Non-conductor contact power transmission notebook computer using redundant magnetic core protection

A technology of contacting electrical energy and non-conductors, applied in electrical components, circuit devices, electromagnetic wave systems, etc., can solve problems affecting the safety of electricity consumption and safe production, heat generation, fire hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

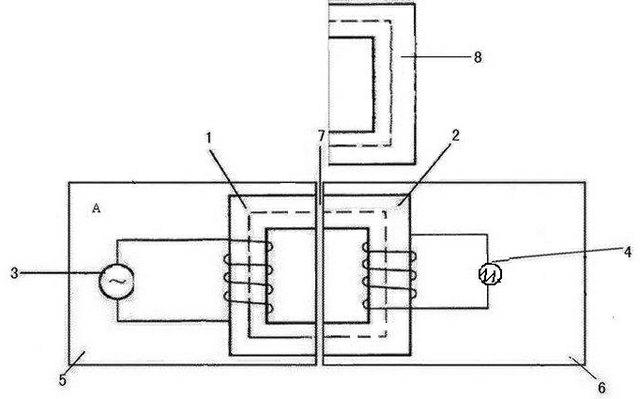

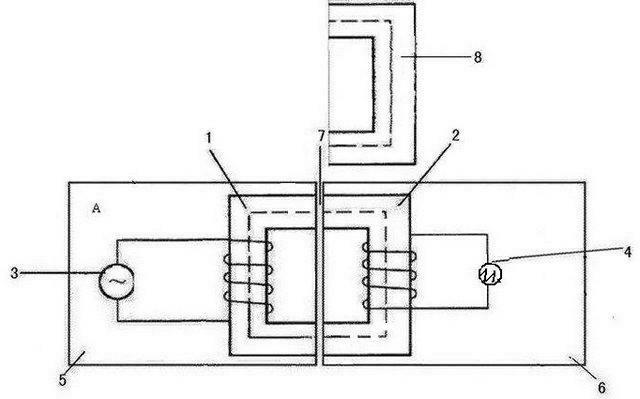

[0007] like figure 1 As shown, the notebook with non-conductor contact power transmission protected by redundant magnetic cores includes a power supply terminal A and a power consumption terminal B. The power supply terminal A includes an "E"-shaped power supply terminal core 1 and is wound on the power supply terminal iron core 1 The primary coil, the primary coil is connected to the AC power supply 3, and the power consumption terminal B includes the reverse "E"-shaped power consumption terminal iron core 2 and the secondary coil wound on the power consumption terminal iron core 2 and connected to the two secondary coils. The load at the end—notebook 4, after the power supply end A is connected to the power consumption end B, the iron core 1 of the power supply end and the iron core 2 of the power consumption end form an approximately complete "day"-shaped iron core, and the iron core 1 of the power supply end and the power consumption end The iron core 2 constitutes a close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com