Atomized liquid oral cleaning appliance

An oral cleaning and liquid technology, which is applied in the direction of cleaning the tooth cavity, etc., can solve the problems of regular replacement and expensive gas tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

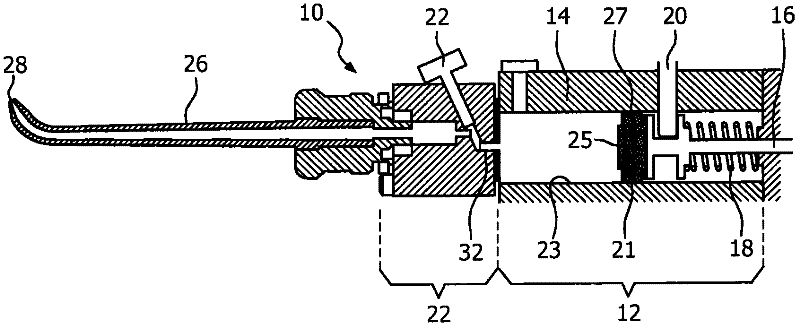

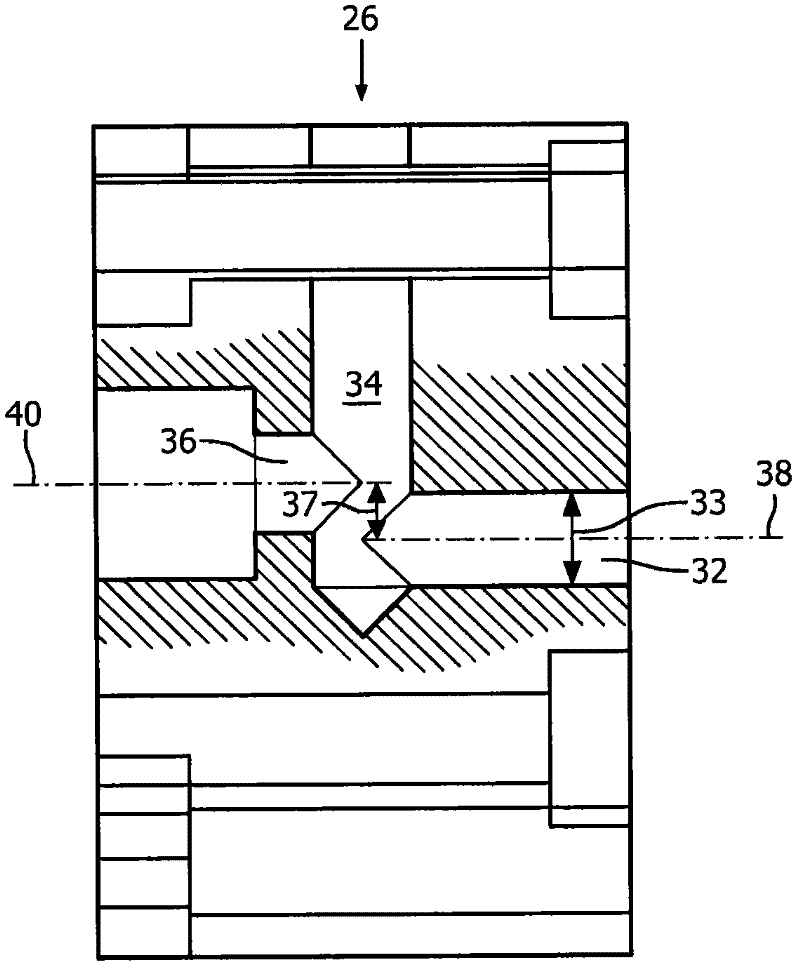

[0008] figure 1 An oral cleaning device using liquid droplets for cleaning produced by a low pressure gas system is shown. The device 10 includes a spring assembly 12 . The spring assembly 12 includes a hollow body 14 having a piston 16 and a spring 18 mounted therein for reciprocating movement. Piston 16 is moved to the rear of body 14 by user operation of an actuating element or button 20 engaged to the piston against the action of spring 18 . The front end 21 of the piston comprises a head element having an airtight connection with the inner wall 23 of the main body 14 . The front end has a raised central portion 25 with a surrounding grooved portion 27 . Upon releasing the actuating member and effecting the forward movement of the piston (pushed by the action of the spring 18), the head member pushes the air present in the body 14 into the mixing chamber 22, as will be described in more detail below and described in figure 2 shown in . With each application of air mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com