Comb segment for a circular comb

A needle plate seat and cylinder technology, which is applied in combing machines, textiles, papermaking, fiber processing, etc., can solve the problems of insufficient or even impossible cleaning, reduced carding effect, poor accessibility, etc., and achieve rapid and Economical manufacture and assembly, good carding effect, mechanically robust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

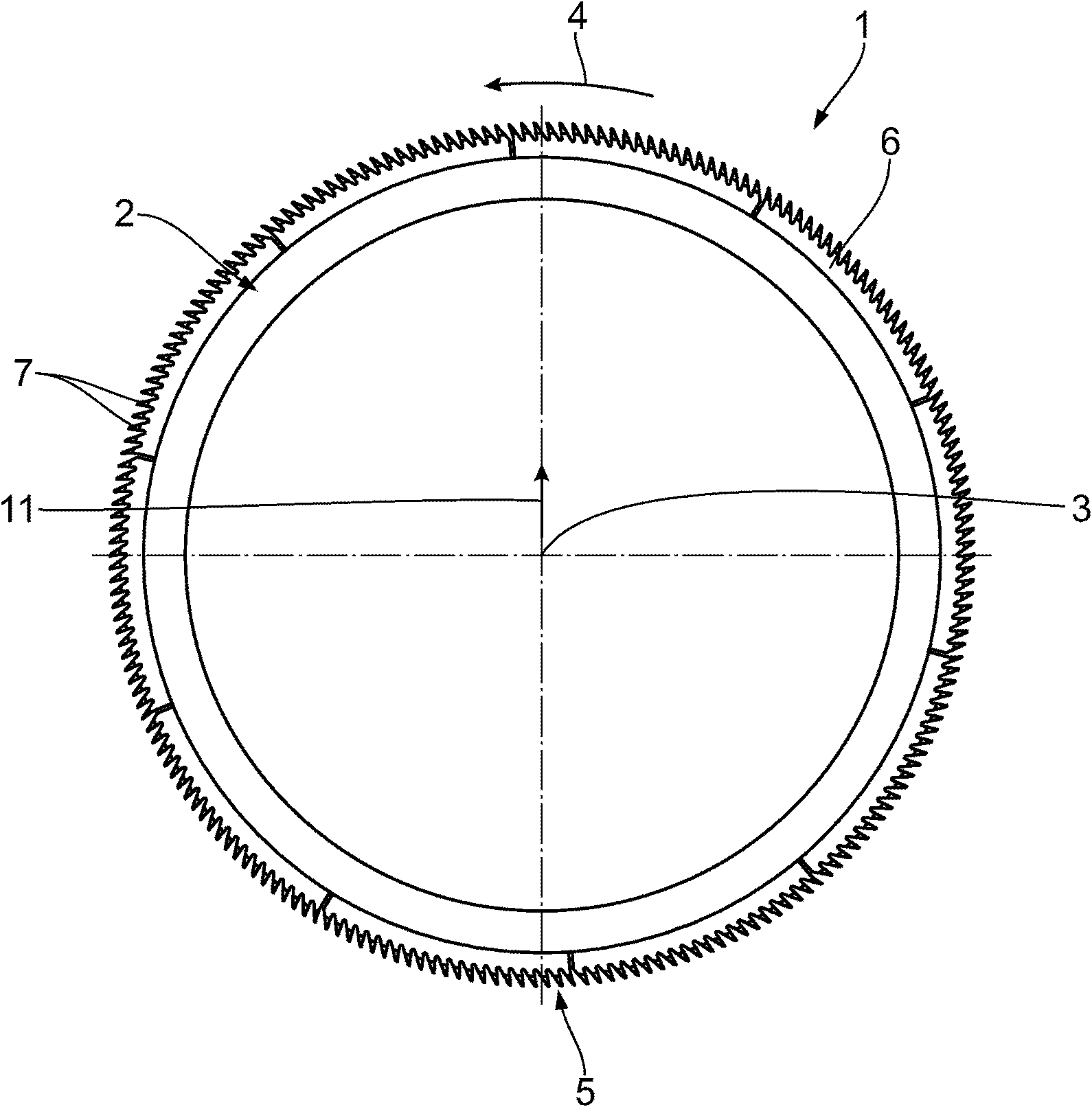

[0022] figure 1 The circular comb 1 shown in has a hollow cylindrical combing cylinder 2 with an axis of rotation 3 . A total of 10 cylinder needle holders 5 are mounted on the combing cylinder 2 along the direction of rotation 4 . The axial length of the cylinder needle plate seat 5 parallel to the axis of rotation 3 defines the combing area of the circular comb 1 . Each cylinder needle plate seat 5 includes a plurality of identical punched combs 6 which are basically arranged sequentially along the direction of the rotation axis 3 , wherein each comb 6 has a plurality of teeth 7 . In the illustrated embodiment, the comb blade 6 is preassembled as a so-called tie rod and fixed on the combing cylinder 2 by clamps. Or, tie bar also can be connected with combing cylinder 2 by screw. Comb sheet 6 also can not be preloaded, but is directly contained on the combing cylinder 2 with group structure and is bonded with it.

