Graphene modified phenolic resin, preparation method thereof and application of graphene modified phenolic resin in preparation of composite material

A graphene modification and phenolic resin technology, applied in the field of phenolic resin modification, can solve the problems of high curing temperature, poor mechanical properties, and high brittleness of phenolic resin, and achieve excellent mechanical properties, reduce curing temperature, and increase activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

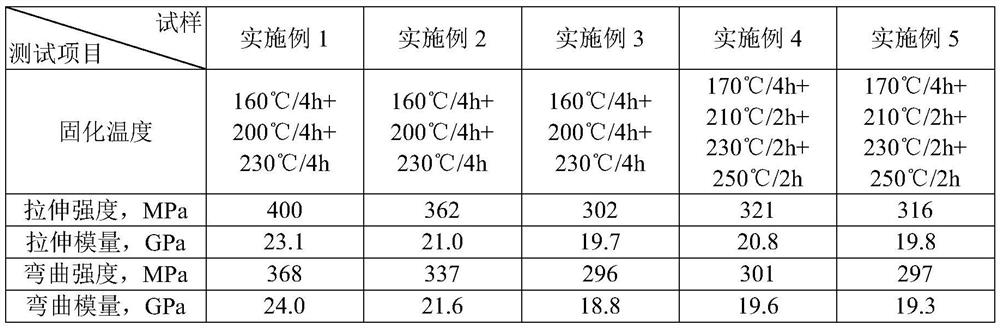

Examples

preparation example Construction

[0022] As described above, in a first aspect the present invention provides a method for preparing a graphite-modified phenolic resin, said method comprising the steps of:

[0023] (1) The graphene is added to butanol and mixed uniform, and a graphene solution is obtained;

[0024] (2) Melting the phenolic resin to give a melted phenol resin;

[0025] (3) Add the melted phenolic resin to the graphene solution and mix well to obtain a composite solution;

[0026] (4) The composite solution is warmed and ultrasonically dispersed to obtain a dispersion;

[0027] (5) Heat the dispersion to complete modification reactions while removing the solvent to obtain a modified phenol resin.

[0028] The present invention is not particularly limited phenolic resin employed, may be a novolak, a phenol may be a body. Preferably, the molecular weight of the phenolic novolak resin is 500 to 8,000 in.

[0029] In some preferred embodiments, the graphene graphene powder, and prepared by a process com...

preparation example 1

[0062] Preparation of graphene

[0063] 1.1 Preparation of oxide oxide

[0064] Take an improved Hummer method prepared oxide oxide: 20 g of natural graphite powder, 10 g of potassium sulfate and 10 g of phosphorus 1 to 80 ° C 2 SO 4 (In 70% by mass), stir evenly, cool over 6 h, washed to neutral, dry. Add the dried product to 0 ° C, 230 ml thick h 2 SO 4 (The concentration is 70% by mass) and mixed uniform, then 60 g of potassium permanganate is added and uniformly mixed. The mixture was raised to 20 ° C, then in an oil bath of 35 ° C for 2 hours, 920 ml of deionized water was added. After standing for 15 minutes, 2.8 L of deionized water (which contains 50 ml of hydrogen-containing hydrogenly, the concentration of 30% by mass), after the mixture color became bright, hot filtration, and then 5 l concentration of 10% by mass The dilute sulfuric acid was washed 3 times, and the oxide oxide was obtained.

[0065] 1.2 Preparation of graphene powder

[0066] 0.5 g of the above-made o...

preparation example 2

[0070] The same manner as the preparation example 1 is carried out, and the alcohol is replaced by the same acetic acid (a boiling point is 118 ° C) using an equal volume of acetic acid (boiling point is 118 ° C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com