Print carriage

一种打印机、喷墨头的技术,应用在在织物打印和整理领域,达到减小横越时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

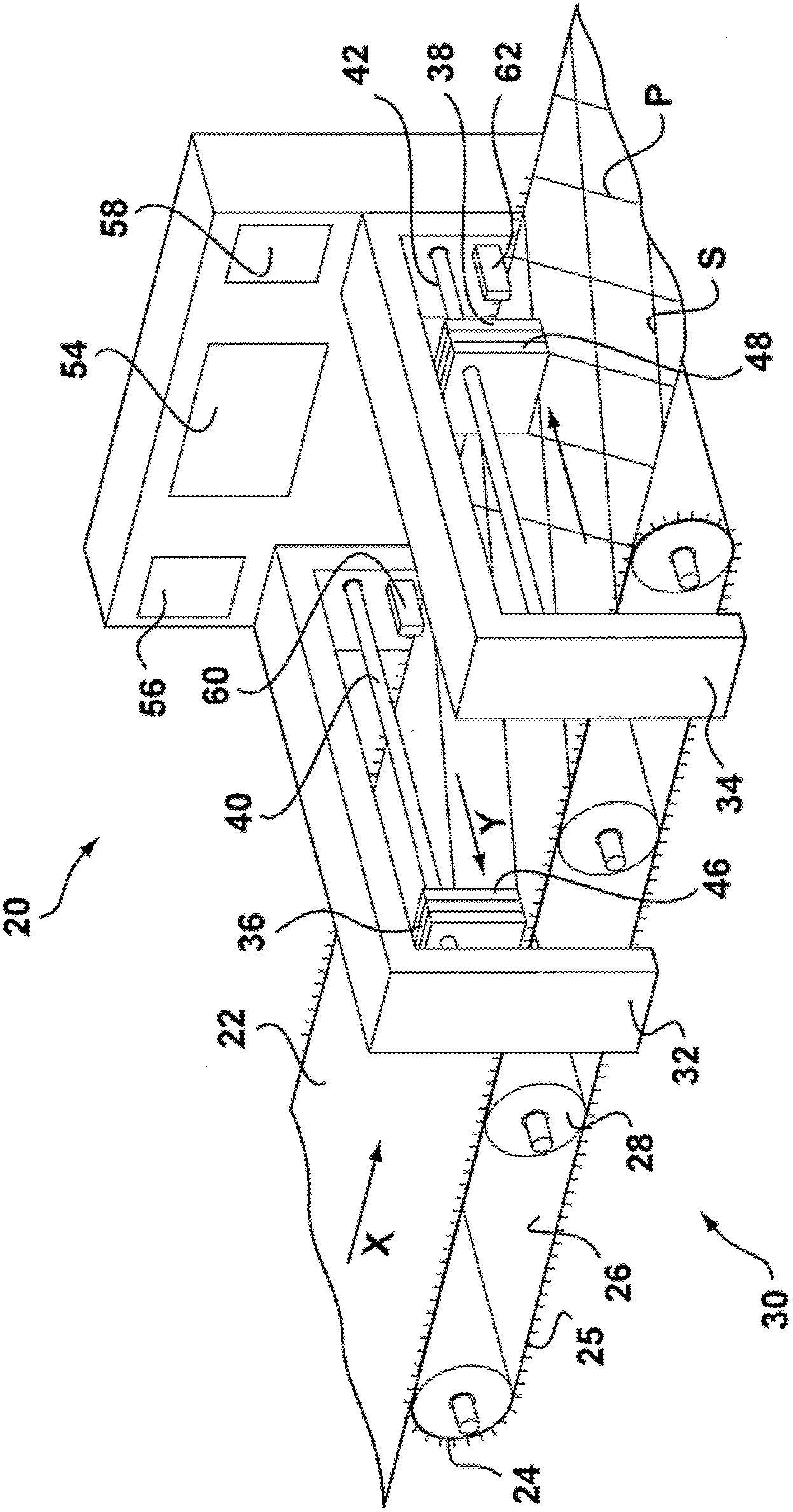

[0057] The following is a description of certain embodiments of the invention, given by way of example only, with reference to the accompanying drawings.

