A locating/guidance tip assembly for a liquid droplet spray teeth cleaning system

A technology for spraying systems and guiding components, applied in the direction of devices for cleaning dental cavities, etc., which can solve problems such as spray nozzles not being too close, damage to gums and other tissues, and efficiency decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

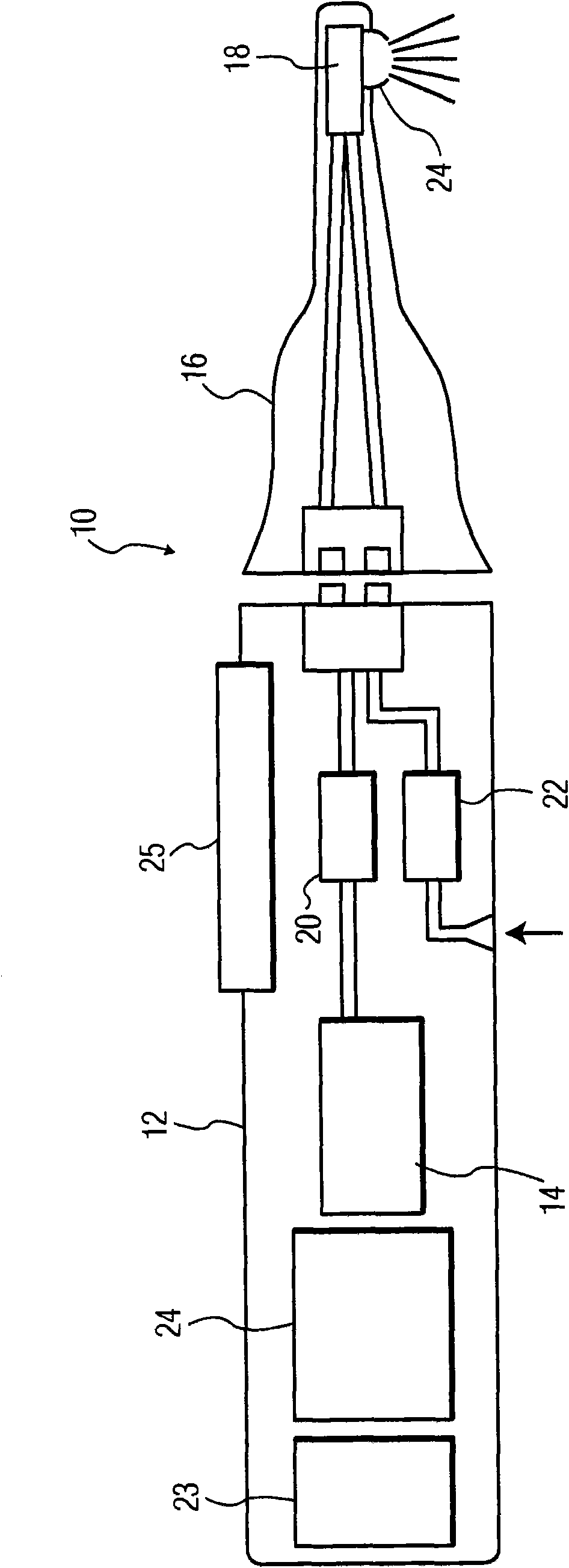

[0013] figure 1 A droplet spray dental cleaning system 10 is shown generally. A typical handheld system for home use will include a body or handle portion 12 with a liquid source 14 positioned therein. In one arrangement, gas and liquid are moved to the head 16 of the system by pumps 20-22. The liquid and gas are directed into the nebulizer assembly 18 where the gas flow creates and accelerates the droplets to the desired velocity as they exit the nozzle 24 at the end of the head to the desired location on the tooth.

[0014] In one example, the droplets range in size from 10-15 mm and are accelerated to a velocity of approximately 30 meters per second. However, other arrangements with different sized droplets and different velocities may be used, eg a maximum velocity of 70 meters per second. In this embodiment, the head 16 is arranged to be replaceable with respect to the handle portion which includes the liquid and gas supply, the electronic control 24 and the system pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com