Pipe guide arms for blind shear rams

一种引导臂、闸板的技术,应用在密封/封隔、井眼/井部件、土方钻采等方向,能够解决管柱不完全剪切等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

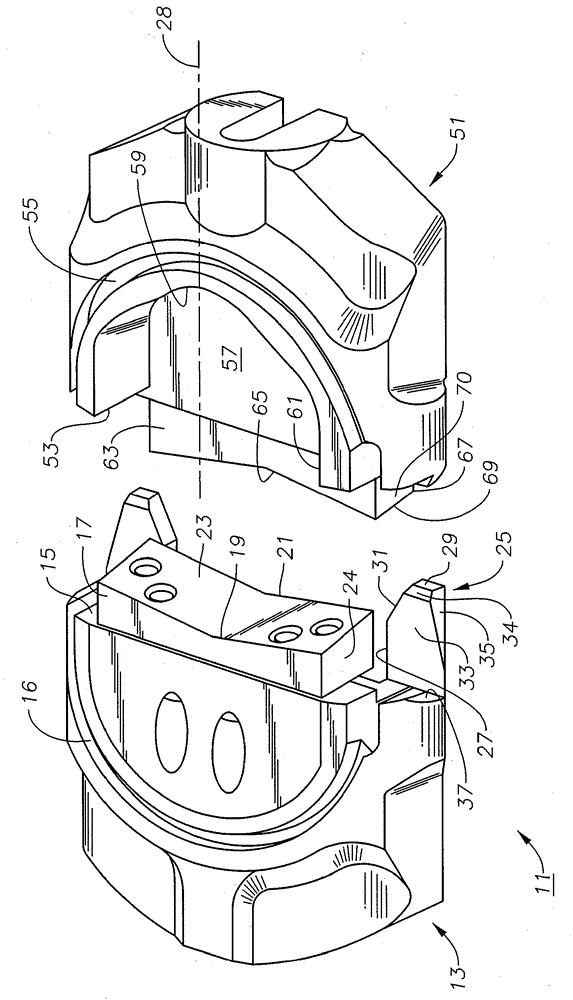

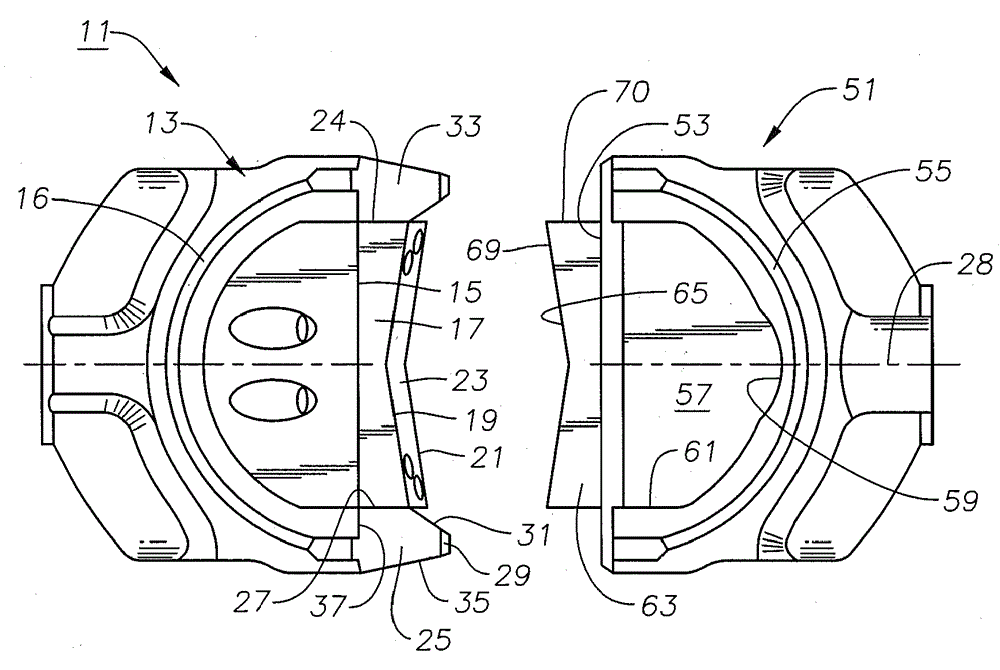

[0017] refer to figure 1 , shows the shear ram 11 removed from the housing or bonnet in which the shear ram 11 is located. The shear ram 11 is part of a ram BOP assembly which is part of a stack assembly. In the case of offshore drilling, the stack assembly is located at the lower end of a riser extending down from the drill ship. The lower end of the BOP stack assembly is secured to the subsea wellhead on the seabed. The BOP stack assembly will also typically contain pipe rams, variable aperture rams, and a quick disconnect mechanism for disconnecting from the riser in an emergency. When actuated, the shear ram 11 will close the through-bore and also shear tubing in the well, such as drill pipe, tubing or tubing string.

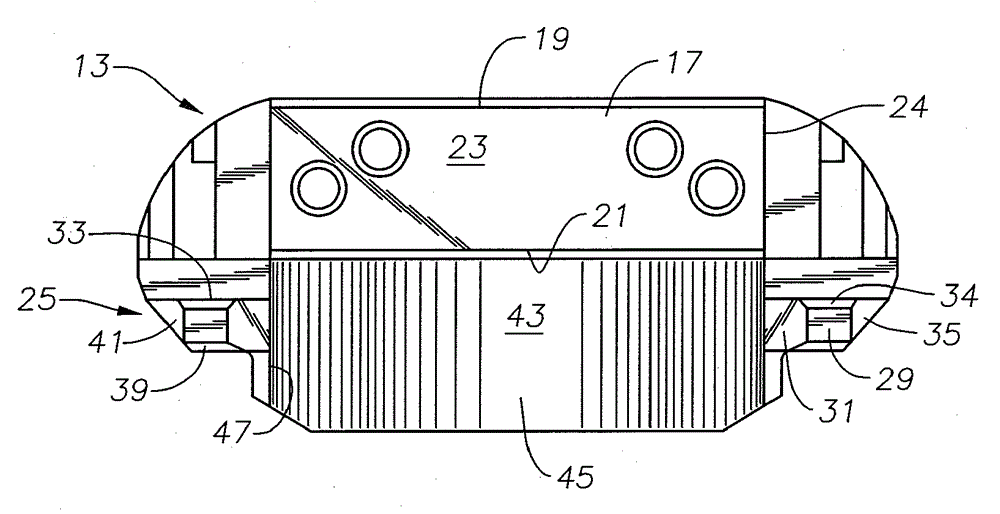

[0018] The shear ram 11 includes an upper ram assembly 13 having a face or front end 15 . A semicircular sealing groove 16 is located on the upper side of the upper shutter unit 13 to receive a portion of the elastomeric seal. An upper shearing blade 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap