Coal mining method by filling on blasting mining face of thin coal seam and relevant equipment

A technology for filling coal mining and working faces, which is applied to mining equipment, filling materials, ground mining, etc., to achieve the effect of continuous filling coal mining and efficient filling coal mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

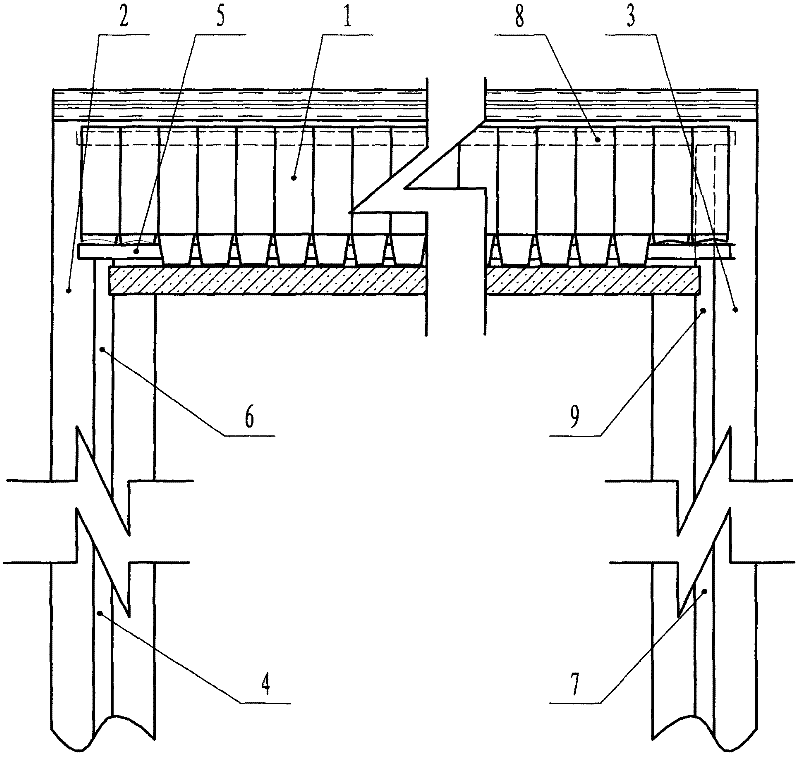

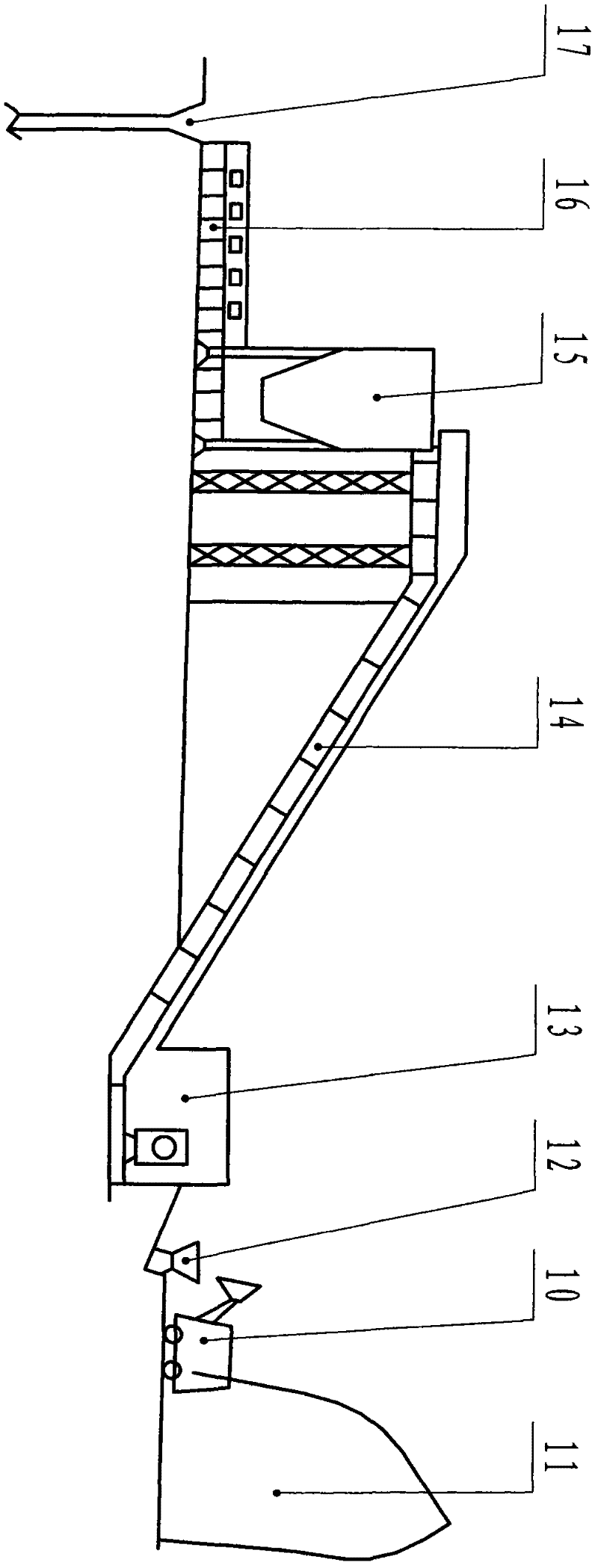

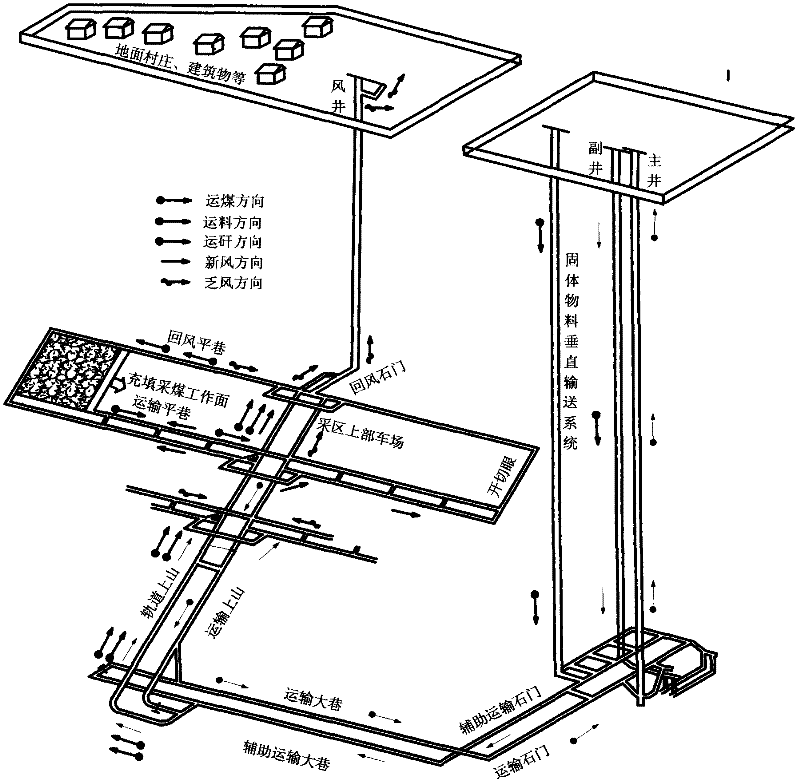

[0031] like figure 1 As shown, thin seam backfill coal mining is an organic synthesis of coal mining and mechanized solid backfill. The coal mining method of backfilling in the thin coal seam blasting mining face, compared with the traditional blasting mining face, the thin coal seam solid filling coal mining can realize the parallel operation of coal mining and filling under the cover of the same hydraulic support 1, and the thin coal seam solid filling coal mining face The arrangement is basically the same as that of the traditional blast mining face, the difference is that the filling face is arranged behind the coal face, that is, on the side of the goaf, and a solid filling material is arranged in the return air lane of the face. The conveyor, either a belt conveyor or a scraper conveyor, transports the solid filling material to the solid filling material scraper conveyor 8 . This arrangement of the working face can realize the parallel operation of filling and coal mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com