Bottom channel inner support of foundation pit supporting structure

A technology for foundation pit support and bottom road, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as reducing the strength of basement floor, pouring together, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

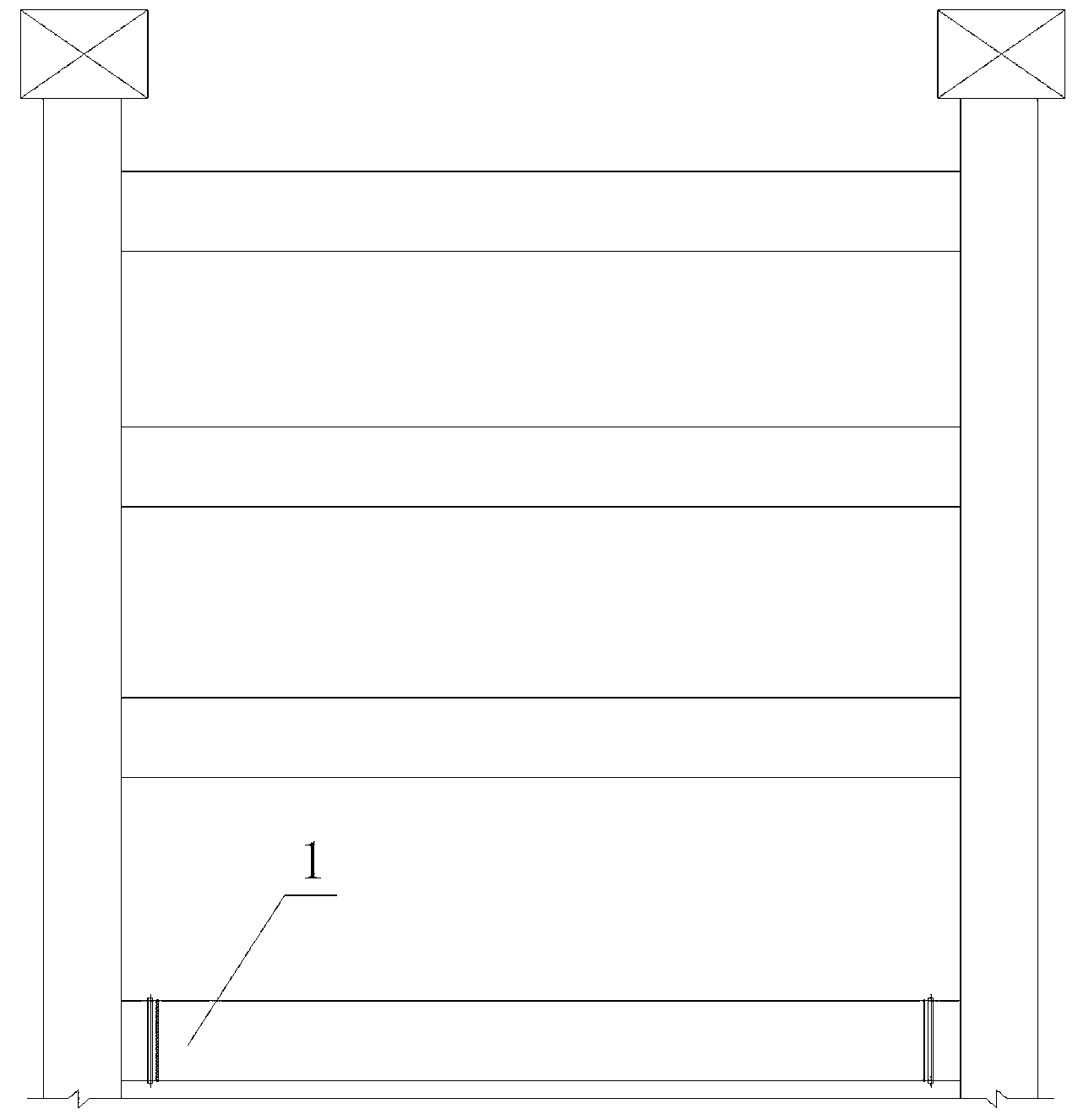

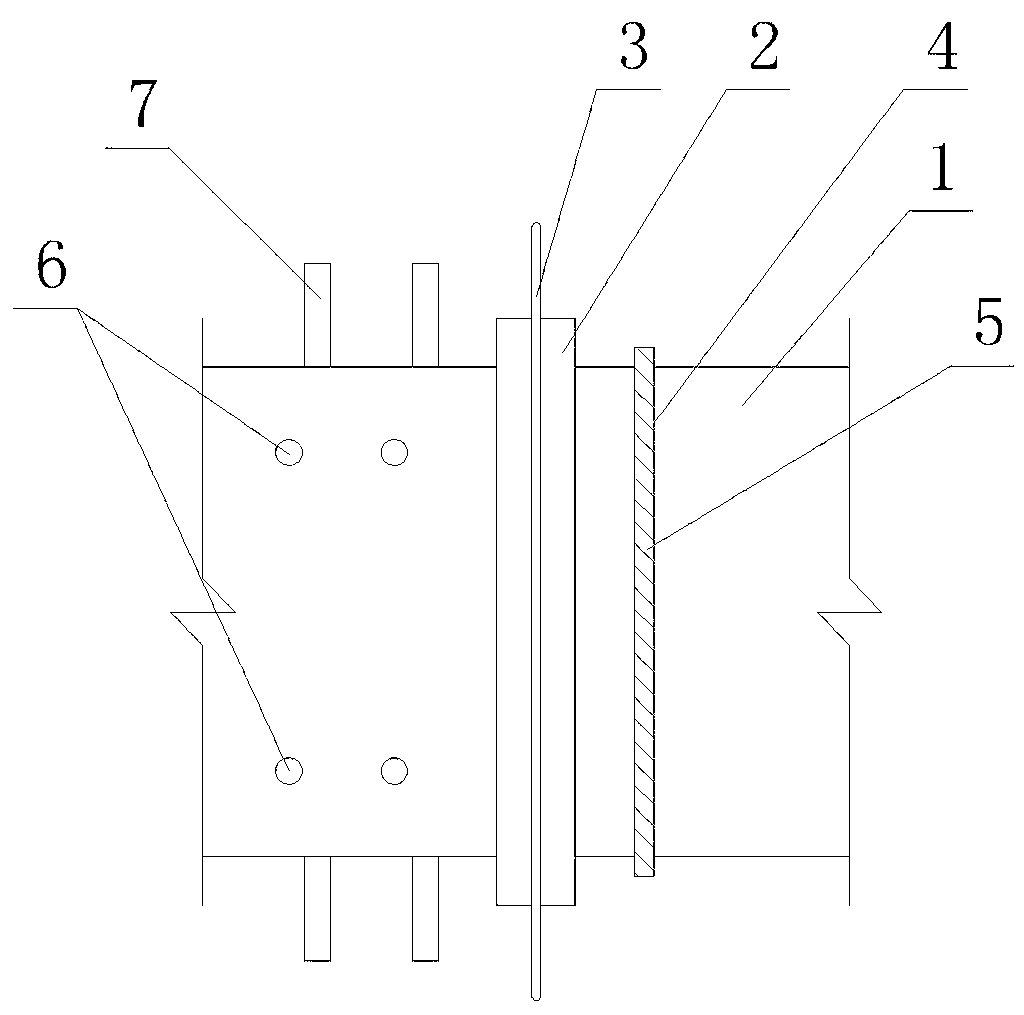

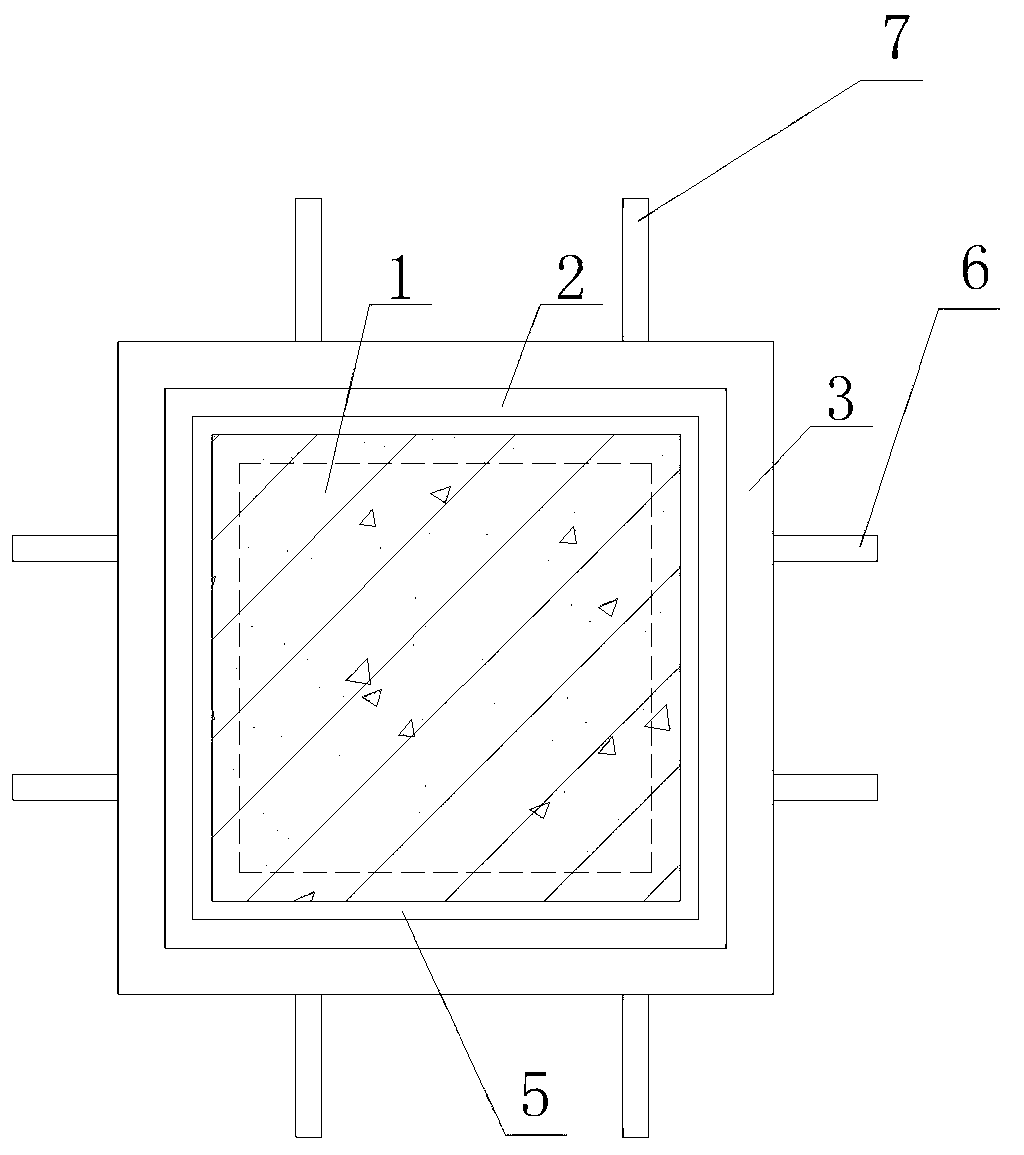

[0020] Such as figure 1 , figure 2 , image 3 As shown, the inner support of the foundation pit support structure of the present invention includes a plurality of inner supports 1 located at the same elevation (ie, horizontal height) of the bottom layer. The four sides of the node area of each inner support 1 are provided with annular concrete bosses 2 protruding from the four sides. The distance between the concrete boss 2 and the retaining pile wall of the foundation pit is 0.8m. Specifically, the distance between the outside of the concrete boss 2 (that is, the surface close to the retaining pile wall) and the retaining pile wall of the foundation pit is 0.8m . A circle of water-stop steel plates 3 is anchored on the concrete boss 2, and the circle of water-stop steel plates 3 protrudes from the four sides of the concrete boss 2; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com