Rotary joint locking device

A technology of rotating joints and locking devices, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of excessive load at the end of the manipulator, failure of the locking mechanism, and insufficient load at the rotating joints, and achieves broad application prospects. , to solve the effect of locking failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention are given below with reference to the accompanying drawings, which are used to further describe the present invention.

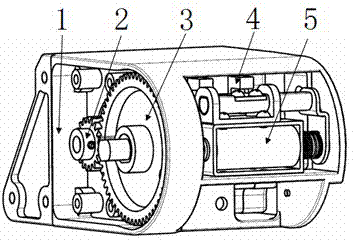

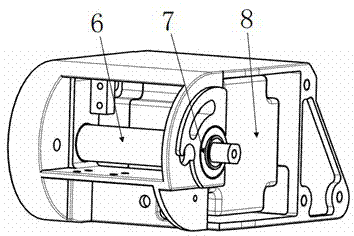

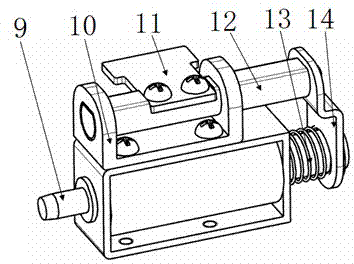

[0016] The rotary joint locking device of the present invention refers to the attached Figure 1-3 , including a rotary joint mechanism and a locking mechanism, the rotary joint mechanism includes a support 1 , a pinion 2 , a large gear 3 , a rotating shaft 6 , a copper sleeve 7 , and a motor 8 . A motor 8 is installed on the supporting member 1, and the two ends of the rotating shaft 6 are installed on the supporting member 1 through two copper sleeves 7. The coaxial large gear 3 is arranged on the rotating shaft 6, and the output shaft of the motor 8 is provided with The coaxial pinion 2, the bull gear 3 and the pinion 2 are meshed for transmission. The motor 8 drives the rotating shaft 6 to rotate through the deceleration of the bull gear 3 and the pinion 2 . A massage device is connected and fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com