An electrically heated smoking system with internal or external heater

An electric heating and heater technology, which is applied to tobacco, inhalers, and tobacco processing, can solve problems such as performance degradation and condensation of tobacco smoke, and achieve the goal of minimizing risks, heat loss, and cleaning operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

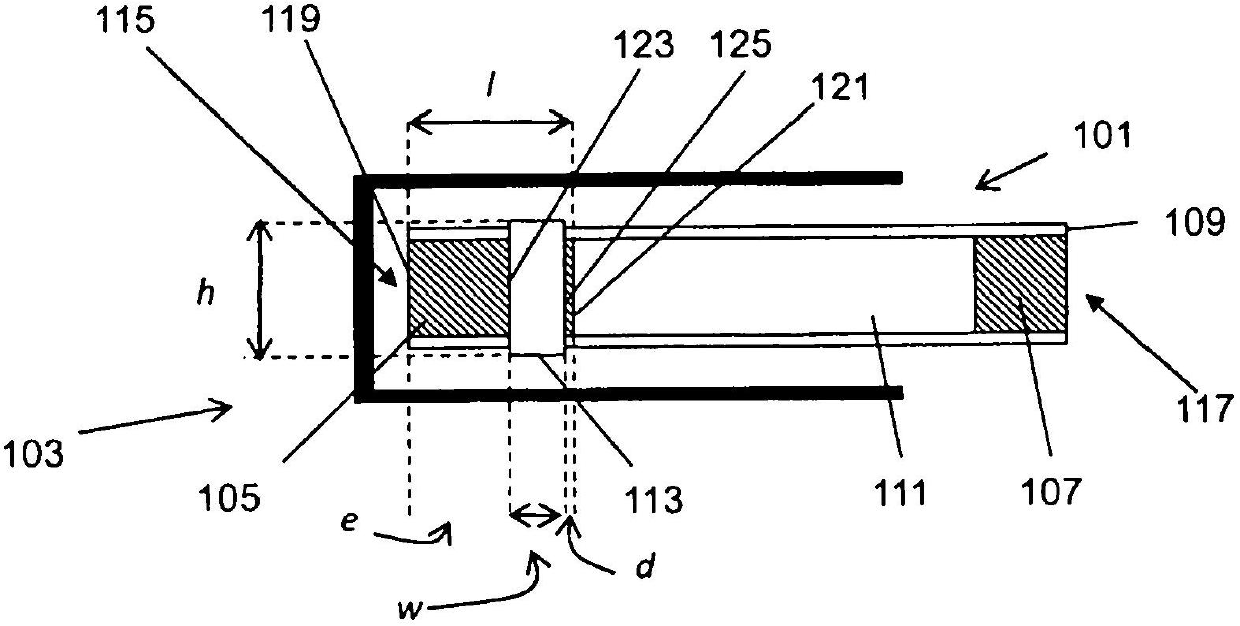

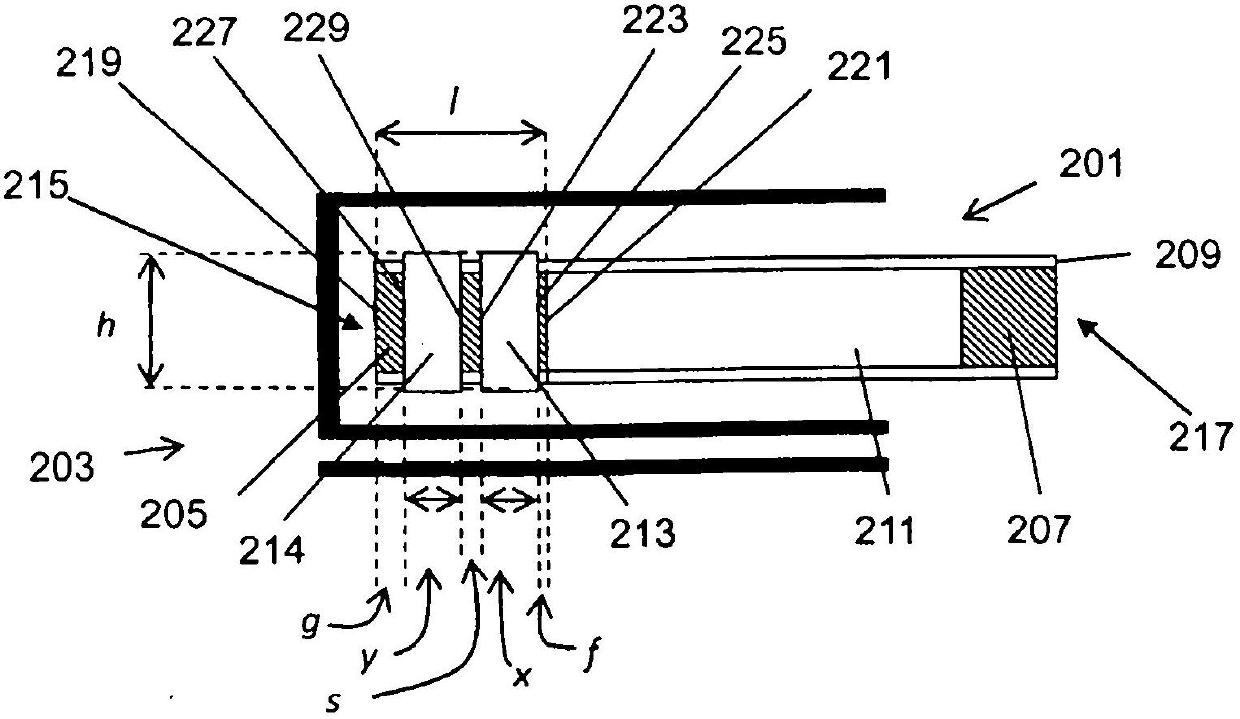

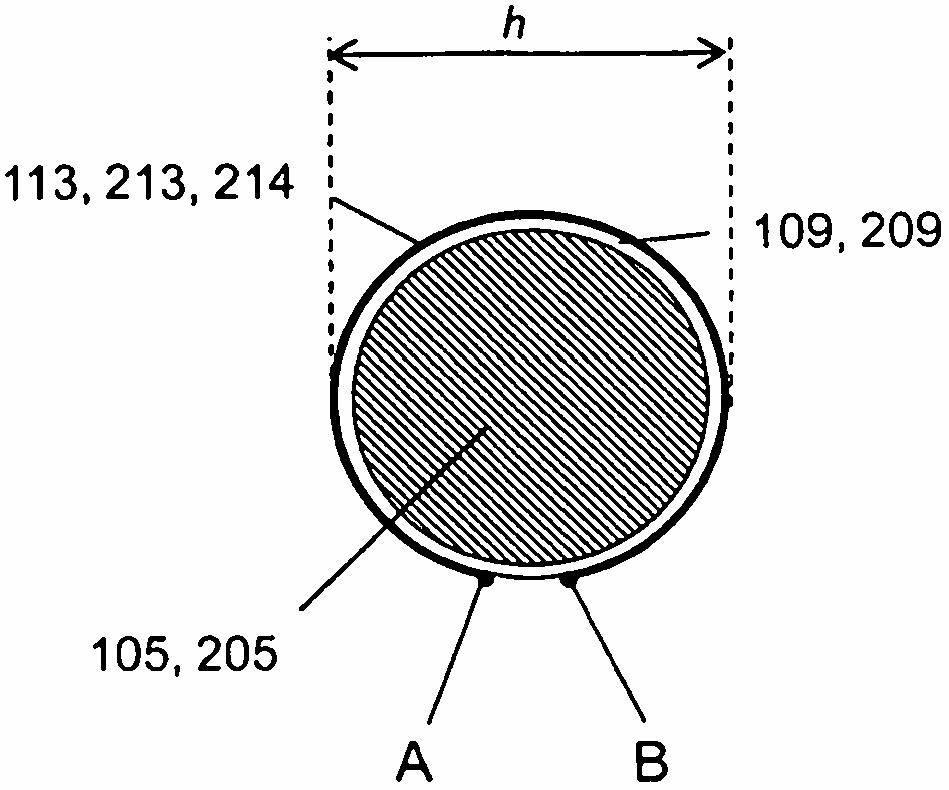

[0063] figure 1 A smoking article 101 is shown received in an electrically heated smoking system 103 according to a first embodiment of the invention. In this embodiment, the smoking article 101 has an elongated cylindrical shape and comprises an aerosol-forming substrate 105, a filter rod 107, the aerosol-forming substrate 105 and the filter rod 107 according to Arranged sequentially and aligned coaxially. Both parts 105 and 107 are wrapped by outer wrapping paper 109 . In this embodiment, the aerosol-forming substrate 105 is in the form of a cylindrical plug of solid substrate. The length l of the bung is substantially parallel to the length of the smoking article and also substantially parallel to the direction of airflow (not shown) in the electrically heated smoking system when a user smokes on the smoking article. The perimeter of the plug is substantially perpendicular to the length. The filter rod 107 is located at the downstream end of the smoking article 101, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com