Process for the preparation of a solid metallocene catalyst system and its use in polymerisation of olefins

一种烯烃聚合、催化剂的技术,应用在制备固体金属茂催化剂体系以及该催化剂体系在烯烃聚合中的应用领域,能够解决降低催化剂体系形态学、预聚合增加成本、结片等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0291] Example 1: Preparation of liquid clathrates; variant B

[0292] 250 mg of racemic cyclohexyl(methyl)silanediyl-bis(2-methyl-4-(4'-tert-butylphenyl)indene- 1-yl) zirconium dichloride was reacted with 15 mL of 30 wt% MAO solution in toluene to form a catalyst solution. Al / Zr is 370 mol / mol.

[0293] 0.97 mL of clathrate reagent octamethyltrisiloxane (OMTS) was added to this solution, and the solution thus obtained was placed in a glove box overnight while mixing. After adding OMTS, the red mixture turned orange. On day 2, mixing was stopped and the liquid separated into a toluene phase and a catalyst phase. Use 5 mL of bottom catalyst phase. The liquid has now changed its color to dark red, and the top phase also has a reddish color.

Embodiment 2

[0294] Example 2: Preparation of liquid clathrates; variant A

[0295] 0.97 mL of the clathrate reagent octamethyltrisiloxane (OMTS) was added to 15 mL of a 30 wt% MAO solution in toluene, and the resulting slurry was stirred overnight. Stirring was then stopped and two separate phases formed. Discard the upper phase.

[0296] Add 5 mL of the lower layer containing the clathrated MAO to 179 mg of racemic cyclohexyl(methyl)silanediyl-bis(2-methyl-4-(4'-tert-butylphenyl)indene-1 - base) zirconium dichloride. The resulting solution was stirred for 1 hour and had a dark red color.

[0297] Al / Zr is 235 mol / mol.

Embodiment 3

[0299] 5mL of the catalyst solution prepared according to Example 1 was added into a 30mL GPL 106 in a 50 mL emulsion glass reactor equipped with "open baffles" and a stirrer suspended below the oil surface. Mixing was then started for 15 minutes with a tip speed of 0.75 m / s (mixing speed 250 rpm).

[0300] Argon was then turned on to evaporate the toluene. The residual catalyst / oil slurry was siphoned into a septum bottle with argon flushing continued for 120 minutes before mixing was stopped.

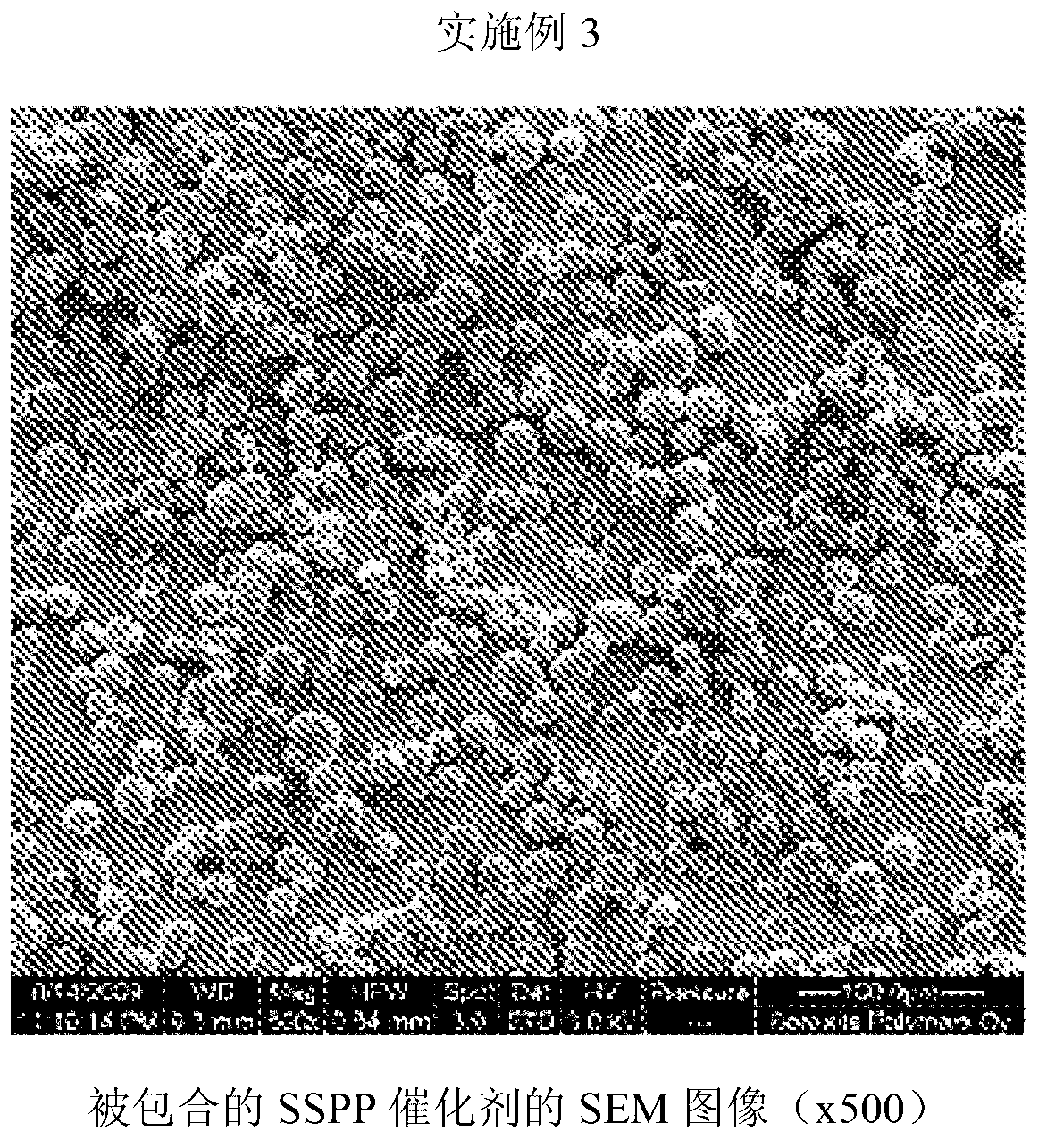

[0301] catalyst

[0302] PSD: 5-15μm (based on SEM image)

[0303]The catalyst productivity was 5 kgPP / g catalyst·h.

[0304] from figure 1 with figure 2 As can be seen in , perfectly spherical particles with smaller particle sizes are formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com