Device for measuring concentration distribution of single-element or multi-element particle system

A concentration distribution and multivariate technology, which is applied in the direction of analyzing materials and instruments, can solve the problems of being easily affected by gas-solid two-phase flow pulsation and uneven flow field, increasing the randomness of sampling results, and failing to meet measurement requirements, so as to avoid Error, simple structure, cheap cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

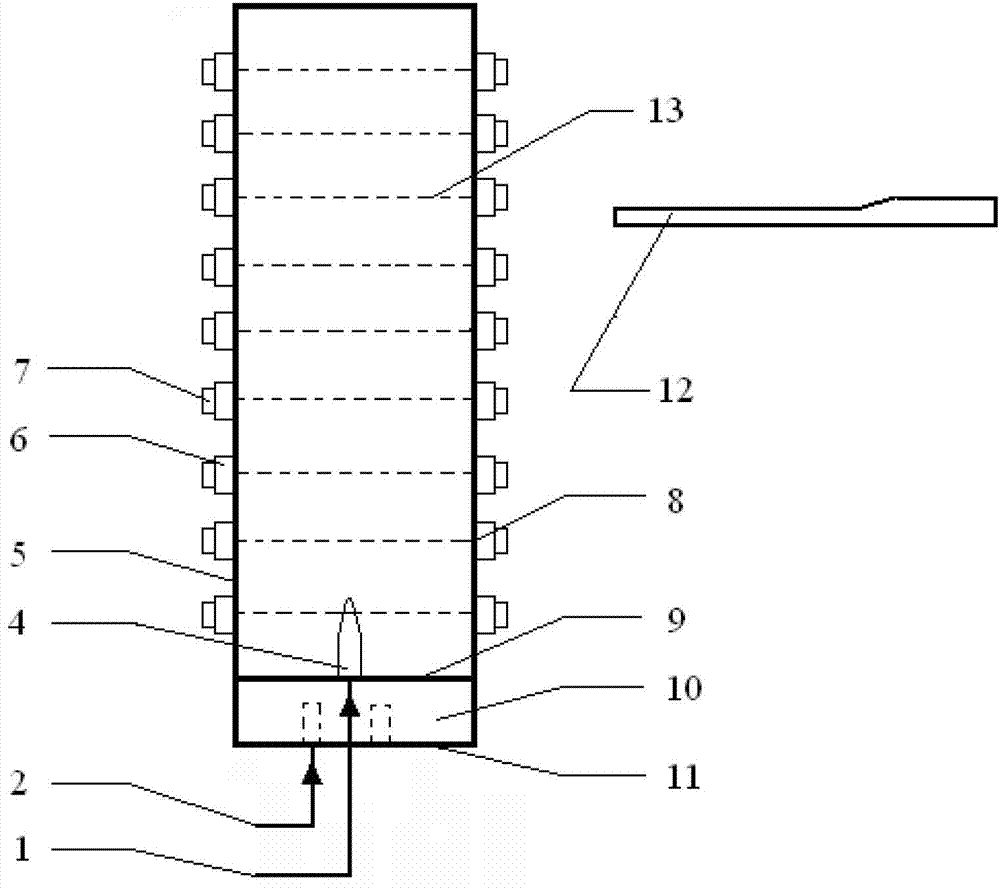

[0022] The present invention provides a device for measuring the concentration distribution of a unit or a multi-element particle system in a fluidized bed. The present invention will be further described below with reference to the drawings and specific embodiments.

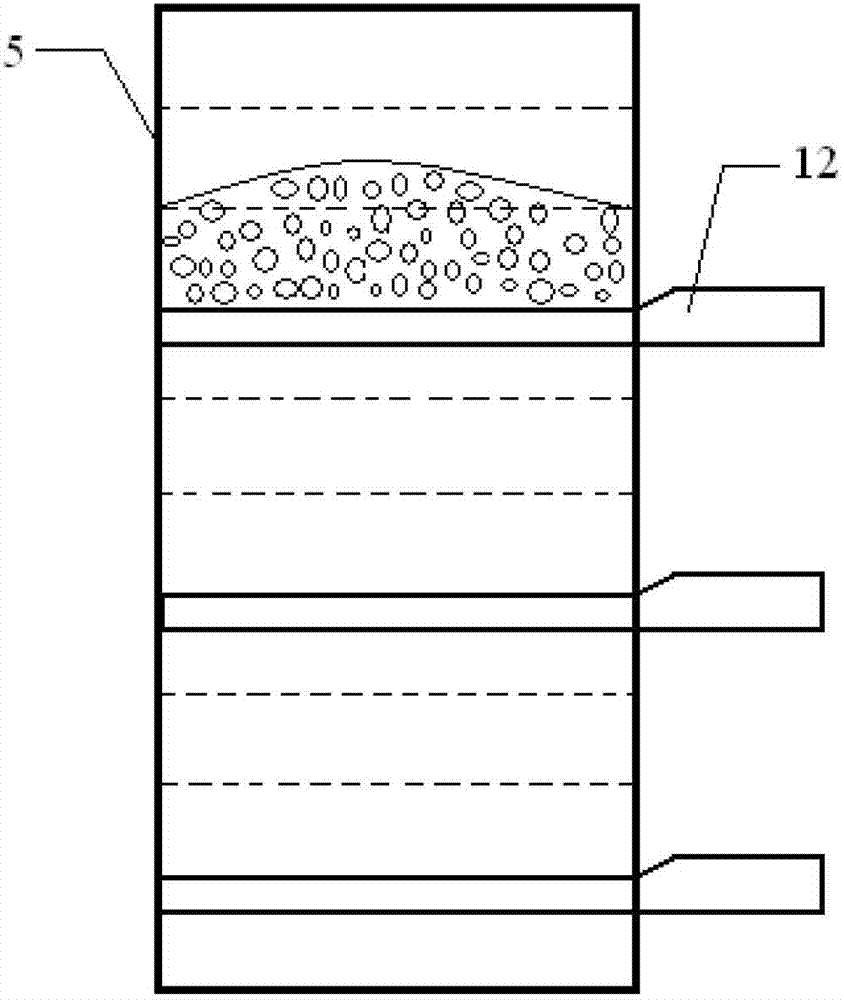

[0023] The structure of the present invention is as figure 1 As shown, the multi-layer side wall discharge ports 8 are evenly arranged on the two side walls of the main fluidized bed 5; the inner wall of the main fluidized bed 5 at the side wall discharge ports 8 of each layer is respectively provided with guide rails 13 and Install the take-off partition plate 12 on the guide chute 13; the lower part of the main fluidized bed 5 is divided into the gas pre-distribution chamber 10 by the gas distribution plate 9, and the bottom of the main fluidized bed 5 is the bottom distribution plate 11; In the pre-distribution chamber 10, the bottom distribution plate 11 is provided with an annulus inlet pipe 2, and a jet inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com