Plasma venting reforming gasoline hydrogen production device and system

A technology for reforming gasoline and hydrogen production equipment, which is applied in the direction of charging system, combustion air/combustion-air treatment, adding non-fuel substances to fuel, etc., and can solve the problems of low engine NOx emission levels and restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

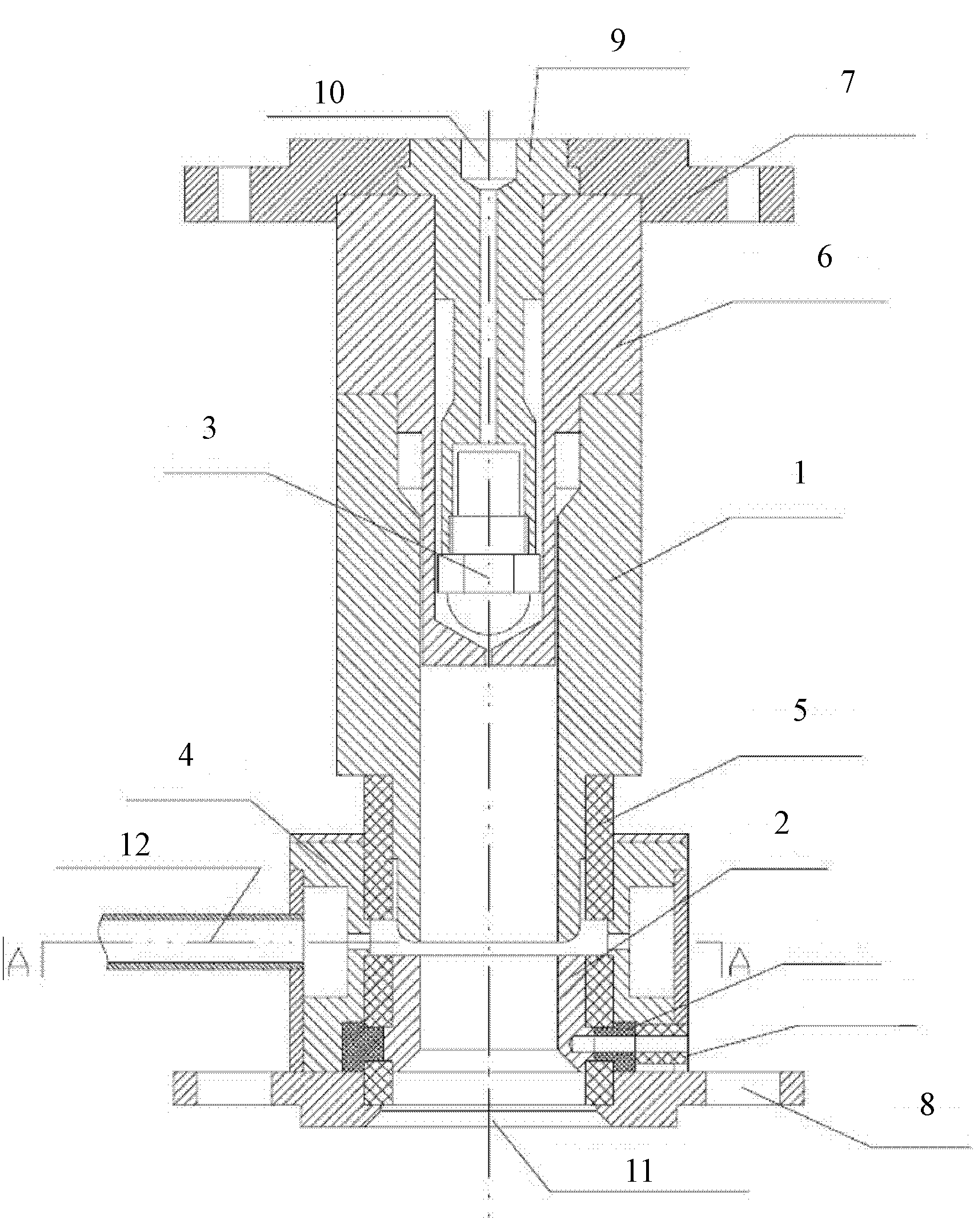

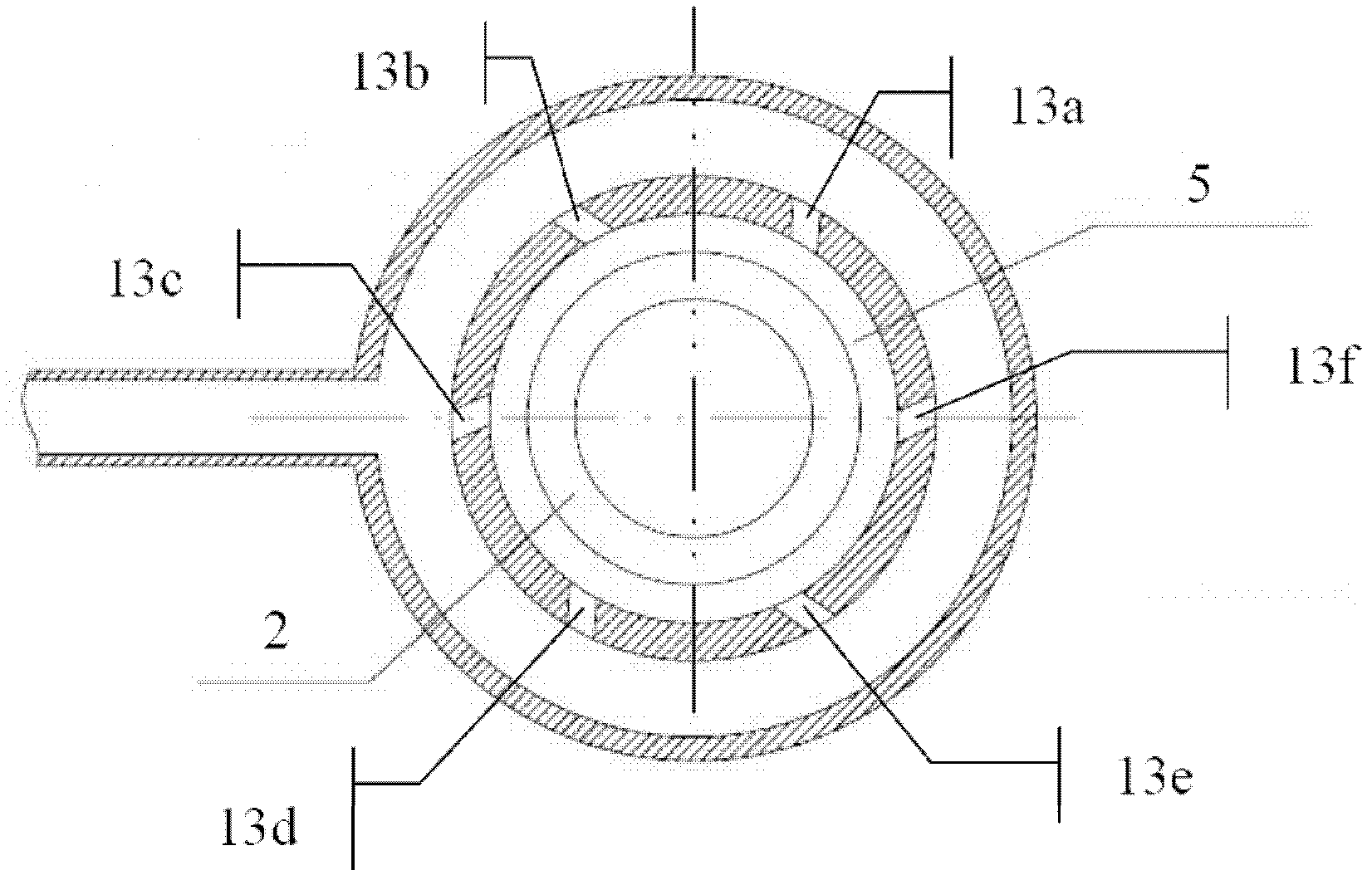

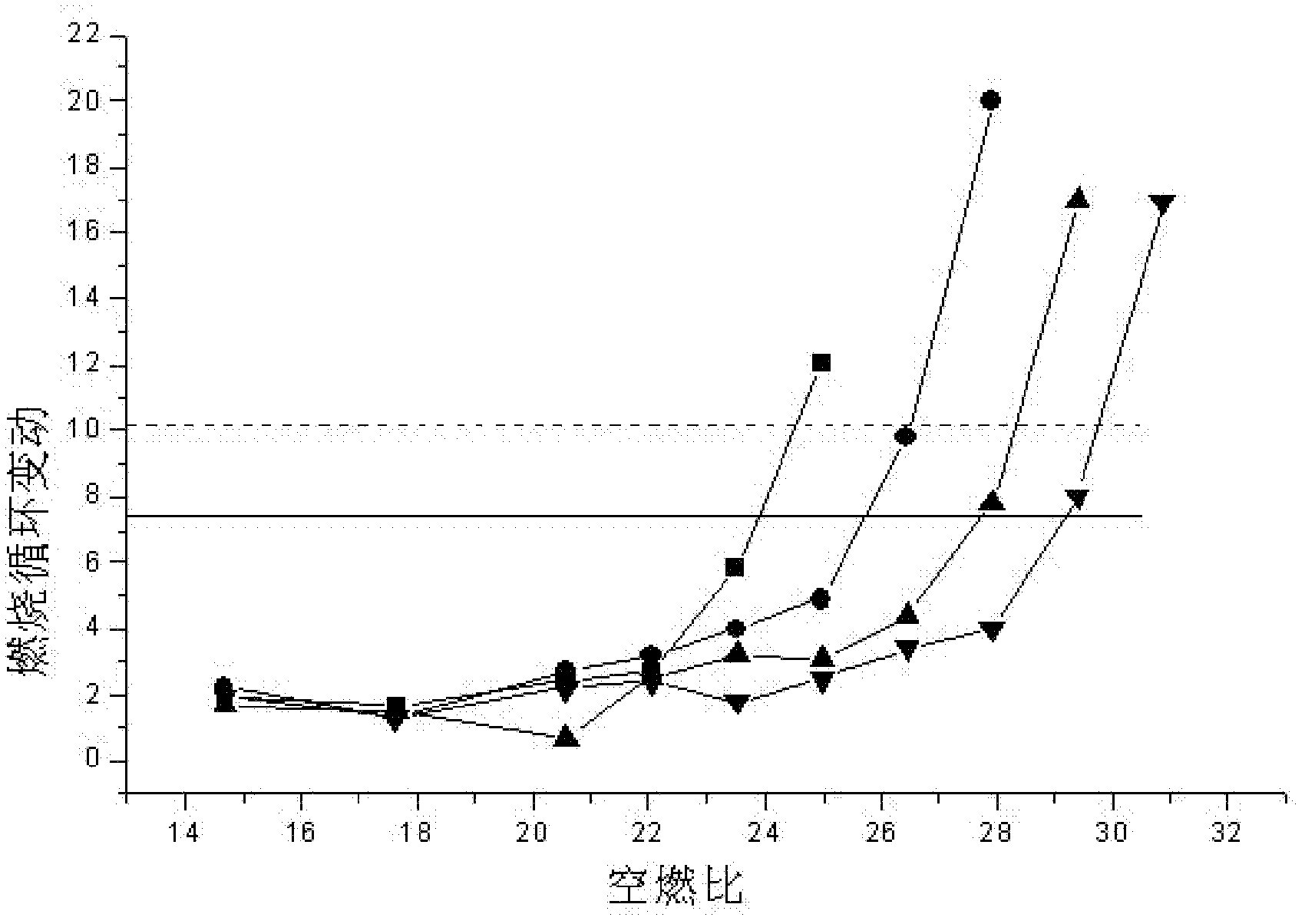

[0028] Example:

[0029] Plasma exhaust gas reforming gasoline hydrogen production device, including: a cylindrical first electrode 1, a cylindrical second electrode 2 coaxial with the first electrode, with the same inner diameter and a gap in the axial direction, located at the first electrode The gasoline injector 3 at the center of the inner shaft, the electrode covering ring 4 covering the gap between the first electrode and the second electrode, the covering ring and the electrode are insulated by a magnetic ring 5, and there is at least one on the covering ring Air hole, the air hole is connected with the exhaust port of the engine, located on the second end cover 8 on the end face of the second electrode, and the second end cover includes a reformed gas outlet 11 communicating with the inner cavity of the second electrode.

[0030] The fuel injector is located in the fuel injector seat, the fuel injector seat is nested in the oil inlet bracket seat 6, the first end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com