Film riding seal for turbines

A technology for seals and turbines, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc., and can solve the problems that seals have not been widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

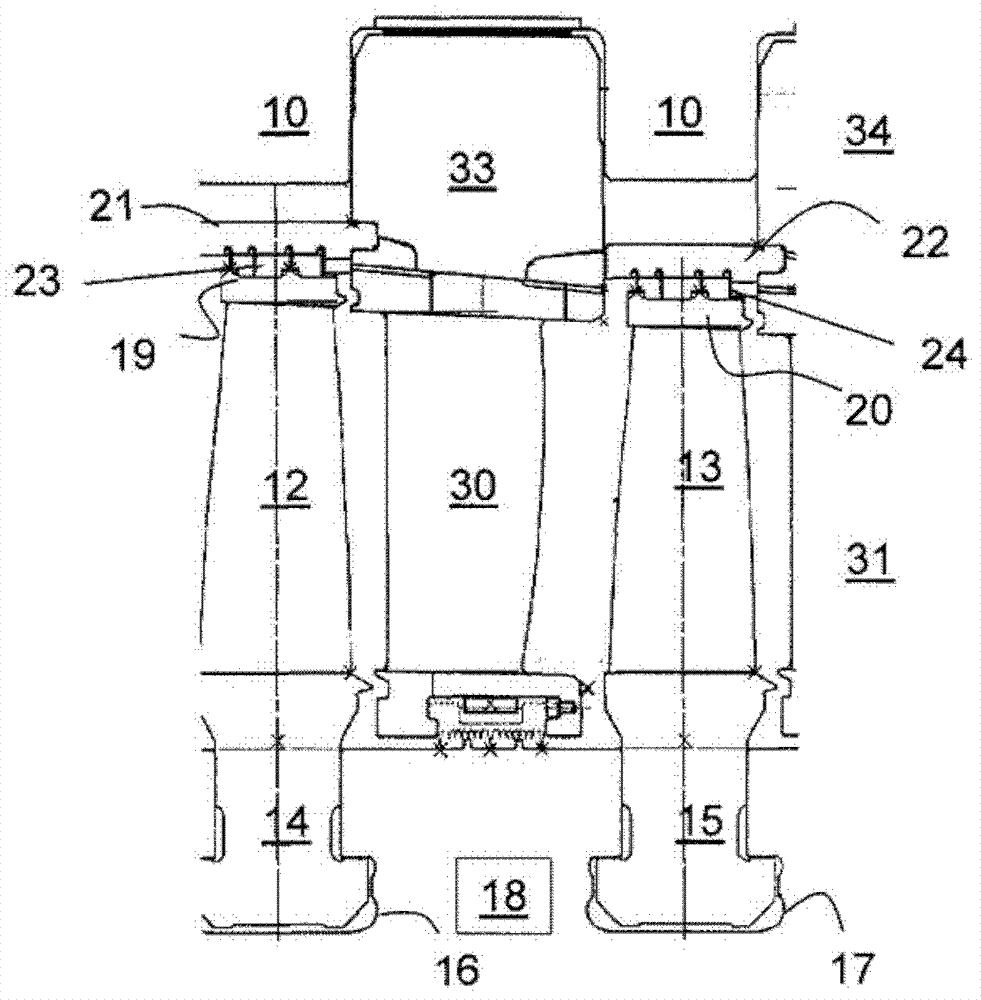

[0031] First, details of aspects and examples of the present invention are described in greater detail in the following description relating to the so-called "compact diaphragm" design as shown in Figure 1, which reproduces commonly-owned published U.S. Patent Application No. 2008 Relevant features of Figure 2 in / 0170939.

[0032] A partial radial cross-sectional sketch of an axial flow turbine is shown in Figure 1 , showing the section of a ring of stationary blades or diaphragms located between successive annular rows of moving blades 12, 13 in a steam turbine. The moving blades are each provided with a radially inner “T-root” portion 14 , 15 which sits in a corresponding slot 16 , 17 machined in the edge of the rotor drum 18 . Their ends are also provided with radially outer members called caps 19 , 20 . In the example shown, the cover carries the moving parts of the labyrinth seal. Delimited segmented rings 21, 22 support the stationary part of the seal. They are rigid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com