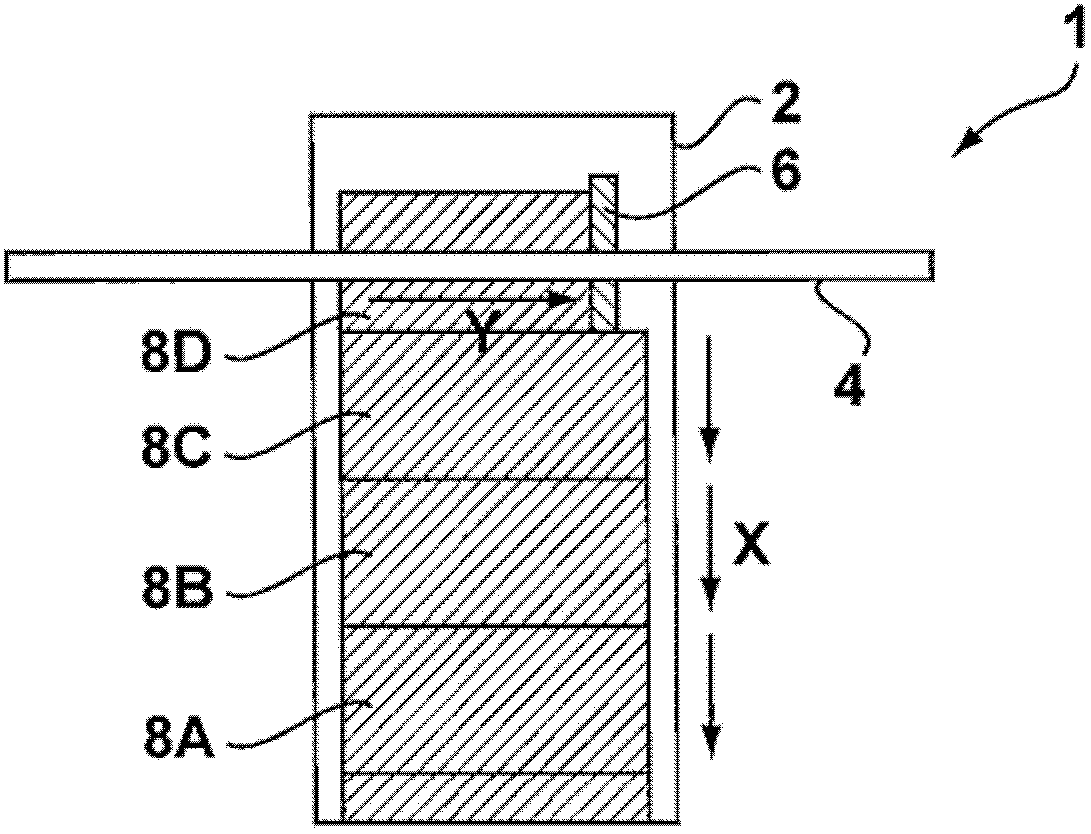

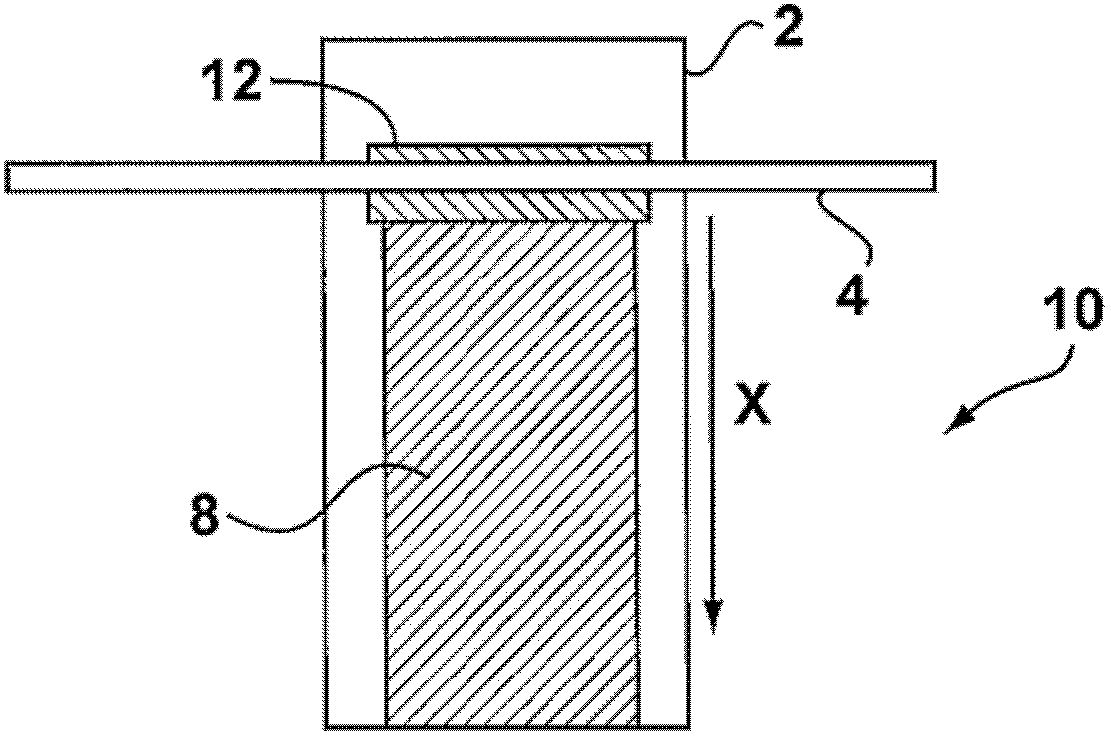

[0058] refer to figure 1 , a conventional traverse printhead system 1 is shown printing on a substrate 2 using inkjet technology. The substrate 2 is transported in direction X past a beam 4 on which is mounted a transverse inkjet print head 6 comprising a large number of nozzles. In operation, the printhead 6 traverses the substrate 2 in direction Y and prints a first pass 8A across the substrate with a width corresponding to the length of the printhead 6 . Although illustrated as a uniform layer, pass 8A is actually composed of thousands of tiny droplets or pixels. Substrate 2 is then moved forward by an increment corresponding to the width of pass 8A and paused. The printhead 6 then traverses back across the substrate 2 to generate the second pass 8B. Further passes 8C, 8D are carried out in the same way. In practice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com