System and method for operating a thrust reverser for a turbofan propulsion system

A technology of thrust reverser and turbofan, applied in jet propulsion, high-efficiency propulsion technology, machine/engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

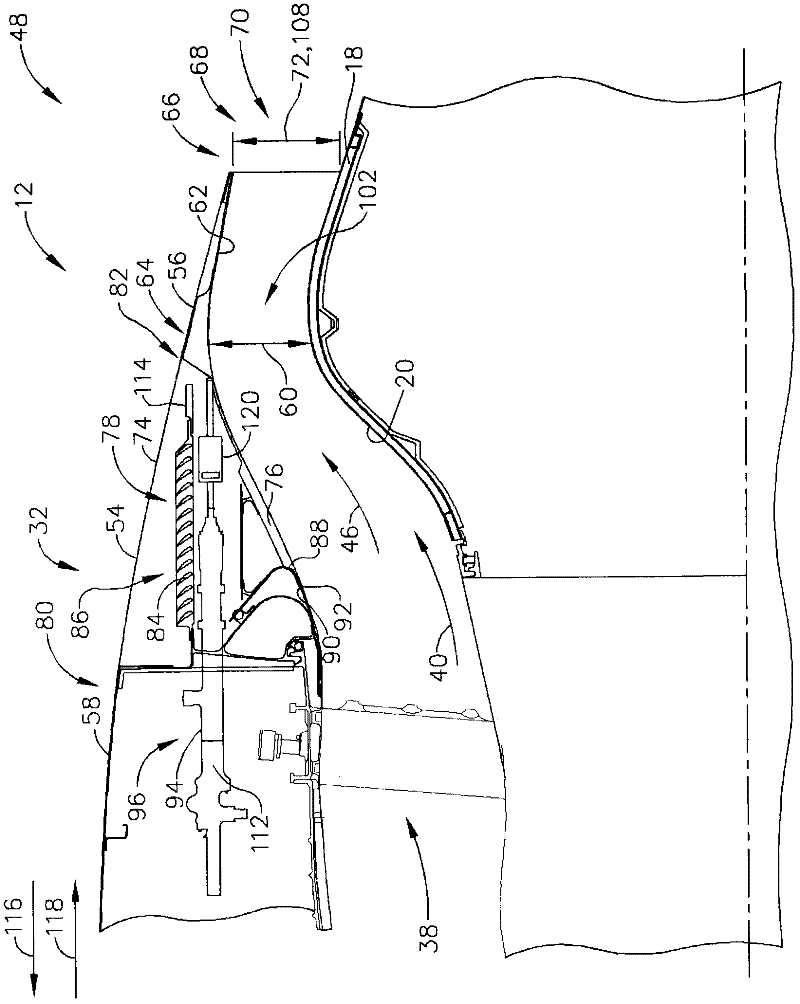

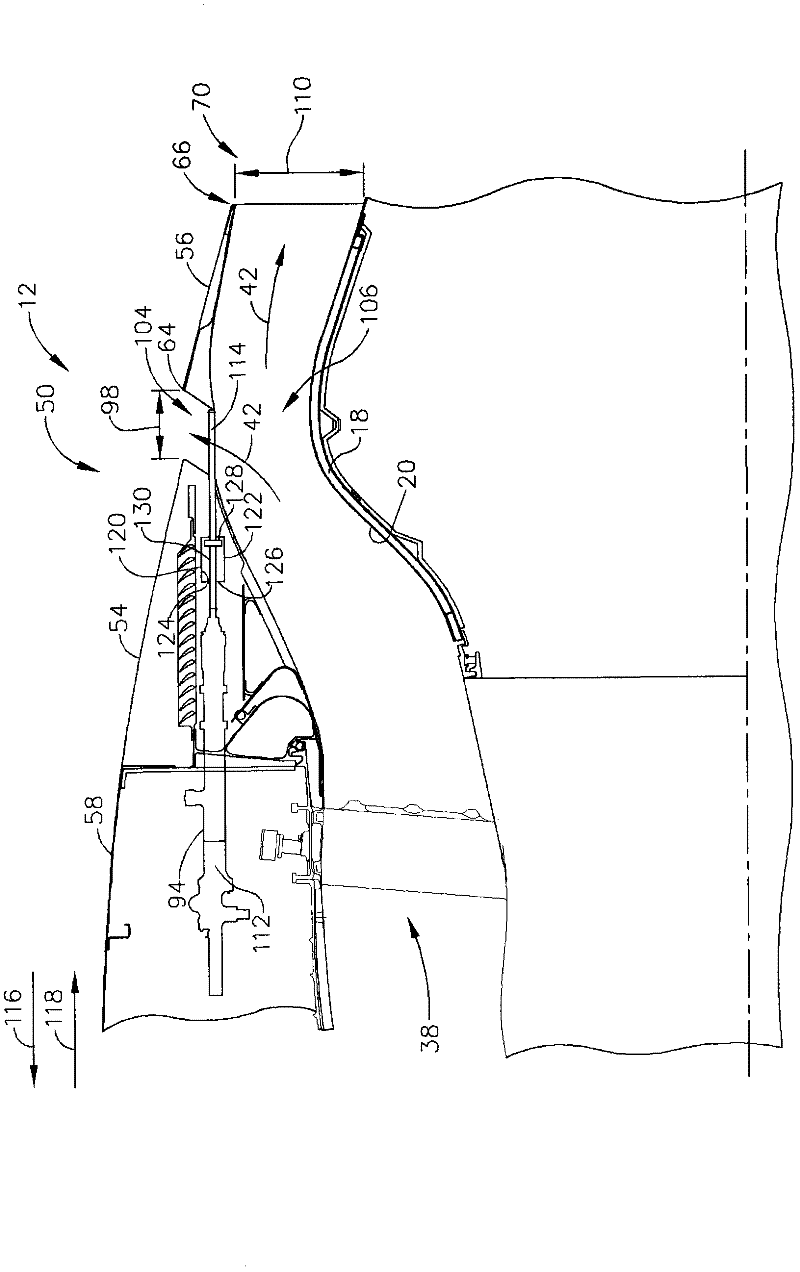

[0022] The exemplary methods and systems described herein overcome at least some of the disadvantages of known turbofan propulsion systems by providing a thrust reverser assembly that facilitates regulating airflow discharged from a turbofan engine assembly. Additionally, the thrust reverser assembly includes a first translating cowl and a second translating cowl