Nail pushing sliding block of anastomat

A stapler and slider technology, applied in the field of medical devices, can solve the problems of reducing friction, increasing device firing force, increasing friction force, etc., and achieves the effects of simple structure, convenient manufacture and reduction of firing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

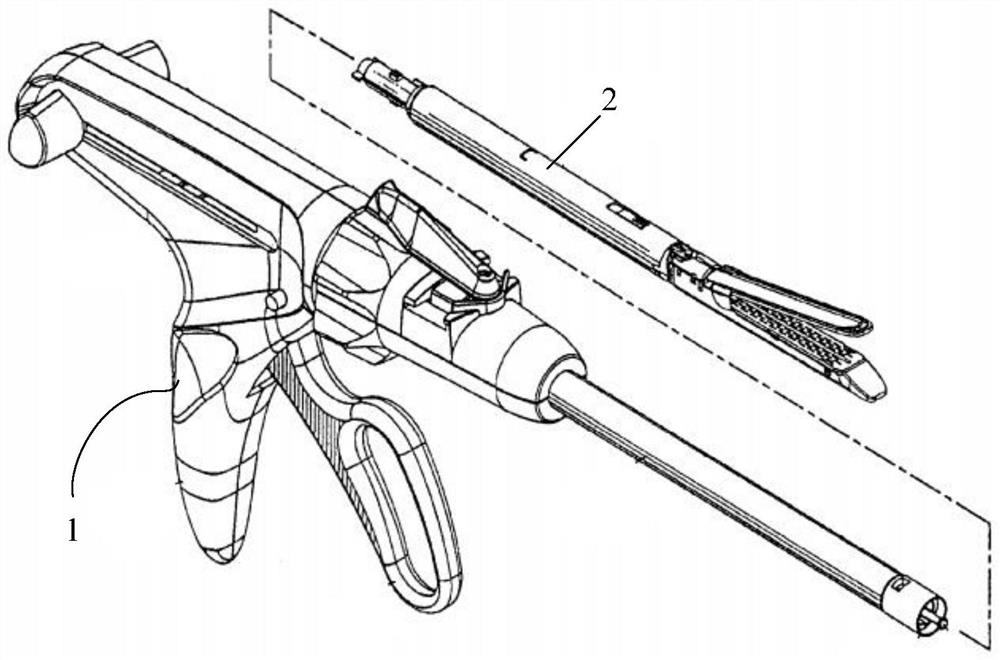

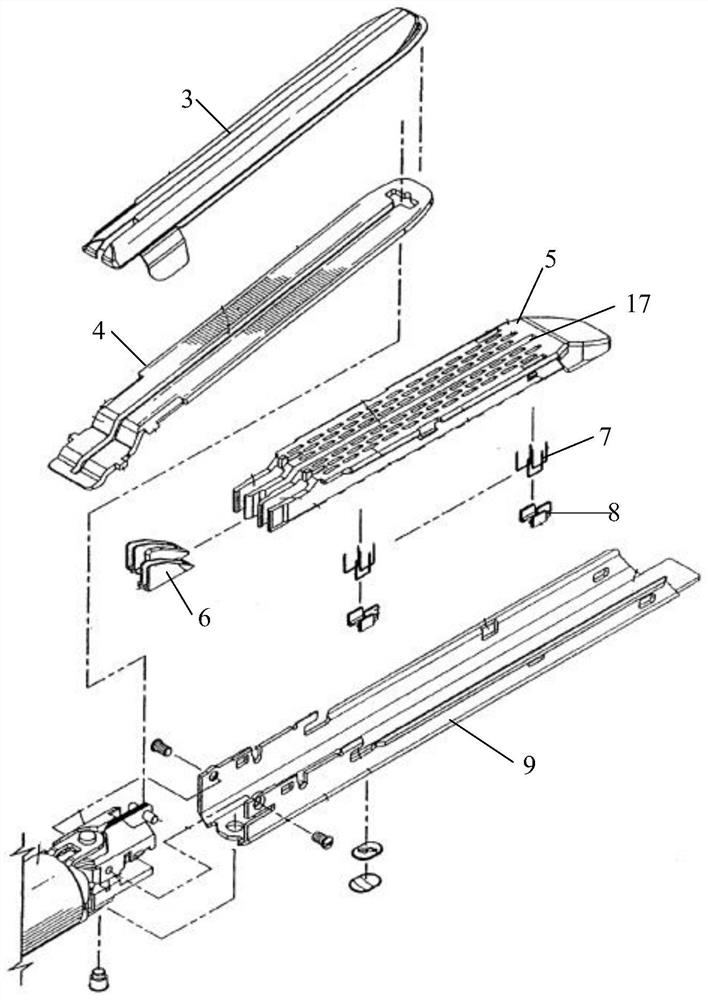

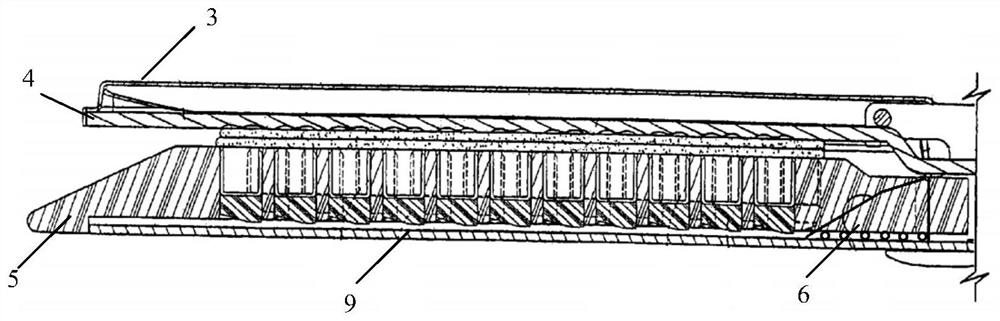

[0030] Figure 1-8 As shown, on the one hand, this embodiment discloses a stapler pusher slider, the bottom of the stapler slider 6 is provided with several cylindrical rollers 11 perpendicular to its moving direction, the rollers 11 and the stapler The inner surface of the nail box base 9 on the top is matched, and the nail pushing slider 6 has a working surface with a slope feature, and several cylindrical working rollers 10 are arranged on the working surface, and the working rollers 10 and the pushing nails on the stapler The lower end slope of the stapler 8 is matched, and the nail pushing slider 6 is also provided with a rolling module that matches the long groove 17 provided on the staple bin 5 on the stapler. When moving in the direction of the longitudinal axis, rolling friction occurs between the nail pushing slider 6 and the nail box base 9, and rolling friction occurs between the nail pushing slider 6 and the nail pushing device 8. Rolling friction occurs between ...

Embodiment 2

[0035] Figure 1-8 As shown, on the one hand, this embodiment discloses a stapler pusher slider, which is applied to a laparoscopic stapler. The bottom of the pusher slider 6 is provided with several cylindrical rollers 11 perpendicular to its moving direction. The roller 11 is matched with the inner surface of the nail box base 9 on the stapler, and the nail pushing slider 6 has a working surface with a slope feature, and several working rollers 10 are arranged on the working surface, and the working rollers 10 and the stapler The lower end slope of the nail pusher 8 on the stapler is matched with the lower end slope of the nail pusher 8, and a rolling module matching the long groove 17 provided on the staple bin 5 on the stapler is also provided on the nail pusher slider 6, and the nail pusher slider 6 is along the nail. When the longitudinal axis direction of the box base 9 moves, rolling friction occurs between the nail pushing slider 6 and the nail box base 9, rolling frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com