End effector and linear anastomat

An end effector and stapler technology, applied in the field of medical devices, can solve the problems of large firing force, poor nailing effect, tissue leakage, etc., and achieve the effect of saving the firing force, improving the nailing effect, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

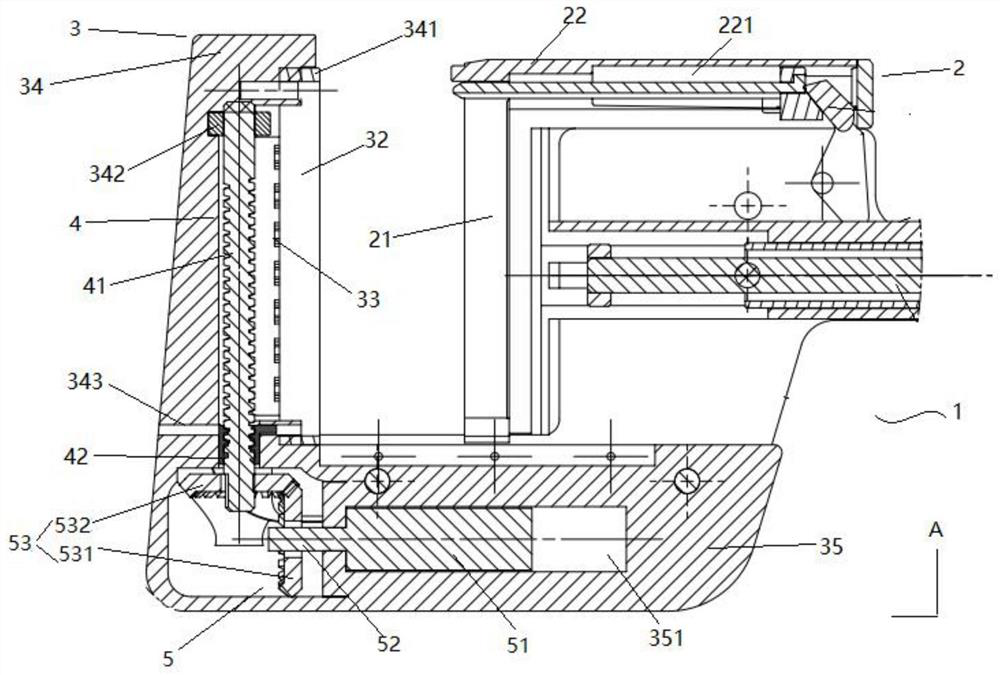

[0042] See figure 1 The end effector 1 shown in the first embodiment includes a nail anvil assembly 2 and a staple cartridge assembly 3, the staple cartridge assembly 3 includes a staple cartridge 32 for accommodating staples, and the nail anvil assembly 2 includes a Cooperating nail anvil 21. The end effector 1 of the present invention can make staples into staples sequentially. Specifically, the end effector 1 also includes a pusher assembly 4 for pushing the staples to move toward the anvil 21, and a pusher assembly 4 for driving the staples. Assembly 4 sequentially fires staples into staple firing assembly 5 .

[0043] In this embodiment, the nail pusher assembly 4 includes a screw rod 41 disposed on the nail cartridge assembly 3 and a firing nut 42 sleeved on the screw rod 41, defining the axial direction of the screw rod 41 and the firing nut 42 as the first axial direction ( figure 1 The direction of the straight line where the middle arrow A is located). The firing ...

