Reinforcing construction method for H-shaped steel line

A construction method, H-shaped steel technology, applied in roads, laying tracks, erecting/assembling bridges, etc., can solve the problems of poor ability to resist accidents and limit the scale of roads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

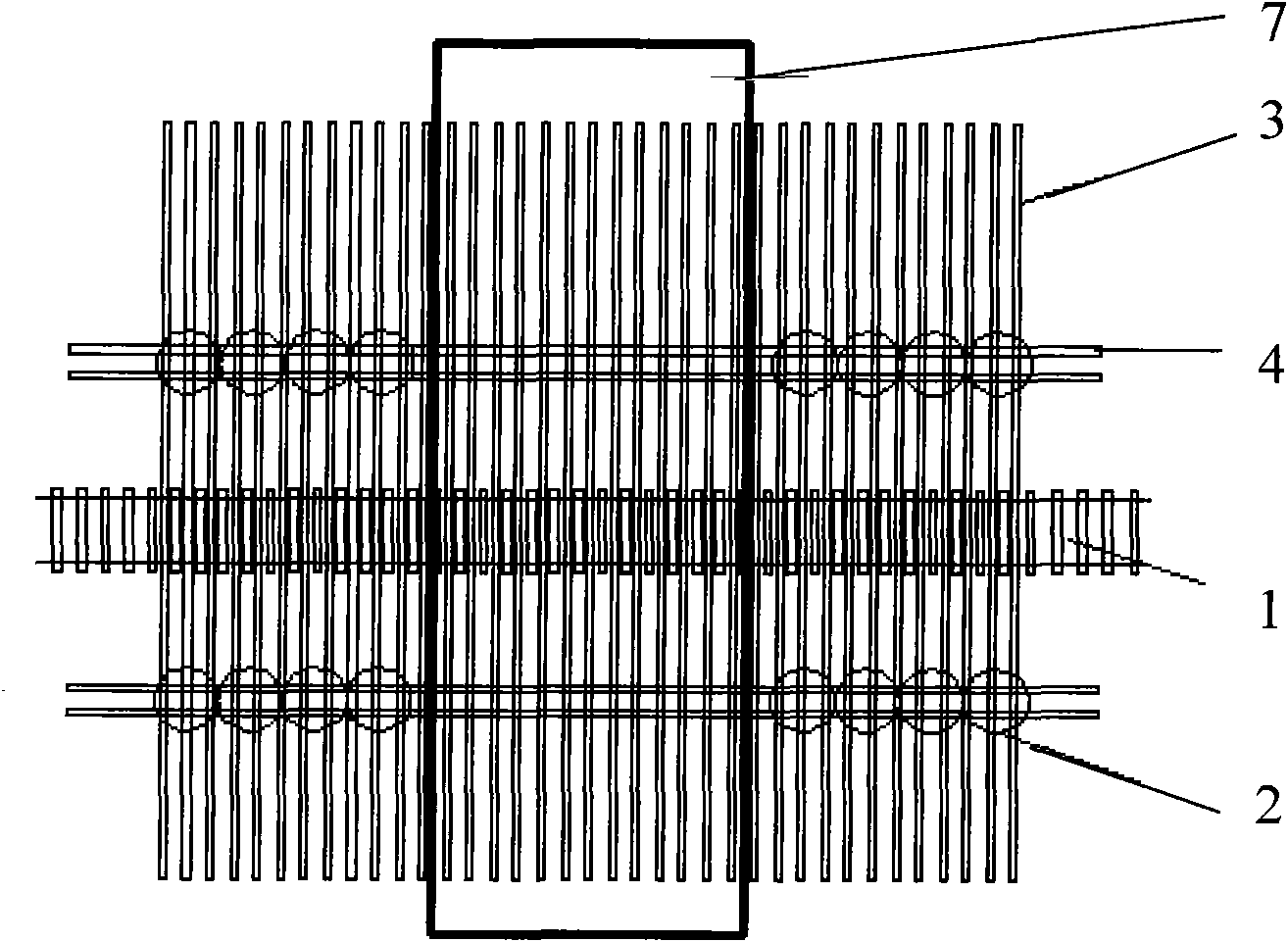

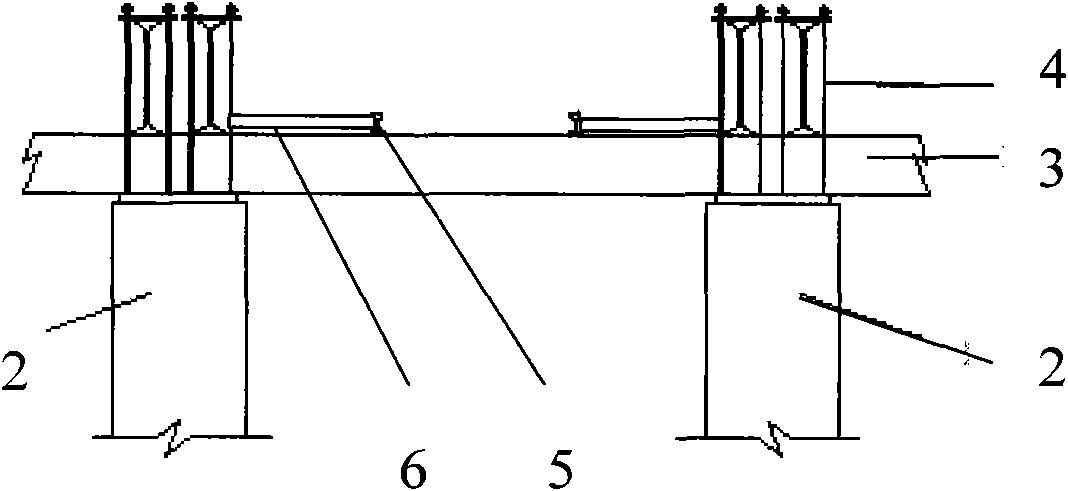

[0018] Such as figure 1 figure 2 As shown, the H-shaped steel line reinforcement construction method includes the following steps:

[0019] One. Build four groups of deep foundation piles 2 on both sides of the existing railway line 1, two groups on each side, and each group includes a plurality of deep foundation piles arranged in the same direction as the railway;

[0020] 2. A crossbeam I-beam 3 is installed between each sleeper space below the railway line 1, so that the crossbeam I-beam 3 vertically crosses the railway line 1 and straddles the deep foundation piles 2 on both sides of the railway. Before the I-beam 3, the ballast in the space between the sleepers must first be dug to pass through the beam I-beam 3; and the distance between the existing sleepers should be adjusted; The space between the beam I-beam 3 on the four-corner deep foundation pile 2 and the deep foundation pile 2 is filled with planks and wooden wedges;

[0021] 3. Above the two groups of deep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com