Pharmaceutical compositions for treating bacterial infections

A composition and drug technology, applied in the directions of antibacterial drugs, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve the problems of affecting the pulverization efficiency, difficult to remove the bonded drugs, and the pulverization work has to be terminated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

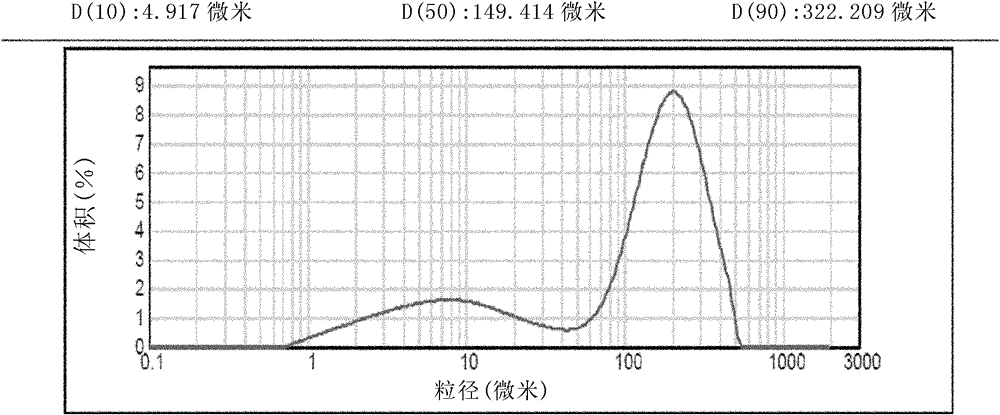

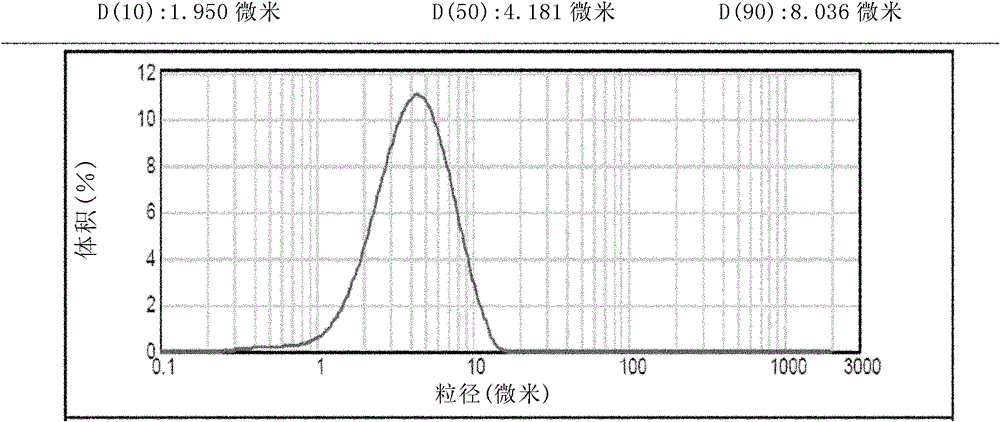

[0167] Embodiment 1: co-micronizing and pulverizing with sodium lauryl sulfate and MRX-I (small batch)

[0168] Mix 38.9g MRX-I bulk drug (D(50)=78 micron, D(90)=307 micron) with 1.9g sodium lauryl sulfate (the ratio of drug to excipient is about 100:5) and pass through 30 mesh Sieve 3 times, carry out micronization with airflow mill (JGM-H100 type airflow mill of Huali Company), pulverization pressure is about 8bar, feed rate is about 15g / min, micronization treatment once. After micronization and pulverization, 40.0 g of the micronized drug was obtained with a yield of 98.0%.

[0169] The particle size distribution of the micronized material was measured with a Malvern particle size analyzer, and the results showed that D(50) was 2.3 μm and D(90) was 5.0 μm.

[0170] Co-micronizing the drug and sodium lauryl sulfate, the drug yield is high, the micronization effect is good, and no clogging phenomenon is seen.

Embodiment 2

[0171] Embodiment 2: use sodium lauryl sulfate and MRX-I co-micronized pulverization (bigger batch)

[0172] Mix 422.4g MRX-I bulk drug (D(50)=20 microns, D(90)=185 microns) with 21.1g sodium lauryl sulfate (the ratio of drug to auxiliary material is about 100:5), and pass 16 Mesh sieve 3 times, then carry out micronization with airflow mill (JGM-H200 type airflow mill of Huali Company), pulverization pressure 8 ± 0.5bar, feed rate about 75 ± 25g / min, micronization treatment 2 times. After the crushing was completed, a total of 436.5 g of micronized materials were recovered, with very little loss and a recovery rate of 98.4%.

[0173] The particle size distribution of the micronized material was measured with a Malvern particle size analyzer, and D(50) was 2.9 μm, and D(90) was 6.2 μm.

[0174]After continuous micronization of two larger batches of mixed materials, no sticking or clogging was observed in the jet mill cavity. There is little loss of medicine. The particle si...

Embodiment 3

[0175] Example 3: Co-micronizing and pulverizing with silica and MRX-I

[0176] Mix 40.1g compound MRX-I (D(50)=78 micron, D(90)=307 micron) with 0.3g silicon dioxide (the ratio of drug to excipient is about 100:0.75), and pass through a 30-mesh sieve 3 For the second time, micronize with a jet mill (JGM-H100 type jet mill of Huali Company), the pulverizing pressure is about 8bar, the feed rate is about 15g / min, and the micronization process is performed once. After micronization and pulverization, 38.5 g of micronized drug was obtained, with a yield of 95.3%.

[0177] The particle size distribution of the micronized material was measured with a Malvern particle size analyzer, and the results showed that D(50) was 3.8 μm and D(90) was 8.3 μm. After micronization, there is no sticking phenomenon in the jet mill cavity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com