Embodiment 2

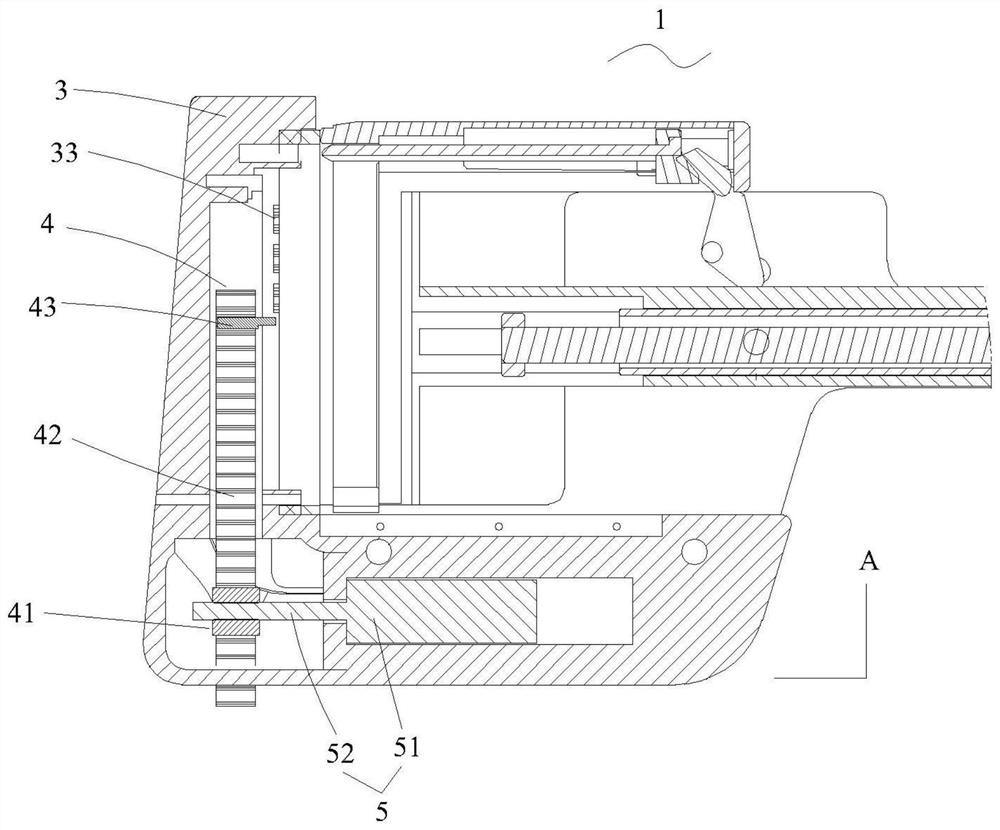

[0047] See figure 2 , the structure of the end effector shown in the second embodiment is basically the same as that shown in the first embodiment, the difference is that the pusher assembly 4 and the firing assembly 5 of the two are of different structures.

[0048] In this embodiment, the nail pusher assembly 4 includes a driving wheel 41 arranged on the nail cartridge assembly 3, a driven wheel 42, an endless belt 43 sleeved on the driving wheel 41 and the driven wheel 42, and a pusher wheel arranged on the endless belt. The nail bar 44 defines the axis direction perpendicular to the driving wheel 41 and the driven wheel 42 as the first axis direction ( figure 2 The direction of the straight line where the middle arrow A is located). The firing assembly 5 is connected to drive the drive wheel 41 to rotate, so that the endless belt 43 drives the push rod 44 to move along the first axis. The firing assembly 5 includes a firing motor 51 and a firing input shaft 52 arranged...

Embodiment 3

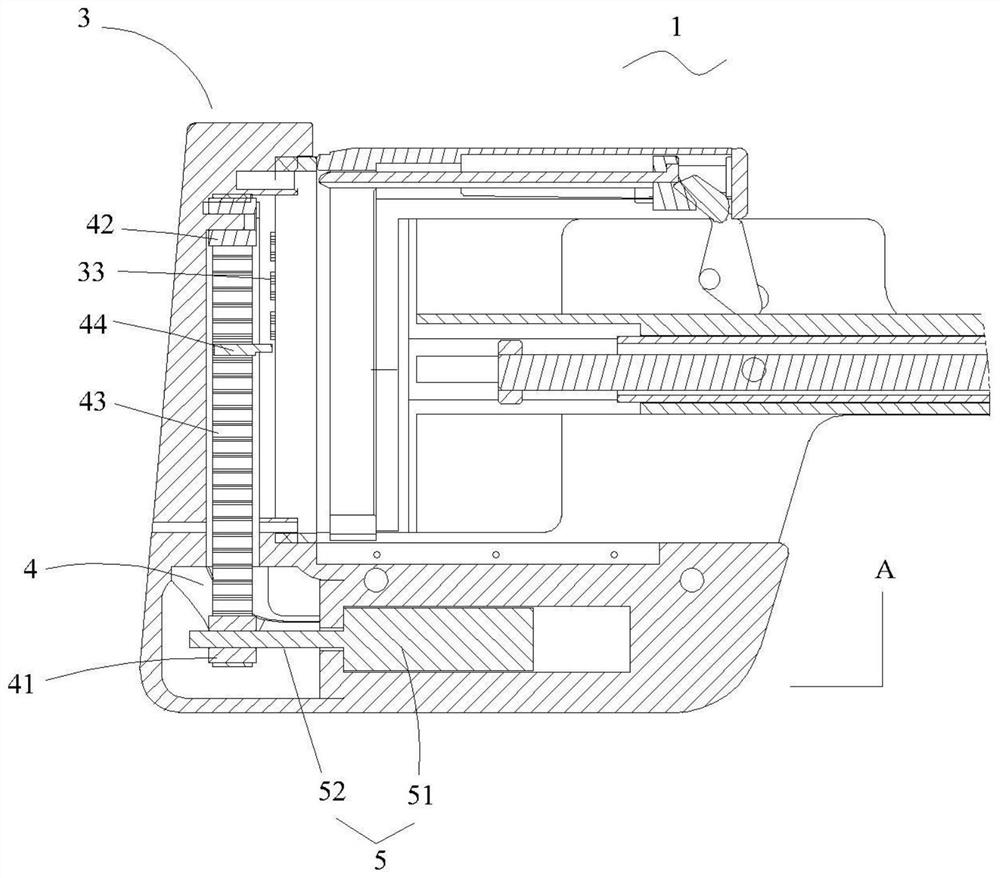

[0050] See image 3 , the structure of the end effector 1 shown in the third embodiment is basically the same as that shown in the first embodiment. The pusher rack 41 arranged on the nail cartridge assembly 3, the pusher gear 42 meshed with the pusher rack 41 and the pusher rod 43 arranged on the pusher rack 41 define an axis perpendicular to the pusher gear 42 The direction is the direction of the first axis ( image 3 The direction of the straight line where the middle arrow A is located). When the firing motor 51 in the firing assembly 5 works, the firing input shaft 52 on the firing motor 51 drives the pusher gear 42 to rotate, so that the pusher rack 41 drives the pusher rod 43 on it to move in the first axis direction , so that the pusher rod 43 triggers the pusher piece 33 to sequentially strike the staples therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com