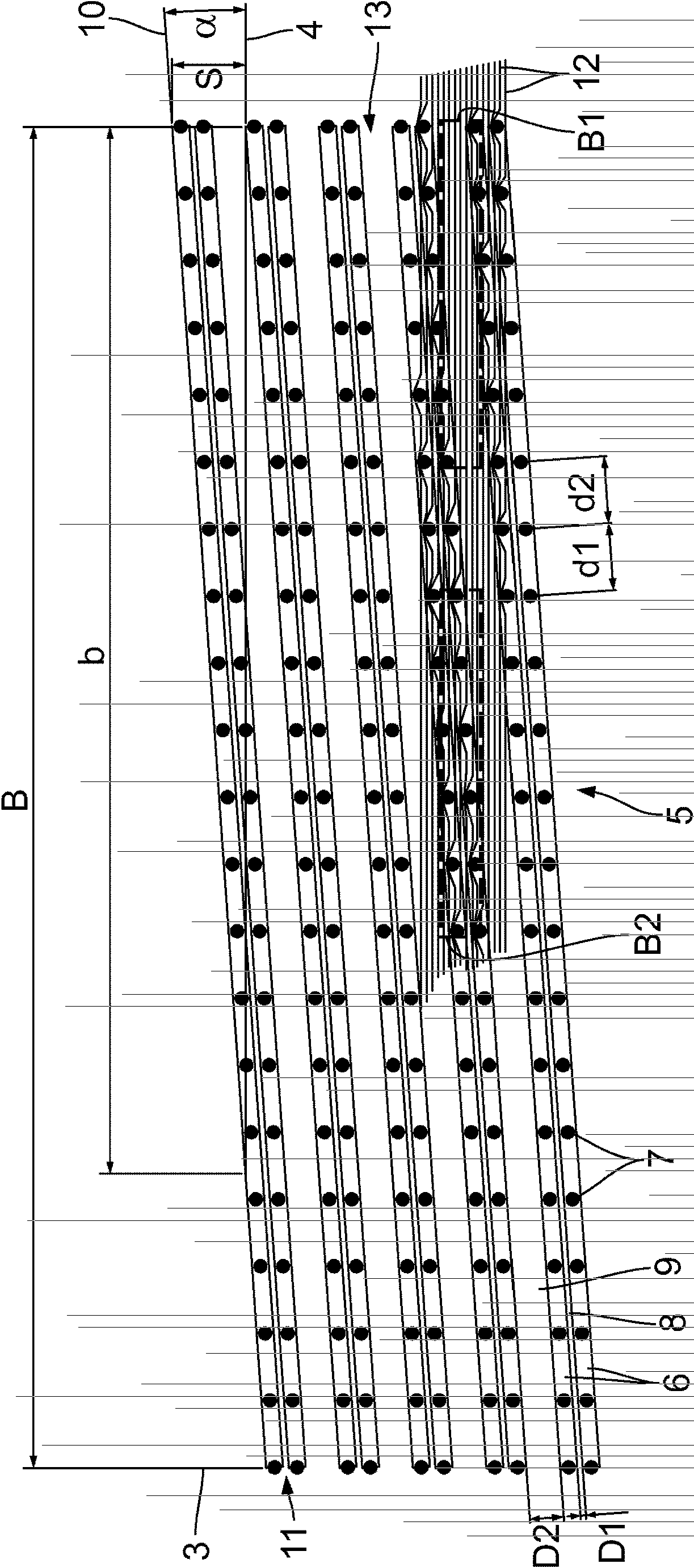

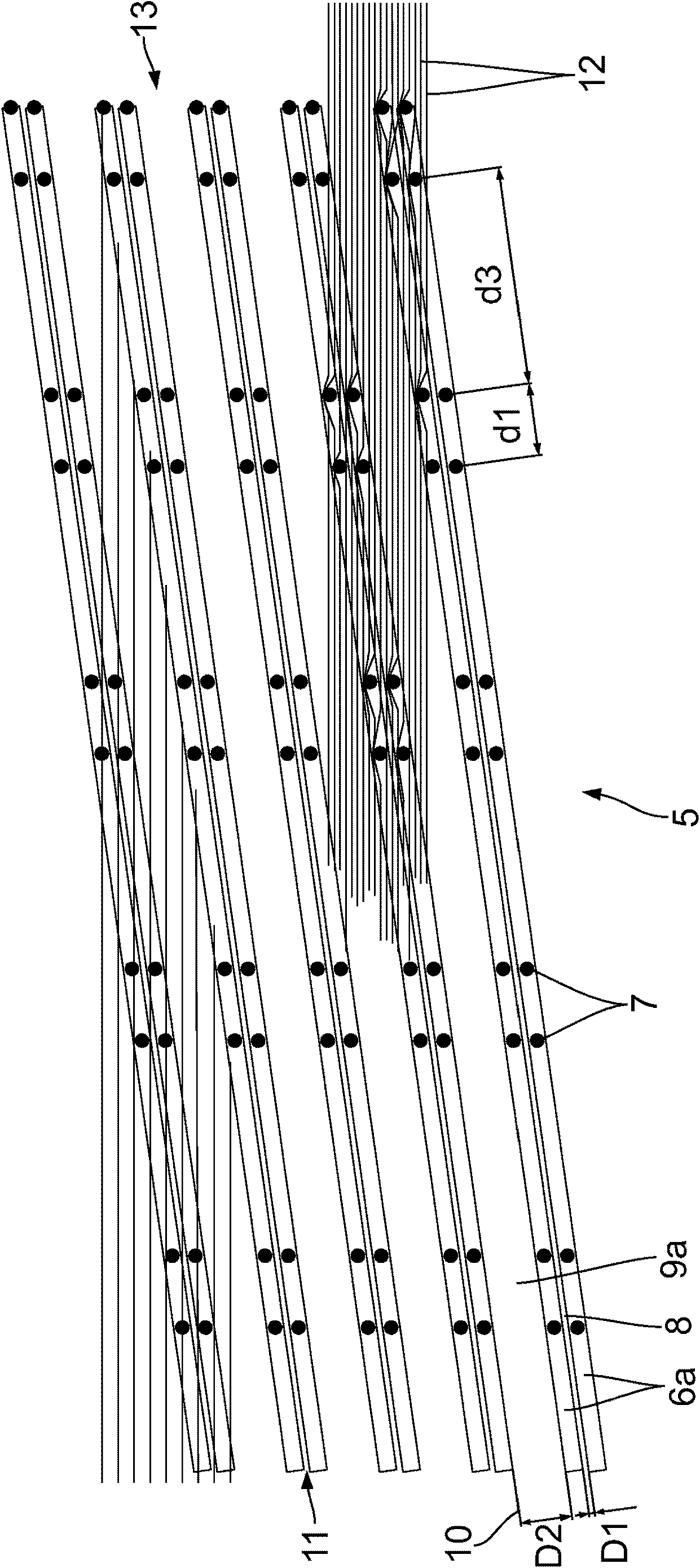

[0023] figure 2 The cylinder needle bar seat 5 is sch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com