Integral carrier

A one-piece, bracket technology, applied in the field of brackets, can solve problems such as heavy workload, weak connection, damage to brackets and bracket plates, etc., and achieve the effects of prolonging service life, firm brackets, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

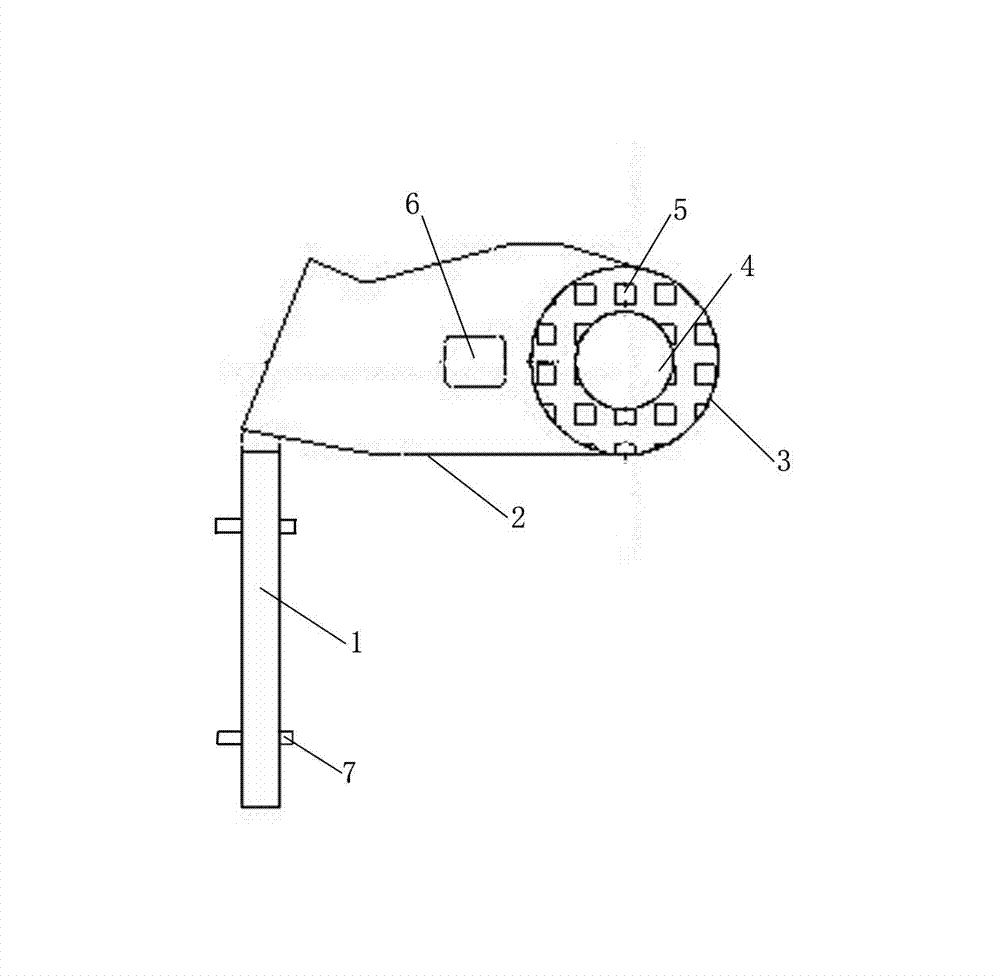

[0009] In order to further reveal the technical solutions of the present invention, the following describes the implementation of the present invention in detail in conjunction with the accompanying drawings: figure 1 As shown, the one-piece bracket includes a bracket 1 and a bracket flat plate 2 perpendicular to the bracket 1. The bracket 1 and the bracket flat plate 2 are integrally connected to make the bracket stronger and prolong the service life of the bracket. Easy to install and remove. One end of the frame plate 2 is shaped like a ring 3, the center of the ring 3 is a circular hollow 4, surrounded by a plurality of rectangular hollows 5, and the center of the frame plate 2 is provided with a rectangular hollow 6. The bracket 1 is provided with mounting screws 7 for fixing the bracket 1 on the wall.

[0010] Through the introduction of the listed embodiments above, the basic ideas and basic principles of the present invention have been explained. However, the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com