Guide Assembly Tips for Droplet Spray Dental Cleaning Implements

A guide member, cutting-edge technology, applied in the field of guide assembly, can solve the problems such as not being able to easily see the rear teeth, difficulty in correctly seating the nozzle, improperly seating the nozzle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

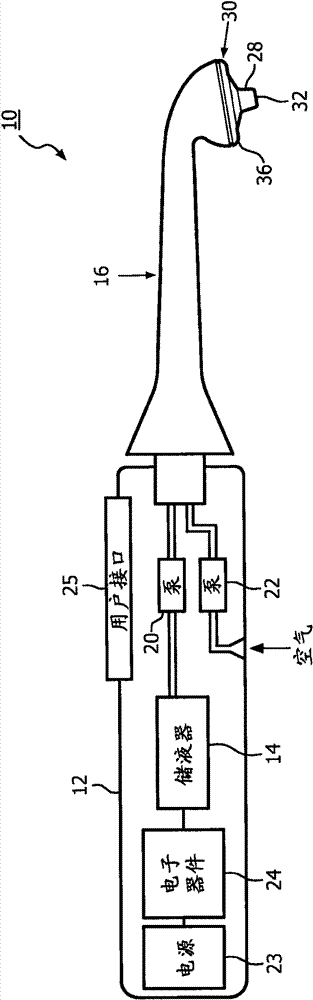

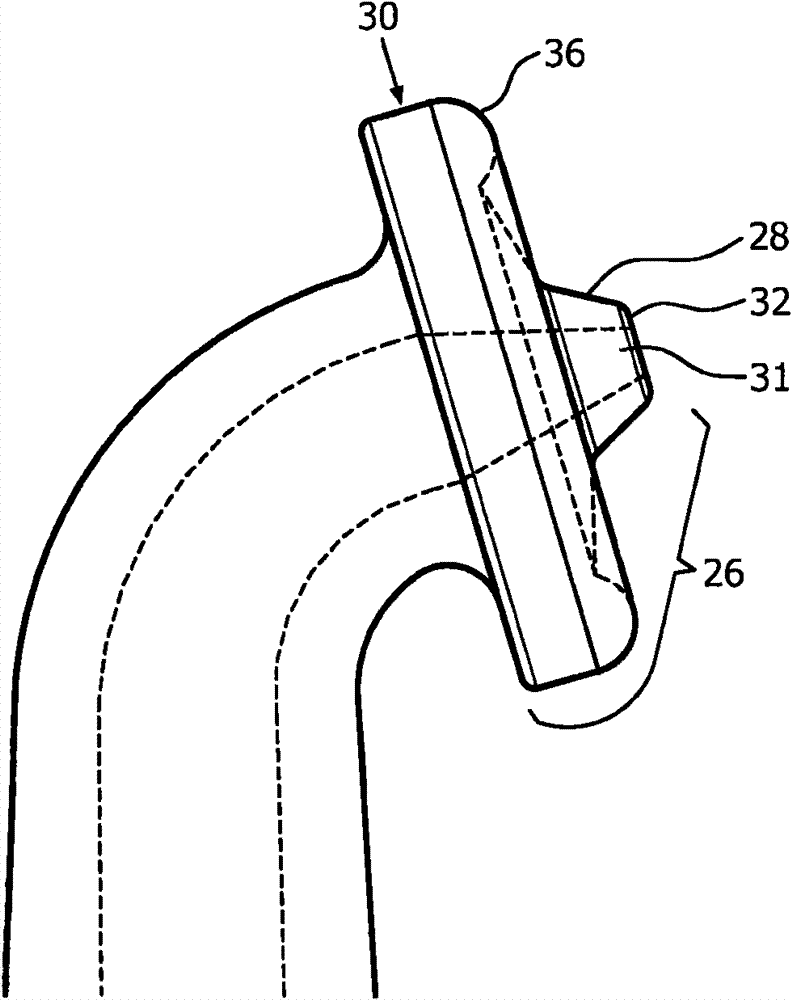

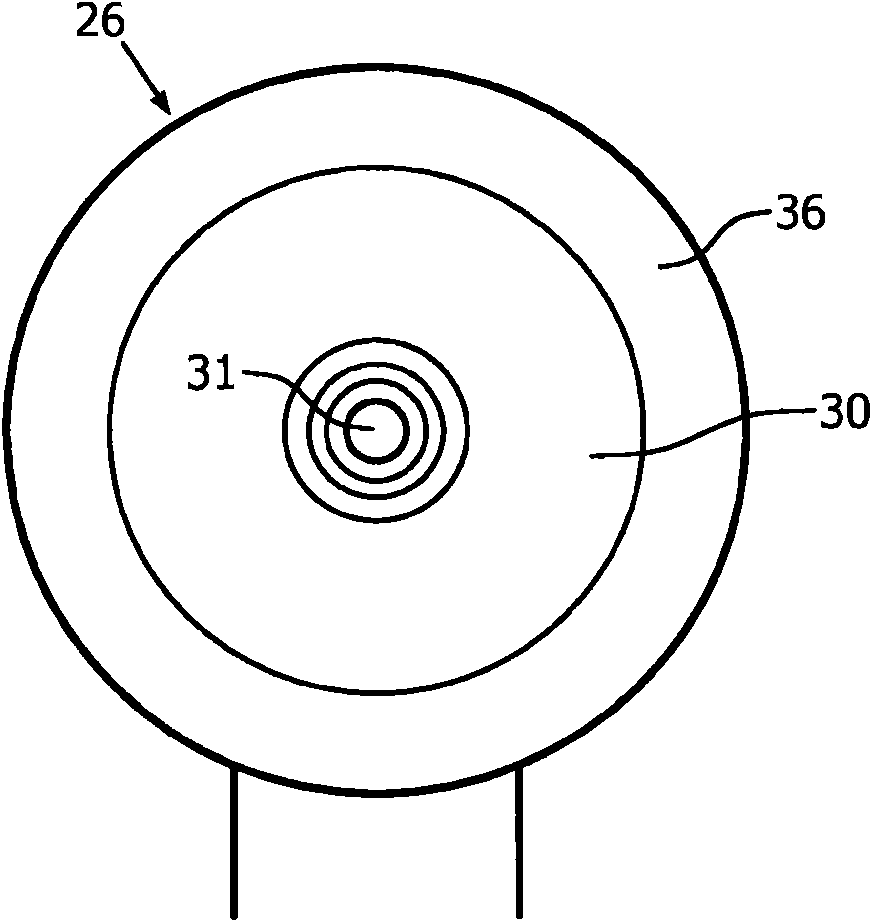

[0012] figure 1 A hand-held drop spray tooth cleaning implement is shown generally at 10 . A hand-held appliance suitable for domestic use includes a hand-held portion 12 in which a reservoir source of liquid 14 is located. In one embodiment, liquid such as water from the reservoir and air from the environment are directed by separate pumps 20 and 22 to the spout and guide assembly portion 16 of the appliance. The user interface 25 controls the actions of the appliance. Power is supplied by a power pack 23 such as a battery, while the appliance is controlled by a microprocessor (electronics) 24 . At the spout and guide assembly 16, the flow of gas (air) from the pump 22 generates droplets from the liquid supplied by the reservoir 14 and then accelerates the generated droplets to all points from the nozzle portion 30 of the appliance onto the teeth. Desired velocity of departure from a desired position on the tooth, in particular the interproximal area of the tooth.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com