Grading seabed pipeline construction method via ditching twice and stopping bending through preheating

A submarine pipeline and construction method technology, which is applied in pipeline protection, pipeline laying and maintenance, pipeline heating/cooling, etc., and can solve the problems of difficult inspection and maintenance and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

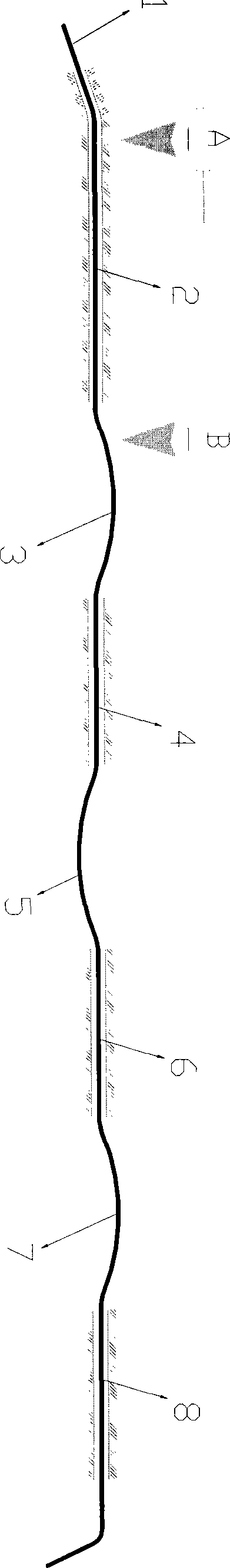

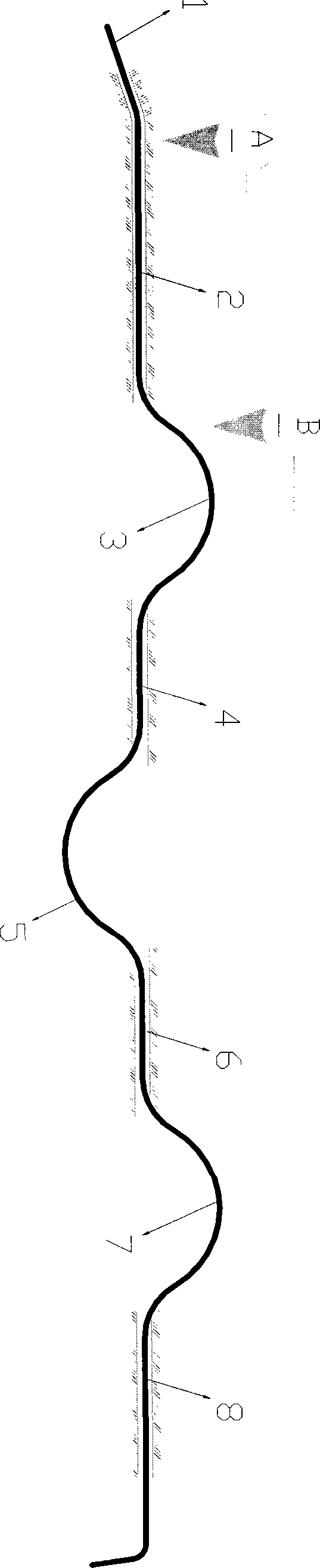

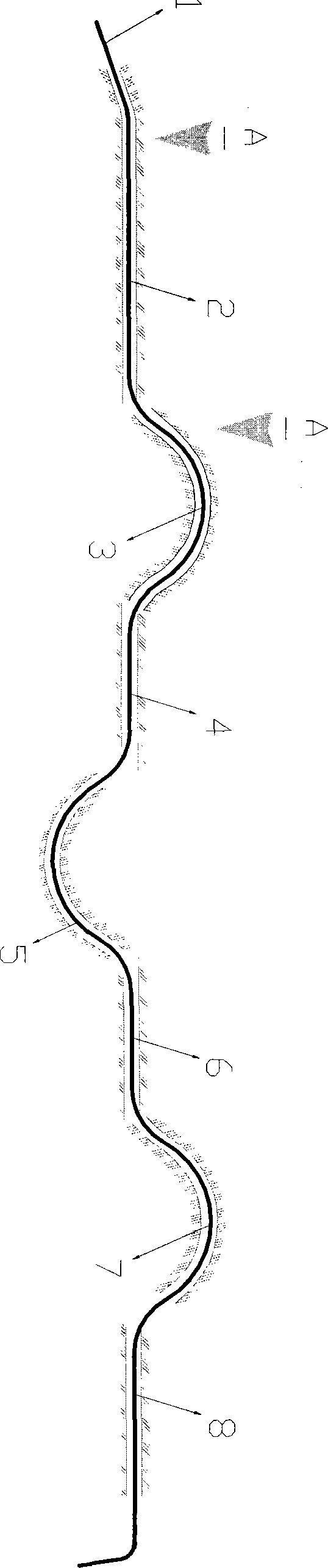

[0012] like figure 1 As shown, during the laying process of the submarine pipeline, the pipeline sections at positions 3, 5, and 7 are laid on the seabed in an arc, and these three sections of pipeline are used as reserved pipeline sections, and trenches are dug and immersed in other locations of the pipeline. The reserved lengths of the three sections 3, 5, and 7 of the pipeline should meet the following two conditions: ①Only lateral buckling of the first-order mode generally occurs in the pipeline section under this length; ②The lateral buckling of the pipeline section after preheating The wavelength is long enough, the buckling amplitude is not too large, the process occurs slowly, and the induced stress concentration is acceptable. Therefore, the reserved length of the three sections 3, 5, and 7 should be calculated in advance according to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com