Arc-shaped cutting stitching instrument

A suturing device and an arc-shaped technology, applied in the field of arc-shaped cutting suturing devices, can solve the problems of staple resistance, small size, and incorrect formation of staples, and achieve the effects of good staple forming, convenient assembly and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

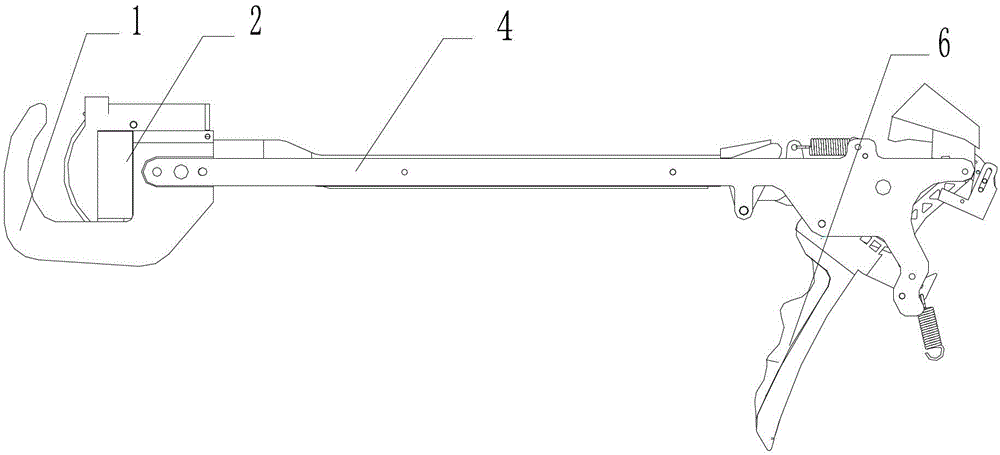

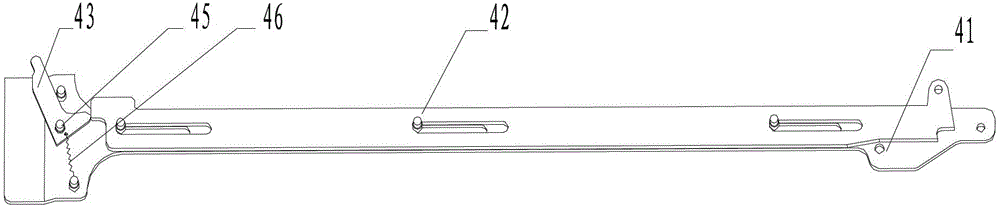

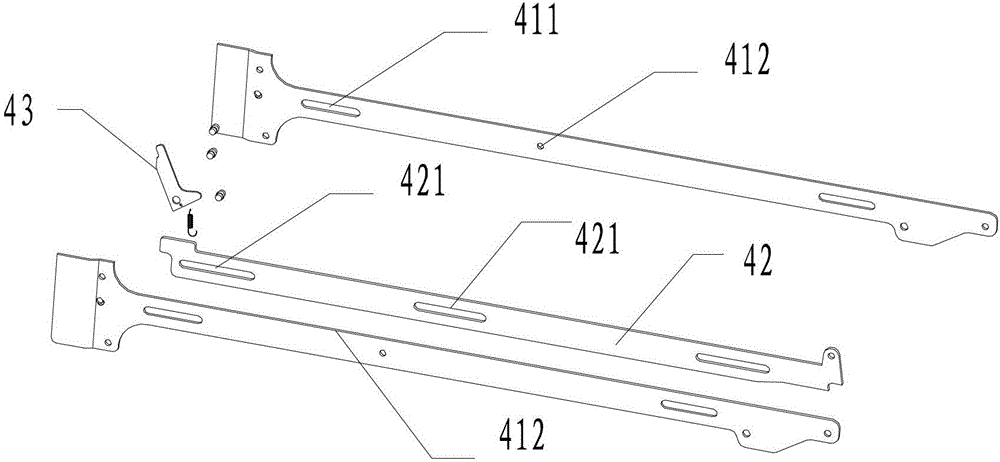

[0033] see figure 1 As shown, an arc-shaped cutting stapler of the present invention is based on the structure of the existing cutting stapler support plate, jaw support 1, staple cartridge assembly 2, nail abutment seat, connecting assembly 4, propulsion mechanism and firing mechanism 6 Above, design the surface of the staple anvil and the staple cartridge body of the staple cartridge assembly 2 as an arc, and design the connection and installation method among the bracket plate, component splint, and nail pusher plate as a matching structure between the chute and the pin, and in the assembly A cutting knife shifting block is installed at the front end of the splint to drive the cutting knife to move along the arc-shaped staple bin.

[0034] In order to describe the structural features of the present application more clearly, the direction of travel of the connecting assembly during the jaw closing process (i.e. figure 1 shown on the left) is "front" and its opposite directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com