each positionable relative to the fixed cowl to adjust a discharge zone defined between the second translating cowl and the turbofan engine assembly. Additionally, the thrust reverser assembly includes an actuator operatively coupled to the second transcowl, and a positioning assembly configured to engage the actuator to selectively move the first transcowl. By selectively positioning the first transcowl and the second transcowl, the thrust reverser assembly helps regulate airflow exhausted through the turbofan propulsion system to improve the operating efficiency of the turbofan propulsion system.

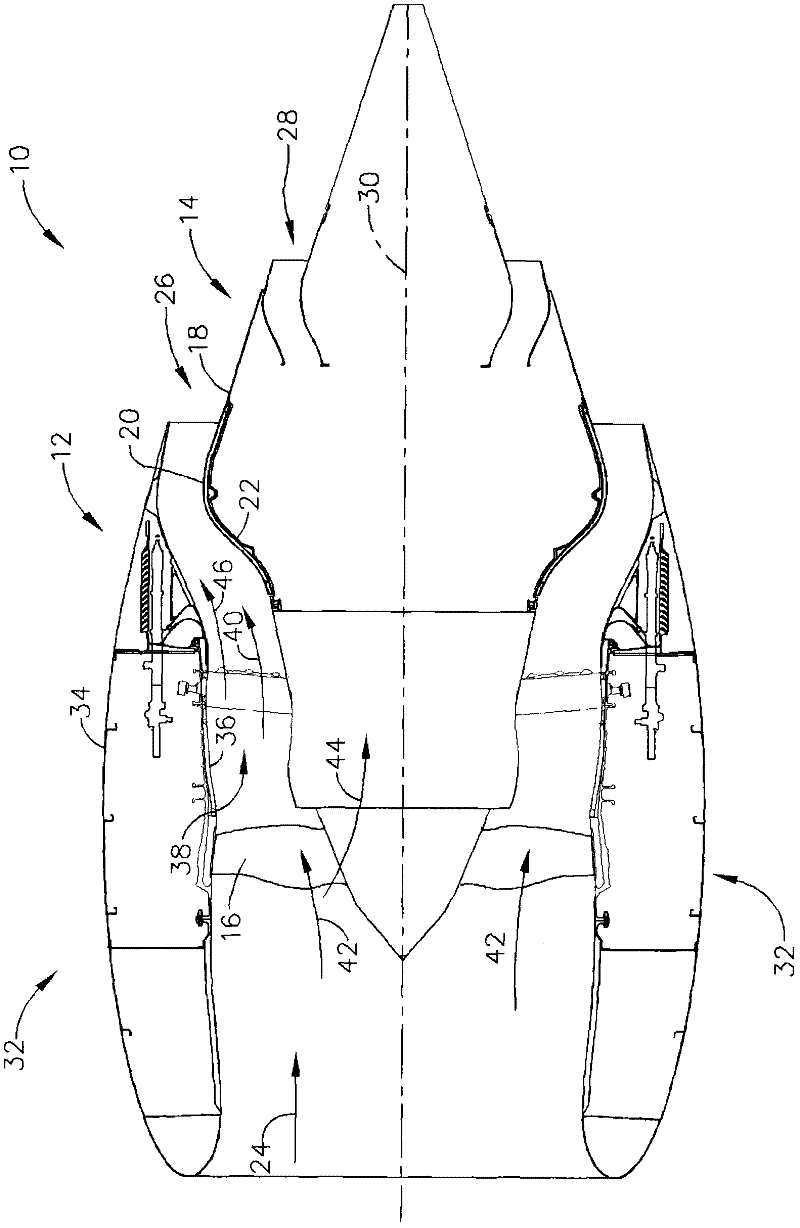

[0023] figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com