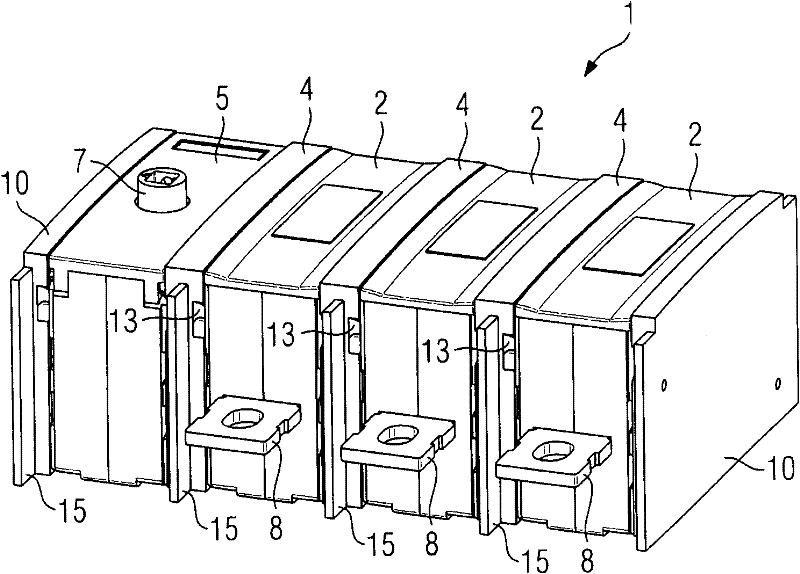

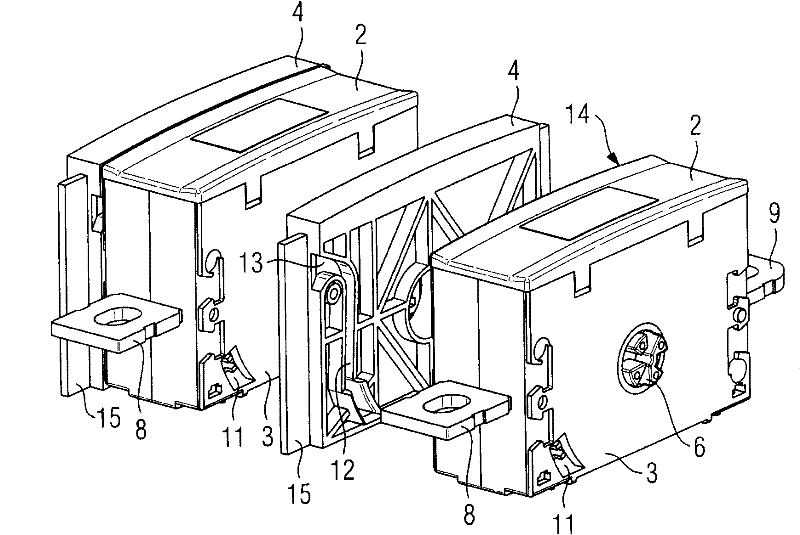

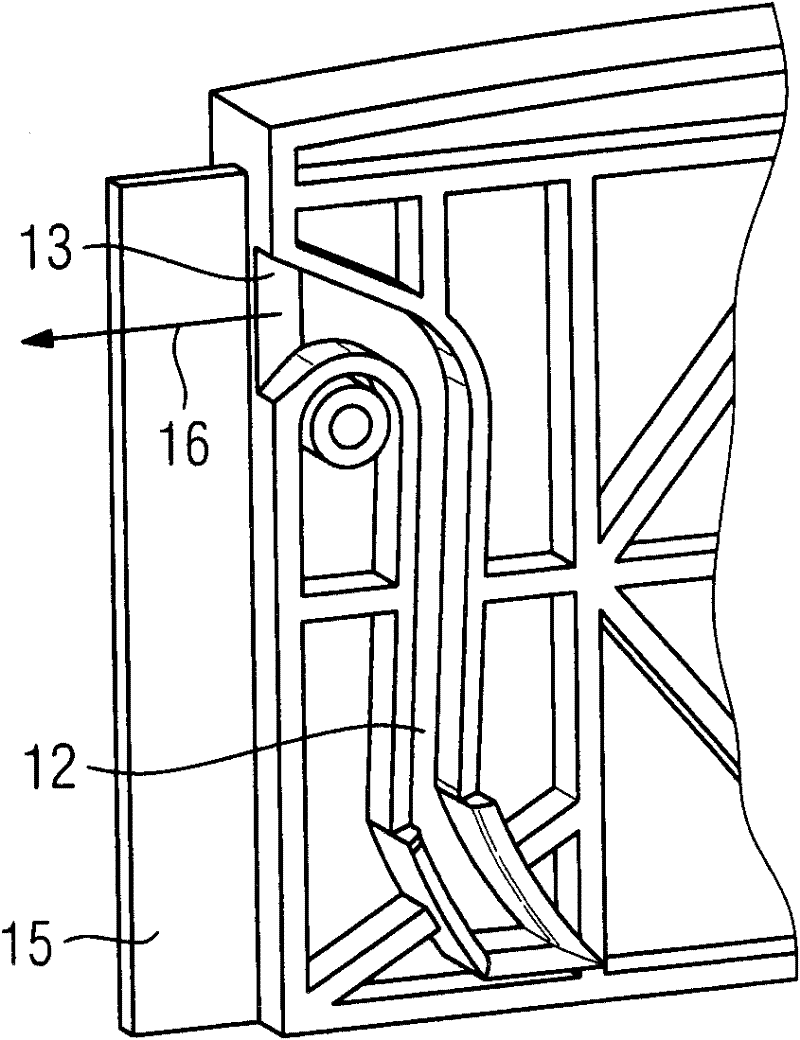

[0018] figure 1 A multipole switch 1 is shown, which has a substantially rectangular parallelepiped-shaped pole housing 2 for each phase. The side wall 3 of the electrode housing 2 (see figure 2 ) are arranged side by side side by side; the partition walls 4 are respectively located between these side walls 3 . based on figure 1 A control unit 5 is connected to the left of the three electrode housings 2, via which control unit the common switching shaft can be rotated about its longitudinal axis by means of a handle (not shown). The switching shaft consists of switching shaft section 6 (see figure 2 ) is formed and extends transversely through the side wall 3 of the electrode housing 2 . The handle is inserted into a corresponding recess of the drive shaft 7 cooperating with the switching shaft 6 for turning the switching shaft. The switching shaft can basically also be any other switching element for separating the contacts (contact pieces) for opening the switch 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com