Operation shop bottleneck recognition method based on cluster analysis and multiple attribute decision making

A technology of multi-attribute decision-making and cluster analysis, which is applied in the field of bottleneck identification of job workshops based on cluster analysis and multi-attribute decision-making, can solve the problems of no scientific basis, less research on multi-bottleneck identification, and no scientific basis for multi-bottleneck division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

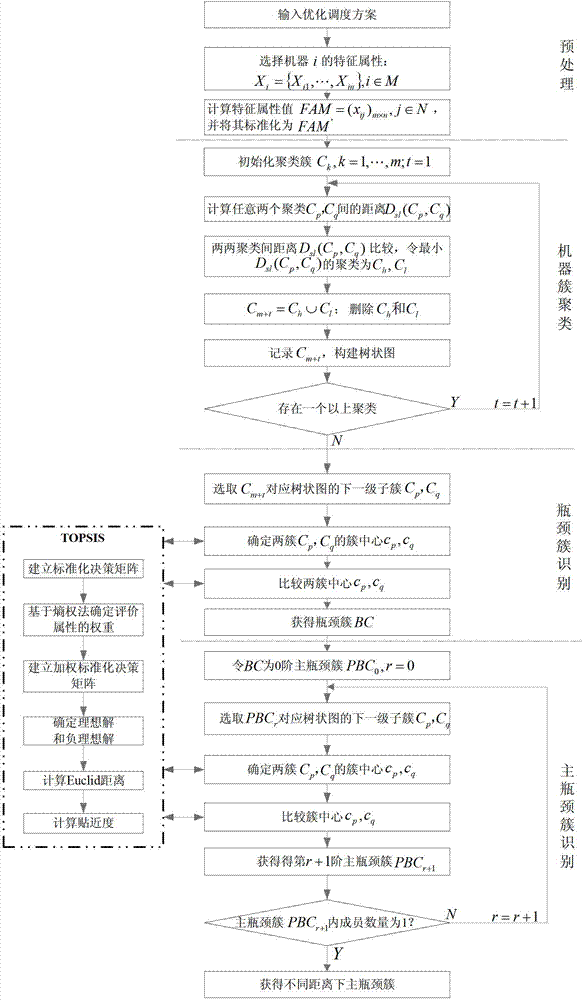

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is mainly used in the production control process of the work workshop. The method of the present invention identifies the work bottleneck, so that the dispatcher can reasonably pay attention to the bottleneck resource and the non-bottleneck resource, improve the efficiency of the production organization, and maximize the utilization of the production capacity of the workshop. Improve economic efficiency.

[0055] The determination of the bottleneck machine should comprehensively consider the various attributes of the machine. The bottleneck identification process is defined as the process of obtaining bottleneck clusters through comprehensive judgment and decision-making based on bottleneck feature attributes.

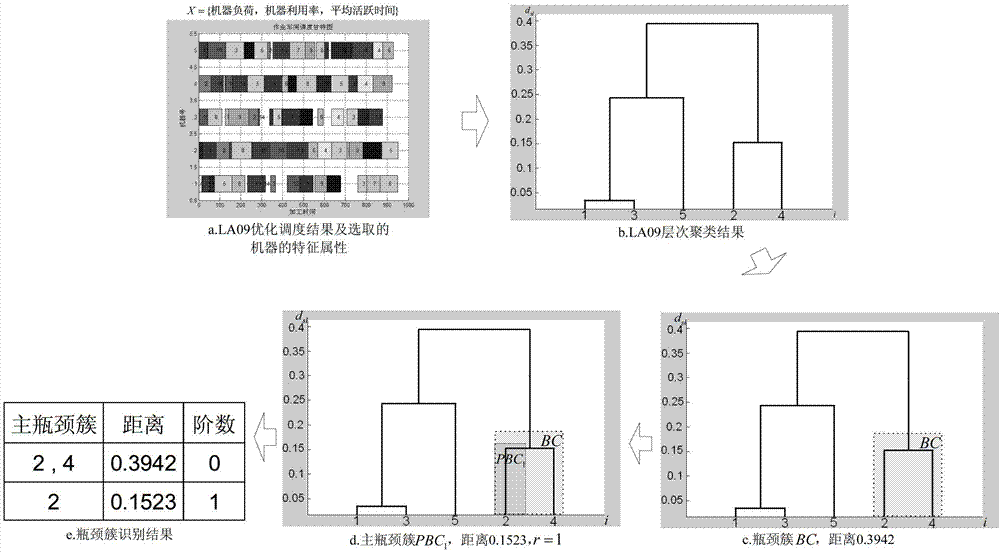

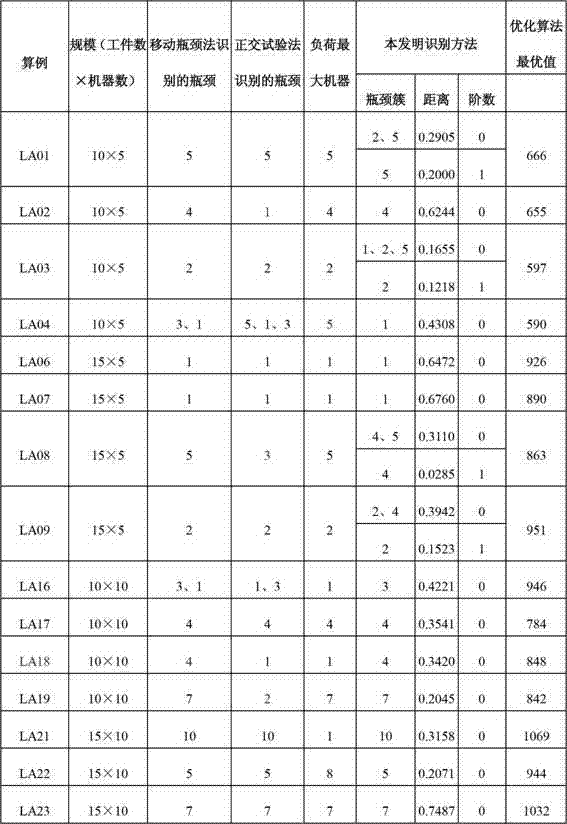

[0056] In this embodiment, the standard example LA09 of the JSSP problem LA class is selected to illustrate the bottleneck cluster identification process. Use the immune evolution algorithm in advance to optimize and solve the LA09 standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com