Method for positioning and calibrating magnetic strip in bankbook printer

A passbook printer and calibration method technology, applied to printing devices, printing, etc., can solve problems such as low accuracy, difficulty in accurate measurement, and influence of reading magnetic rate, and achieve high calibration accuracy, high precision, and elimination of passbook positioning differences Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

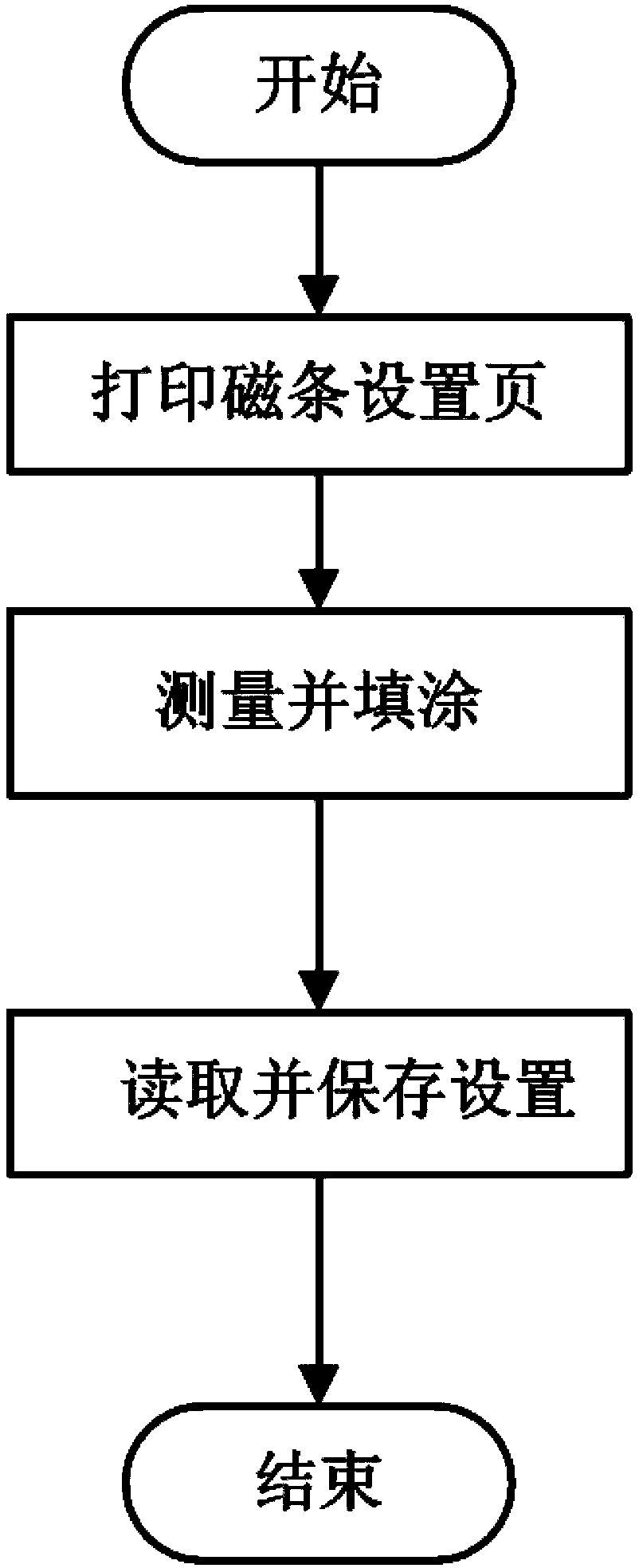

Method used

Image

Examples

Embodiment 1

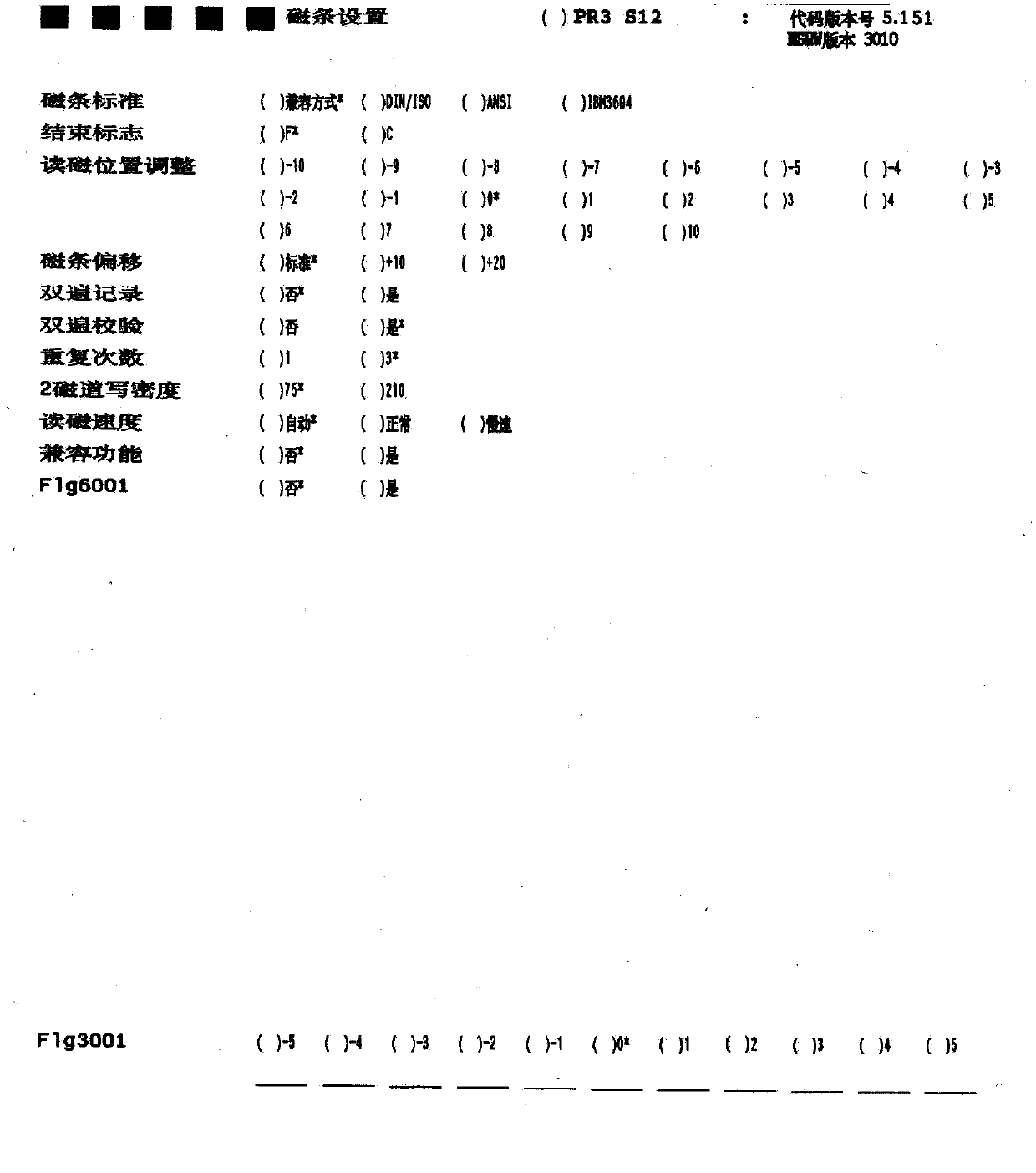

[0051] 1. Select the appropriate theoretical deviation value:

[0052] On the basis of the standard positions of the passbook theory, select 5 (total 10) positions for adjustment in the forward and backward directions. In addition to the standard position, there are 11 positions for adjustment:

[0053] -5-4-3-2-1 0 1 2 3 4 5

[0054] Among them, 0 means the theoretical standard position, in the middle; numbers with negative signs mean back folds; unsigned numbers mean forward folds.

[0055] The unit of one step of the paper-feeding mechanism is 1 / 180 inch, and the unit of passbook position adjustment is two steps of the paper-feeding mechanism, namely 1 / 90 inch. That is, the above 11 positions indicate that the distance adjusted relative to the standard position is:

[0056]-5*1 / 90 inch-4*1 / 90 inch-3*1 / 90 inch-2*1 / 90 inch-1*1 / 90 inch 0*1 / 90 inch 1*1 / 90 inch 2*1 / 90 inch 3*1 / 90 inch 4*1 / 90 inch 5*1 / 90 inch

[0057] 2. Enter the S12 magnetic strip setting menu function, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com