High-temperature-resistant solid-film lubricant coating

A technology of lubricating coatings and solid films, applied in the direction of lubricating compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

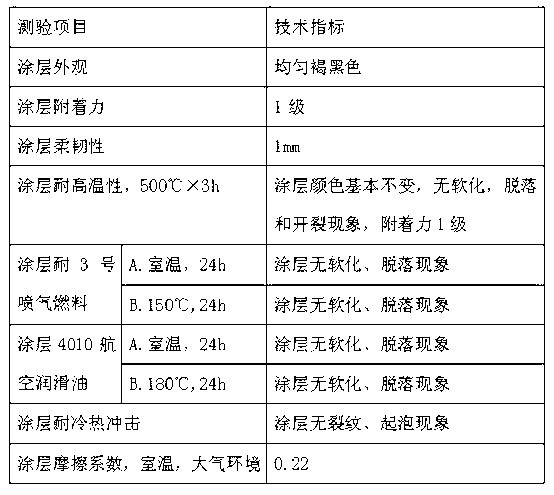

Image

Examples

Embodiment 1

[0022] Composition of solid film lubricating coatings:

[0023] Silicone resin 50g;

[0024] Graphite 40g;

[0026] Mixed solvent 65ml.

[0027] The above-mentioned graphite and metal oxide are baked at 200° C., and then the silicone resin and solvent are mixed together, poured into a ball mill jar for ball milling, and mixed uniformly to obtain a lubricant. After the lubricant is coated, it needs to be heated and cured by stepwise heating at 150°C, 200°C, and 250°C, and finally a solid coating with a thickness of 15 μm is obtained.

Embodiment 2

[0029] Composition of solid film lubricating coatings:

[0030] Silicone resin 40g;

[0031] Graphite 45g;

[0033] Mixed solvent 70ml.

[0034] The above-mentioned graphite and metal oxide are baked at 200° C., and then the silicone resin and solvent are mixed together, poured into a ball mill jar for ball milling, and mixed uniformly to obtain a lubricant. After the lubricant is coated, it needs to be heated and cured by stepwise heating at 150°C, 200°C, and 250°C, and finally a solid coating with a thickness of 20 μm is obtained.

Embodiment 3

[0036] Composition of solid film lubricating coatings:

[0037] Silicone resin 60g;

[0038] Graphite 25g;

[0039] Chromium oxide 15g;

[0040] Mixed solvent 40ml.

[0041] The above-mentioned graphite and metal oxide are baked at 200° C., and then the silicone resin and solvent are mixed together, poured into a ball mill jar for ball milling, and mixed uniformly to obtain a lubricant. After the lubricant is coated, it needs to be heated and cured by stepwise heating at 150°C, 200°C, and 250°C, and finally a solid coating with a thickness of 4 μm is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com